Why All-American Production Remains A Challenge

Table of Contents

High Labor Costs and Competition from Overseas

Achieving All-American Production faces a major hurdle in the form of high labor costs and intense competition from overseas manufacturers. This disparity significantly impacts the price competitiveness of domestically produced goods.

The Wage Gap

American labor costs often significantly exceed those in other countries, particularly in developing nations with lower regulatory burdens and weaker labor protections. This creates a substantial price disadvantage for US-based businesses.

- Higher minimum wages and benefits packages: The comparatively generous benefits and higher minimum wages in the US increase production costs considerably, making it difficult to compete with lower-cost producers.

- Automation to mitigate labor costs: While automation can help mitigate some labor cost issues by increasing efficiency and reducing reliance on manual labor, the initial investment in automation technology is substantial, requiring significant capital outlay and posing a barrier to entry for many smaller manufacturers. This necessitates a careful cost-benefit analysis for businesses considering automation as a means of achieving greater price competitiveness in All-American Production.

- Reshoring initiatives: Various reshoring initiatives aim to incentivize companies to bring manufacturing back to the US, and some success has been achieved, particularly with government subsidies and tax breaks. However, the challenges of high labor costs remain a significant ongoing obstacle for the widespread implementation of reshoring and the success of All-American Production.

Global Supply Chains

Established global supply chains are deeply entrenched, making a complete shift to domestic sourcing a complex and expensive undertaking. Many businesses rely on intricate networks spanning multiple countries, optimizing for cost and efficiency. Breaking these established relationships and re-establishing domestic supply chains necessitates significant investment and restructuring.

- Limited domestic availability of components and raw materials: Many essential components and raw materials are simply not readily available domestically, forcing manufacturers to rely on imports, undermining the goal of All-American Production.

- Investment in domestic supply chains: Re-establishing domestic supply chains requires substantial investment in infrastructure, logistics, and fostering partnerships with domestic suppliers. This includes developing reliable sources for raw materials and intermediate goods, which might necessitate incentivizing domestic production of these items.

- Complexity of global supply chain restructuring: The intricate nature of global supply chains requires careful planning, substantial upfront investment, and robust risk management to minimize disruptions during the transition to a more domestically-focused approach.

Infrastructure Deficiencies and Logistics Challenges

Another significant challenge to All-American Production is the state of US infrastructure and the complexity of domestic logistics. Inefficient transportation networks increase costs and lead to delays, hindering competitiveness.

Aging Infrastructure

Outdated infrastructure, including roads, ports, and railways, adds to transportation costs and delays. Congestion in major transportation hubs exacerbates these problems.

- Need for improved infrastructure investment: Improved infrastructure investment is crucial for efficient domestic distribution of goods produced under an All-American Production model. Modernizing roads, ports, and railways is essential to reduce transportation costs and improve delivery times.

- Transportation network bottlenecks: Bottlenecks in transportation networks, such as port congestion and rail line capacity constraints, create significant delays and increase transportation costs, impacting the competitiveness of domestically manufactured goods.

- Government and private investment in infrastructure modernization: Modernizing infrastructure requires substantial government funding and private investment, often demanding a coordinated and long-term strategy to achieve meaningful improvements.

Logistics Complexity

Coordinating the movement of goods across the geographically vast US is more complex than relying on established international shipping routes. Managing domestic logistics efficiently requires robust systems and reliable partnerships.

- Finding reliable domestic transportation partners: Finding reliable and cost-effective domestic transportation partners is vital for maintaining efficient supply chains. This requires developing strong relationships with trucking companies, railroads, and other logistics providers.

- Effective inventory management: Effective inventory management is essential to avoid stockouts and minimize waste. Sophisticated inventory management systems are needed to track goods efficiently and ensure timely delivery.

- Real-time tracking and efficient logistics systems: Real-time tracking and efficient logistics systems are necessary for timely delivery and effective supply chain management. Investing in technology to improve logistics efficiency is crucial.

Skills Gap and Workforce Development

A persistent skills gap and challenges in workforce development further complicate the pursuit of All-American Production. A shortage of skilled workers and difficulty retaining talent present significant hurdles.

Lack of Skilled Labor

A shortage of skilled workers in manufacturing, particularly in specialized areas, hampers production capabilities and limits the potential for expansion of All-American Production.

- Investment in vocational training and apprenticeships: Investing in vocational training and apprenticeships is essential to address the skills gap and develop a pipeline of skilled workers for the manufacturing sector.

- Attracting young people to manufacturing careers: Attracting young people to manufacturing careers through improved education, improved working conditions, and competitive compensation is crucial for long-term growth.

- Collaboration with educational institutions: Collaborating with educational institutions to develop relevant training programs that meet the specific needs of manufacturers is essential to bridge the skills gap.

Employee Retention

Keeping skilled workers is challenging due to competition for talent and potential wage disparities with other sectors. Creating a positive and supportive work environment is crucial for retention.

- Competitive salaries and benefits packages: Offering competitive salaries and benefits packages is critical to attracting and retaining skilled workers in the manufacturing sector.

- Positive work environment: Creating a positive work environment that values employees is essential for retention and overall employee satisfaction. This includes factors such as work-life balance, opportunities for advancement, and a safe and respectful workplace.

- Investing in employee development: Investing in employee development and career advancement opportunities fosters loyalty and encourages employees to stay with the company long-term.

Conclusion

Achieving true All-American Production presents significant challenges, encompassing higher labor costs, infrastructure limitations, and workforce development hurdles. While the benefits – including job creation, enhanced national security, and reduced reliance on foreign supply chains – are compelling, overcoming these obstacles requires a multifaceted approach involving government support, private investment, and strategic planning. To build a more robust and resilient domestic manufacturing sector and achieve the benefits of All-American Production, businesses and policymakers must work together to address these complexities and explore innovative solutions, such as targeted investments in infrastructure, workforce development, and automation. Embrace the challenge of All-American Production and contribute to a stronger national economy.

Featured Posts

-

Price Gouging Allegations Surface In La Following Devastating Fires

Apr 29, 2025

Price Gouging Allegations Surface In La Following Devastating Fires

Apr 29, 2025 -

Monte Carlo Masters 2025 Tabilo Upsets Djokovic In Straight Sets

Apr 29, 2025

Monte Carlo Masters 2025 Tabilo Upsets Djokovic In Straight Sets

Apr 29, 2025 -

Parole Hearing Approaches For Ohio Doctor Convicted Of Wifes Murder 36 Years Ago

Apr 29, 2025

Parole Hearing Approaches For Ohio Doctor Convicted Of Wifes Murder 36 Years Ago

Apr 29, 2025 -

Will Republican Divisions Sink Trumps Tax Bill

Apr 29, 2025

Will Republican Divisions Sink Trumps Tax Bill

Apr 29, 2025 -

Country Music Stars Son Caretaker Claims Denied By Mother

Apr 29, 2025

Country Music Stars Son Caretaker Claims Denied By Mother

Apr 29, 2025

Latest Posts

-

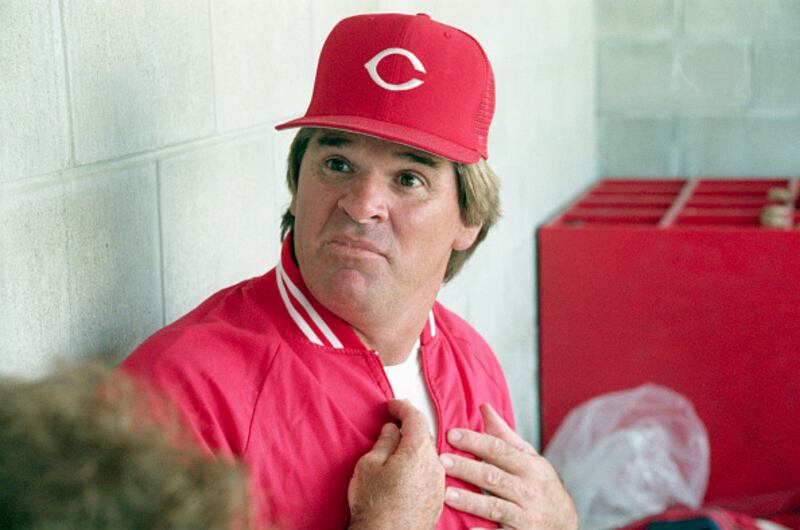

Former Mlb Star Johnny Damon Aligns With Trump On Pete Roses Hall Of Fame Eligibility

Apr 29, 2025

Former Mlb Star Johnny Damon Aligns With Trump On Pete Roses Hall Of Fame Eligibility

Apr 29, 2025 -

Damon Agrees With Trump Believes Pete Rose Deserves Hall Of Fame Spot

Apr 29, 2025

Damon Agrees With Trump Believes Pete Rose Deserves Hall Of Fame Spot

Apr 29, 2025 -

Johnny Damon Sides With Trump Advocates For Pete Roses Hall Of Fame Induction

Apr 29, 2025

Johnny Damon Sides With Trump Advocates For Pete Roses Hall Of Fame Induction

Apr 29, 2025 -

Posthumous Pardon For Pete Rose Understanding Trumps Decision

Apr 29, 2025

Posthumous Pardon For Pete Rose Understanding Trumps Decision

Apr 29, 2025 -

Snow Fox Operational Status Tuesday February 11th

Apr 29, 2025

Snow Fox Operational Status Tuesday February 11th

Apr 29, 2025