Manufacturing In America: Obstacles And Opportunities

Table of Contents

Obstacles Facing American Manufacturing

American manufacturing faces a confluence of challenges that hinder its ability to fully compete on the global stage. These obstacles demand innovative solutions and strategic investments to overcome.

Rising Labor Costs and Skills Gap

One of the most significant hurdles is the rising cost of labor in the US compared to global competitors. This, coupled with a critical shortage of skilled workers, creates a significant impediment to growth. Many manufacturing jobs require specialized skills, and finding qualified machinists, welders, and engineers is increasingly difficult.

- Higher wages compared to global competitors: The higher minimum wage and benefits packages in the US make it more expensive to manufacture goods domestically compared to countries with lower labor costs.

- Difficulty filling skilled technician roles: A significant skills gap exists, with a shortage of experienced and qualified technicians across various manufacturing disciplines. This impacts productivity and efficiency.

- Lack of robust apprenticeship programs: The decline in traditional apprenticeship programs has contributed to the shortage of skilled labor, hindering the pipeline of new talent entering the manufacturing sector.

- Need for upskilling and reskilling initiatives: Investing in robust workforce development programs is crucial, providing opportunities for upskilling and reskilling the existing workforce to meet the demands of modern manufacturing. This includes incorporating automation solutions and robotics training.

Supply Chain Disruptions and Dependence on Global Sources

For decades, many American manufacturers relied heavily on global supply chains, often sourcing raw materials and components from overseas. This dependence has proven vulnerable, exposing the fragility of just-in-time manufacturing models.

- Increased transportation costs: The reliance on global sourcing leads to increased transportation costs and extended lead times, particularly with the recent rise in fuel prices and global shipping disruptions.

- Geopolitical instability impacting supply chains: Geopolitical instability and unexpected events (like pandemics or natural disasters) can severely disrupt global supply chains, causing delays and shortages.

- Delays and shortages of raw materials and components: Supply chain disruptions can lead to significant delays and shortages of critical materials, halting production and impacting profitability.

- The push for reshoring and nearshoring: Businesses are increasingly exploring reshoring (bringing manufacturing back to the US) and nearshoring (moving manufacturing to nearby countries) to mitigate risks and improve supply chain resilience.

Intense Competition and Globalization

American manufacturers face fierce competition from international companies, particularly those based in countries with lower labor costs and less stringent regulations.

- Competition from low-cost countries: Manufacturers in countries with lower labor costs, such as China and Vietnam, can often produce goods at significantly lower prices, creating intense competitive pressure.

- Global trade agreements and tariffs impacting competitiveness: Global trade agreements and tariffs can significantly impact the competitiveness of American manufacturers, influencing pricing and market access.

- Need for innovation and differentiation: To thrive in this competitive landscape, American manufacturers need to focus on innovation, developing unique products and processes that offer a competitive advantage. This includes embracing Industry 4.0 technologies.

Opportunities for Growth in American Manufacturing

Despite the challenges, significant opportunities exist for growth and revitalization within the American manufacturing sector. By strategically addressing these opportunities, the US can strengthen its manufacturing base and enhance its global competitiveness.

Reshoring and Nearshoring Initiatives

The trend of reshoring and nearshoring presents a significant opportunity for American manufacturers. Bringing production closer to home offers several key advantages:

- Reduced transportation costs and lead times: Reshoring and nearshoring significantly reduce transportation costs and lead times, improving efficiency and responsiveness to market demands.

- Improved supply chain security: Reduced reliance on global supply chains enhances supply chain security, mitigating risks associated with geopolitical instability and unforeseen events.

- Enhanced quality control: Greater control over the manufacturing process allows for enhanced quality control and improved product consistency.

- Support for local economies: Reshoring and nearshoring initiatives create jobs and stimulate economic growth in local communities.

Technological Advancements and Automation

Embracing technological advancements is critical for boosting efficiency and productivity in American manufacturing. Automation plays a crucial role:

- Adoption of robotics and automation: Implementing robotics and automation solutions can significantly improve productivity, reduce labor costs, and enhance precision.

- Use of AI and machine learning in manufacturing processes: Artificial intelligence and machine learning are revolutionizing manufacturing processes, enabling predictive maintenance, quality control optimization, and improved efficiency.

- Advanced manufacturing technologies: Adoption of advanced manufacturing technologies, such as additive manufacturing (3D printing) and advanced materials, unlocks new possibilities for product development and customization.

- Increased precision and efficiency: Automation and technological advancements contribute to increased precision and efficiency in manufacturing processes, reducing waste and improving product quality.

Government Policies and Incentives

Government support plays a crucial role in fostering growth within the manufacturing sector. Strategic investments and supportive policies can significantly impact competitiveness:

- Tax breaks and incentives for domestic manufacturing: Government tax breaks and incentives can encourage companies to invest in domestic manufacturing facilities and create jobs.

- Investments in infrastructure: Investments in infrastructure, including transportation and energy infrastructure, are essential for supporting the growth of American manufacturing.

- Research and development funding: Funding for research and development in advanced manufacturing technologies is crucial for maintaining a competitive edge.

- Workforce training programs: Government-supported workforce training programs are critical for developing and retaining a skilled manufacturing workforce.

Conclusion

The future of manufacturing in America hinges on effectively addressing the existing challenges while seizing the considerable opportunities. Overcoming the skills gap, strengthening supply chains through reshoring and nearshoring, and embracing technological advancements such as automation in manufacturing are crucial steps. Government support, including manufacturing incentives and investments in infrastructure and workforce development, plays a significant role in this revitalization. Investing in American manufacturing is investing in the future of the US economy. Explore the possibilities and contribute to the growth of manufacturing in America. Learn more about reshoring initiatives and the latest advancements in American manufacturing today!

Featured Posts

-

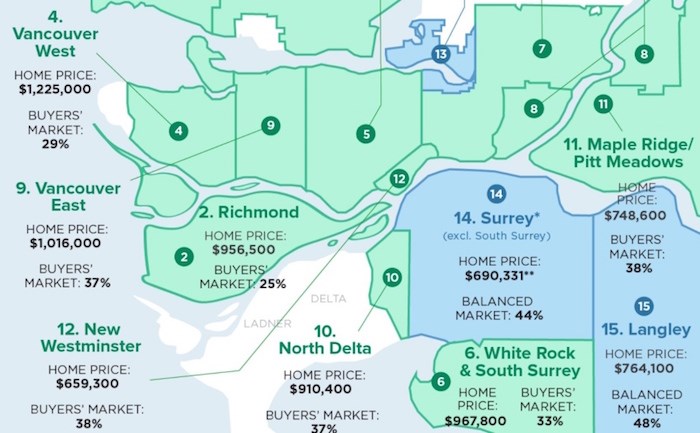

Pace Of Rent Increases Slows In Metro Vancouver Housing Costs Remain High

Apr 29, 2025

Pace Of Rent Increases Slows In Metro Vancouver Housing Costs Remain High

Apr 29, 2025 -

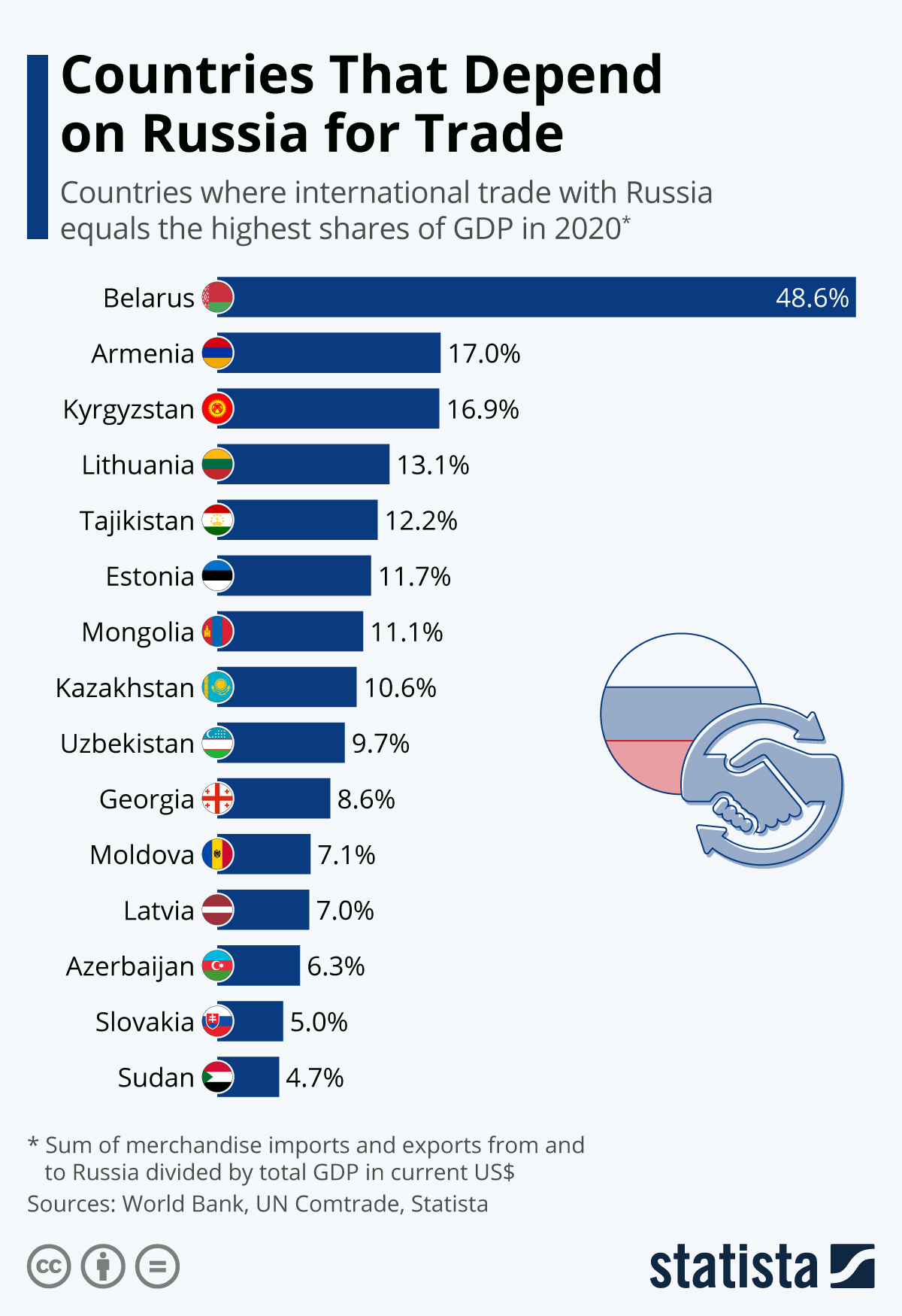

Hungarys Economic Ties With China A Stand Against Us Influence

Apr 29, 2025

Hungarys Economic Ties With China A Stand Against Us Influence

Apr 29, 2025 -

Parole Hearing Approaches For Ohio Doctor Convicted Of Wifes Murder 36 Years Ago

Apr 29, 2025

Parole Hearing Approaches For Ohio Doctor Convicted Of Wifes Murder 36 Years Ago

Apr 29, 2025 -

American Expat Life In Spain One Returned One Stayed Why

Apr 29, 2025

American Expat Life In Spain One Returned One Stayed Why

Apr 29, 2025 -

Solve Nyt Strands Hints And Answers For March 3 2025 Puzzle

Apr 29, 2025

Solve Nyt Strands Hints And Answers For March 3 2025 Puzzle

Apr 29, 2025

Latest Posts

-

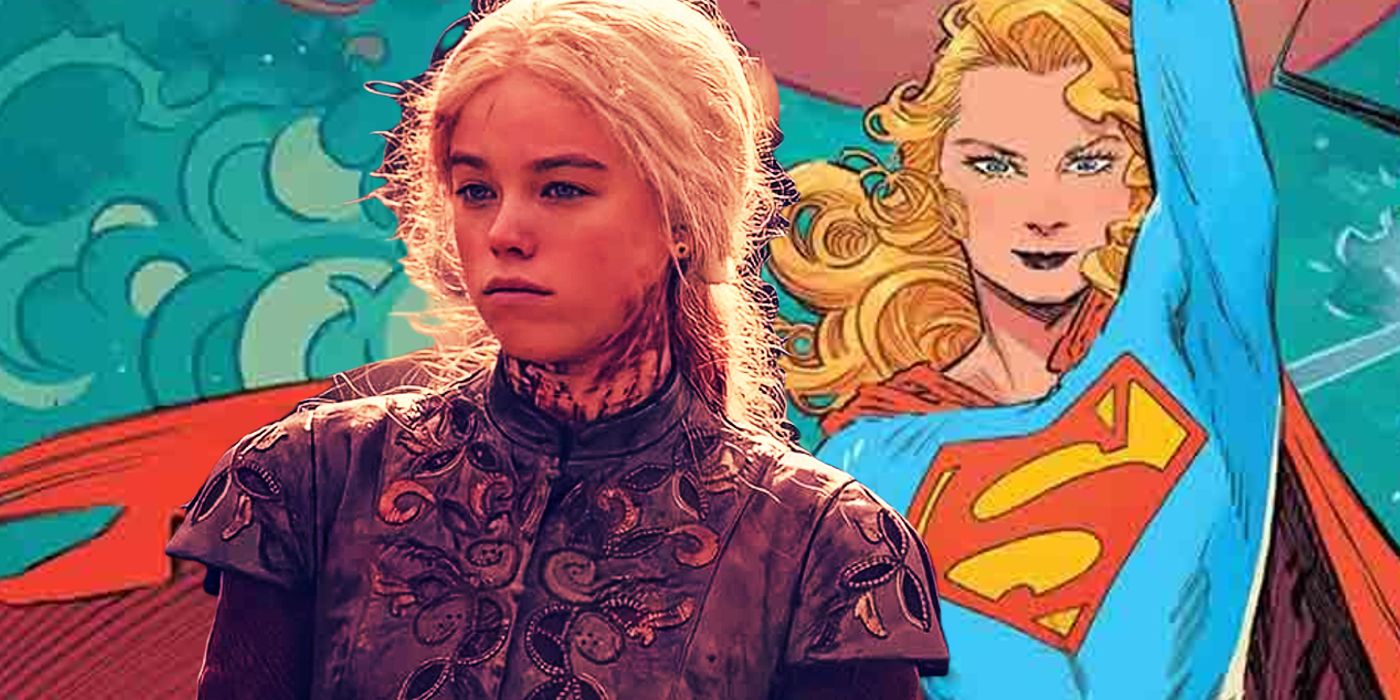

Milly Alcock As Supergirl In Netflixs Sirens A Look At The New Trailer

Apr 29, 2025

Milly Alcock As Supergirl In Netflixs Sirens A Look At The New Trailer

Apr 29, 2025 -

Supergirl Milly Alcock Joins Julianne Moores Cult In Netflixs Sirens Trailer

Apr 29, 2025

Supergirl Milly Alcock Joins Julianne Moores Cult In Netflixs Sirens Trailer

Apr 29, 2025 -

Tremor 2 Netflix Series Kevin Bacons Potential Return Explored

Apr 29, 2025

Tremor 2 Netflix Series Kevin Bacons Potential Return Explored

Apr 29, 2025 -

A Tremors Series For Netflix What We Know So Far

Apr 29, 2025

A Tremors Series For Netflix What We Know So Far

Apr 29, 2025 -

Is Tremors Returning To Netflix Updates And Rumors

Apr 29, 2025

Is Tremors Returning To Netflix Updates And Rumors

Apr 29, 2025