Examining The Potential For A Resurgence Of American Factory Jobs

Table of Contents

The Reshoring Phenomenon and its Impact on US Manufacturing

Reshoring, the process of bringing manufacturing operations back to the United States from overseas locations, is a crucial component of the potential resurgence of American factory jobs. Several powerful forces are driving this trend. Rising labor costs in countries like China, coupled with increasing transportation expenses, are making overseas manufacturing less attractive. Furthermore, recent supply chain disruptions, exacerbated by global events, have highlighted the vulnerabilities of relying heavily on offshore production. Geopolitical instability further adds to the risk and uncertainty of maintaining manufacturing operations abroad. Finally, growing consumer demand for domestically produced goods, driven by a desire for greater quality control, shorter lead times, and support for American jobs, is creating a powerful incentive for companies to reshore.

Companies like Whirlpool and General Electric have already begun to reshore parts of their manufacturing operations, underscoring the viability of this trend. The benefits are numerous:

- Reduced transportation costs and lead times: Shipping goods across continents is expensive and time-consuming. Reshoring significantly reduces these costs and allows for faster delivery.

- Improved quality control and product customization: Domestic manufacturing provides greater control over the production process, leading to higher quality products and the ability to offer more customized options.

- Enhanced brand image and consumer trust: "Made in America" carries a strong appeal to many consumers, boosting brand image and fostering trust.

- Potential for increased domestic economic growth: Reshoring creates jobs, stimulates local economies, and contributes to overall economic growth.

The Role of Automation and Technological Advancements

Automation and robotics are transforming the manufacturing landscape, impacting the nature of factory jobs. While concerns about job displacement exist, it's crucial to recognize the potential for automation to increase efficiency and productivity. This increased productivity can lead to the creation of new high-skilled jobs in areas such as robotics engineering, software development, and data analytics. These roles require specialized skills in programming, maintenance, and system optimization.

Addressing the anxieties around job displacement is crucial. Retraining and upskilling programs are essential to equip workers with the skills needed for these new roles. This transition requires significant investment in education and training initiatives, focused on bridging the gap between the skills of the existing workforce and the demands of advanced manufacturing.

- Increased productivity and output: Automation allows factories to produce more goods with fewer workers, increasing efficiency.

- Improved safety and reduced workplace accidents: Robots can handle dangerous or repetitive tasks, improving workplace safety.

- Creation of new high-skilled jobs: The demand for skilled technicians and engineers to design, implement, and maintain automated systems will grow.

- Need for investment in worker training and education: Upskilling and reskilling initiatives are essential to prepare the workforce for the changing landscape.

Government Policies and Incentives Supporting Manufacturing Growth

Government policies play a significant role in fostering domestic manufacturing growth. Tax incentives, grants, and subsidies can attract businesses to invest in US manufacturing facilities. These incentives often target specific sectors or technologies, encouraging innovation and the adoption of advanced manufacturing techniques. Trade policies, including tariffs, can also protect domestic industries from unfair foreign competition, leveling the playing field for American manufacturers. Furthermore, government investment in infrastructure projects, such as improved transportation networks and access to high-speed internet, can create the supportive environment needed for manufacturing hubs to thrive.

- Tax credits for businesses investing in manufacturing facilities: Financial incentives encourage companies to build and expand their operations in the US.

- Grants for research and development in advanced manufacturing technologies: Funding for innovation keeps American manufacturers at the cutting edge.

- Tariffs to protect domestic industries from foreign competition: Tariffs can safeguard American jobs by making imported goods more expensive.

- Government-funded infrastructure projects to support manufacturing hubs: Improved infrastructure makes it easier and cheaper for businesses to operate.

Developing a Skilled Workforce for the Modern Factory

A skilled workforce is paramount to a successful manufacturing resurgence. Initiatives to enhance STEM education (Science, Technology, Engineering, and Mathematics) are crucial for creating a pipeline of talent capable of filling the high-skilled jobs created by advanced manufacturing. Similarly, expanding vocational training programs and apprenticeships provides hands-on experience, bridging the gap between theoretical knowledge and practical application. Partnerships between educational institutions and businesses are essential for ensuring that training programs align with the specific needs of the industry. A commitment to lifelong learning and reskilling opportunities ensures that workers can adapt to the evolving demands of the manufacturing sector.

- Investing in STEM education at all levels: A strong foundation in STEM subjects is essential for success in advanced manufacturing.

- Expanding apprenticeship and vocational training programs: Practical training provides the skills needed for immediate employment.

- Partnerships between educational institutions and businesses: Collaboration ensures that training programs meet industry needs.

- Promoting lifelong learning and reskilling opportunities: Workers need ongoing training to adapt to technological advancements.

The Future of American Factory Jobs – A Resurgence on the Horizon?

The potential for a resurgence of American factory jobs is real, driven by a powerful combination of reshoring, automation, supportive government policies, and a commitment to workforce development. While automation will undeniably transform the nature of work, the creation of new, high-skilled jobs and the opportunity to bring manufacturing back to the US represent a significant economic opportunity. Addressing the challenges posed by automation through robust retraining and upskilling initiatives is crucial to ensure a smooth transition and a thriving manufacturing sector. Explore the potential for a resurgence of American factory jobs and how you can contribute to this exciting evolution.

Featured Posts

-

Hl Ymkn Lldhkae Alastnaey Ktabt Rwayat Jdydt Laghatha Krysty

May 20, 2025

Hl Ymkn Lldhkae Alastnaey Ktabt Rwayat Jdydt Laghatha Krysty

May 20, 2025 -

Burnham And Highbridge History Unveiled Photo Archive Opens

May 20, 2025

Burnham And Highbridge History Unveiled Photo Archive Opens

May 20, 2025 -

Michael Schumacher Viaje En Helicoptero De Mallorca A Suiza Para Ver A Su Nieta

May 20, 2025

Michael Schumacher Viaje En Helicoptero De Mallorca A Suiza Para Ver A Su Nieta

May 20, 2025 -

Agatha Christies Towards Zero Episode 1 A Murder Free Mystery

May 20, 2025

Agatha Christies Towards Zero Episode 1 A Murder Free Mystery

May 20, 2025 -

Guide Des Nouveaux Chefs Et Restaurants De Biarritz

May 20, 2025

Guide Des Nouveaux Chefs Et Restaurants De Biarritz

May 20, 2025

Latest Posts

-

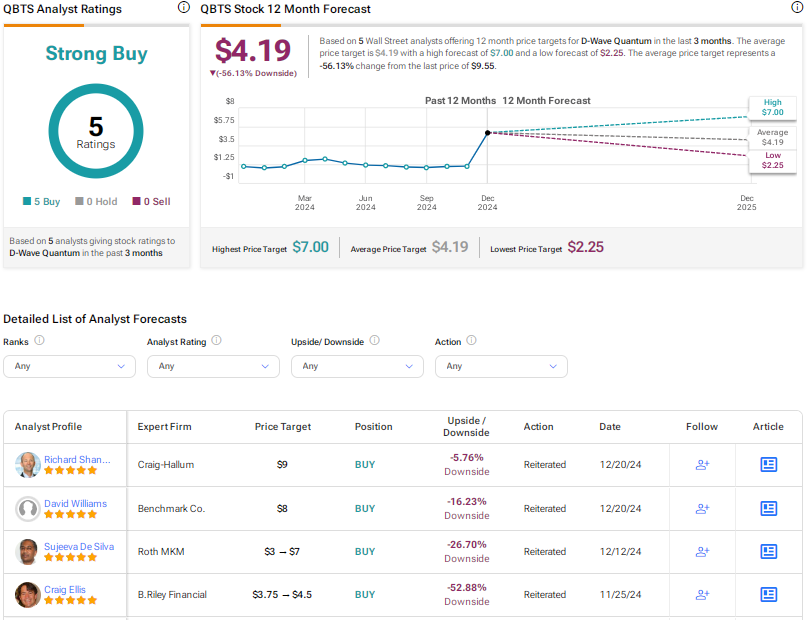

D Wave Quantum Inc Qbts Stock Plunge In 2025 Reasons For The Decline

May 20, 2025

D Wave Quantum Inc Qbts Stock Plunge In 2025 Reasons For The Decline

May 20, 2025 -

Qbts Stock Predicting The Earnings Report Impact

May 20, 2025

Qbts Stock Predicting The Earnings Report Impact

May 20, 2025 -

D Wave Quantum Qbts Stock Analyzing Mondays Significant Price Drop

May 20, 2025

D Wave Quantum Qbts Stock Analyzing Mondays Significant Price Drop

May 20, 2025 -

D Wave Quantum Qbts Stock Crash Mondays Market Reaction Explained

May 20, 2025

D Wave Quantum Qbts Stock Crash Mondays Market Reaction Explained

May 20, 2025 -

D Wave Quantum Inc Qbts Stock Plunge Understanding Mondays Crash

May 20, 2025

D Wave Quantum Inc Qbts Stock Plunge Understanding Mondays Crash

May 20, 2025