Securing Dysprosium Supplies: Strategies For A Sustainable EV Future

Table of Contents

Understanding Dysprosium's Importance in EV Manufacturing

Dysprosium, a rare earth element, possesses unique magnetic properties vital for the production of high-performance neodymium magnets. These magnets are the heart of electric vehicle motors, directly impacting their efficiency, power output, and overall range. The scarcity of dysprosium presents a significant challenge. Its limited availability creates price volatility, directly impacting the manufacturing costs and ultimately, the affordability of EVs.

- Dysprosium's contribution to motor efficiency and range: Higher-strength magnets containing dysprosium enable smaller, lighter, and more efficient EV motors, leading to improved vehicle performance and extended driving range.

- The concentration of dysprosium in permanent magnets: The optimal performance of neodymium magnets often requires a significant concentration of dysprosium, increasing dependence on its reliable supply.

- The correlation between dysprosium prices and EV manufacturing costs: Fluctuations in dysprosium prices directly translate to increased or decreased EV production costs, potentially affecting market accessibility.

Assessing Current Dysprosium Supply Chains

Currently, dysprosium production is geographically concentrated, raising significant geopolitical concerns. China holds a dominant position in the global dysprosium market, controlling a significant portion of mining and processing. This concentration creates vulnerabilities, including:

- Geographical distribution of dysprosium mines: A significant portion of dysprosium mining operations are located in a limited number of countries, primarily in China and a few other nations.

- Major dysprosium-producing countries and their political stability: Reliance on politically unstable regions for dysprosium supply presents a risk of disruptions due to political conflicts or policy changes.

- Potential risks of relying on a single supplier or region: Over-reliance on one supplier or region exposes the EV industry to price manipulation, supply chain disruptions, and potential trade wars.

Strategies for Diversifying Dysprosium Sources

Diversifying dysprosium sources is crucial for mitigating supply chain risks. Several strategies can be employed:

- Exploring and developing new dysprosium mines: Investment in exploration and development of new mines in diverse geographical locations, adopting sustainable mining practices, is crucial for reducing reliance on existing sources. This includes adhering to stringent environmental regulations and prioritizing responsible resource management.

- Investing in research and development: Improving dysprosium extraction and processing techniques through technological advancements can significantly enhance efficiency and reduce environmental impact. This includes optimizing the separation of dysprosium from other rare earth elements and developing cleaner processing methods.

- Recycling and urban mining: Recycling dysprosium from end-of-life EVs and other electronic waste offers a significant opportunity to secure supplies while promoting a circular economy. Developing effective and economically viable recycling programs is essential.

- Government policies to incentivize domestic dysprosium production: Governments can play a key role in fostering domestic dysprosium production through tax incentives, subsidies, and streamlined permitting processes.

- Technological advancements in dysprosium extraction and refining: Continued research into innovative extraction and refining methods can improve efficiency and reduce environmental impact.

- The economic viability of dysprosium recycling programs: Investment in research and infrastructure is crucial for creating economically viable recycling programs, making it profitable to recover dysprosium from waste streams.

Implementing Sustainable Dysprosium Management Practices

Sustainable dysprosium management is paramount. This requires adopting environmentally responsible practices throughout the entire supply chain:

- Environmentally responsible mining and processing methods: Minimizing the environmental impact of dysprosium extraction through responsible mining techniques, water management, and waste reduction is essential.

- Circular economy principles: Designing EV components for recyclability, including magnets containing dysprosium, allows for the efficient recovery and reuse of this critical material.

- International cooperation: Collaborative initiatives between governments, industry, and researchers are necessary to establish global standards for sustainable dysprosium management.

- Environmental regulations and certifications for dysprosium mining: Stringent regulations and certifications can ensure environmentally responsible mining practices.

- Best practices for minimizing waste and pollution during dysprosium processing: Adopting best practices in processing can significantly reduce environmental pollution.

- International agreements on responsible rare earth element sourcing: International agreements can help establish global standards for responsible sourcing of rare earth elements.

Technological Advancements to Reduce Dysprosium Dependence

Reducing reliance on dysprosium requires technological innovation:

- Alternative magnet technologies: Research and development of dysprosium-free magnets or magnets utilizing alternative rare earth elements can reduce dependence on this critical material.

- Advanced motor designs: Improving motor efficiency through advanced designs can reduce the overall demand for rare earth magnets, lessening the impact of dysprosium scarcity.

- Research and development of dysprosium-free magnet materials: Significant investment in R&D is crucial for developing viable alternatives to dysprosium-containing magnets.

- Technological advancements in motor design and efficiency: Innovations in motor design can reduce the amount of rare earth magnets needed for optimal performance.

- Potential breakthroughs in energy storage technologies: Advancements in battery technology may reduce the reliance on high-performance magnets in EVs.

Conclusion

Securing dysprosium supplies is vital for a sustainable EV future. Diversifying sources, implementing sustainable practices, and fostering technological innovation are crucial for mitigating risks and ensuring a reliable supply of this critical material. International collaboration and responsible management are essential for navigating the challenges and realizing the opportunities presented by this critical resource. Learn more about the initiatives aimed at securing dysprosium supplies and contribute to a sustainable EV future. Join the conversation and support responsible rare earth element management today!

Featured Posts

-

Manufacturing In America Obstacles And Opportunities

Apr 29, 2025

Manufacturing In America Obstacles And Opportunities

Apr 29, 2025 -

Black Hawk Crash Pilot Ignored Instructors Warnings Report Reveals

Apr 29, 2025

Black Hawk Crash Pilot Ignored Instructors Warnings Report Reveals

Apr 29, 2025 -

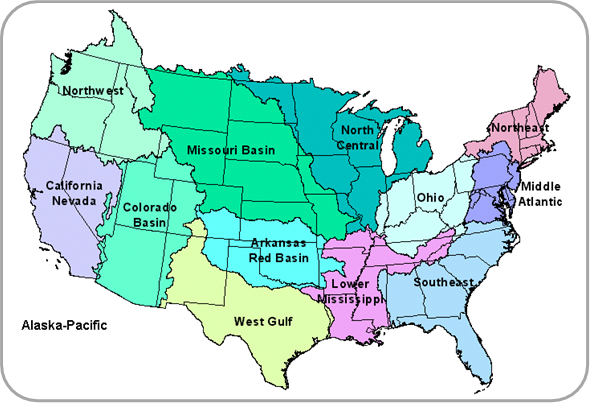

Understanding The Ccp United Fronts Activities In Minnesota

Apr 29, 2025

Understanding The Ccp United Fronts Activities In Minnesota

Apr 29, 2025 -

Kentuckys Severe Weather Awareness Week What The Nws Wants You To Know

Apr 29, 2025

Kentuckys Severe Weather Awareness Week What The Nws Wants You To Know

Apr 29, 2025 -

Blue Origin Postpones Launch Vehicle Subsystem Issue Reported

Apr 29, 2025

Blue Origin Postpones Launch Vehicle Subsystem Issue Reported

Apr 29, 2025

Latest Posts

-

Milly Alcock As Supergirl In Netflixs Sirens A Look At The New Trailer

Apr 29, 2025

Milly Alcock As Supergirl In Netflixs Sirens A Look At The New Trailer

Apr 29, 2025 -

Supergirl Milly Alcock Joins Julianne Moores Cult In Netflixs Sirens Trailer

Apr 29, 2025

Supergirl Milly Alcock Joins Julianne Moores Cult In Netflixs Sirens Trailer

Apr 29, 2025 -

Tremor 2 Netflix Series Kevin Bacons Potential Return Explored

Apr 29, 2025

Tremor 2 Netflix Series Kevin Bacons Potential Return Explored

Apr 29, 2025 -

A Tremors Series For Netflix What We Know So Far

Apr 29, 2025

A Tremors Series For Netflix What We Know So Far

Apr 29, 2025 -

Is Tremors Returning To Netflix Updates And Rumors

Apr 29, 2025

Is Tremors Returning To Netflix Updates And Rumors

Apr 29, 2025