BYD's EV Battery Manufacturing Leadership: A Case Study Addendum

Table of Contents

BYD's Blade Battery Technology: A Game Changer

BYD's Blade Battery technology represents a significant leap forward in EV battery technology. Unlike traditional cylindrical or prismatic cells, the Blade Battery uses a unique elongated cell design, integrating seamlessly into the vehicle's chassis. This innovative approach offers several key advantages:

- Increased energy density: The Blade Battery achieves higher energy density compared to many traditional lithium-ion batteries, resulting in a longer driving range for EVs. This is partly due to its use of lithium iron phosphate (LFP) chemistry.

- Enhanced safety features: The Blade Battery's design significantly improves safety. Its unique structure and inherent thermal stability minimize the risk of thermal runaway, a major concern with some battery chemistries.

- Improved structural integration: The Blade Battery's flat shape allows for efficient integration into the vehicle's chassis, contributing to increased vehicle rigidity and improved overall vehicle design.

- Cost-effectiveness: Utilizing LFP chemistry and streamlined manufacturing processes makes the Blade Battery more cost-effective than some competing technologies, enhancing BYD's competitiveness in the EV market.

The impact of Blade Battery technology on BYD's market position has been substantial. Its superior energy density and safety features have attracted numerous customers, contributing significantly to BYD's sales growth and strengthening its competitive advantage in the rapidly expanding EV battery market.

Vertical Integration and Supply Chain Management in BYD's EV Battery Production

BYD's success is significantly attributed to its vertically integrated approach to EV battery production. The company controls virtually the entire production process, from sourcing raw materials like lithium and cobalt to manufacturing the final battery packs. This strategy offers several crucial benefits:

- Reduced reliance on external suppliers: Vertical integration minimizes dependency on third-party suppliers, mitigating supply chain risks and ensuring a consistent supply of components.

- Improved cost control and efficiency: By managing each stage of production, BYD can optimize costs and streamline operations, resulting in greater efficiency and competitiveness.

- Enhanced quality control: Direct control over the entire production process allows BYD to implement stringent quality control measures at every stage, ensuring high product quality and reliability.

- Faster response to market demands: The integrated system allows BYD to quickly adapt to changing market demands and introduce new products more efficiently.

This strategic vertical integration provides a significant competitive edge, enhancing BYD's resilience and responsiveness in a dynamic and competitive EV battery market. Its supply chain optimization is a key factor in its ability to scale production rapidly and meet growing global demand.

BYD's Global Expansion and Market Share in EV Battery Manufacturing

BYD's global expansion strategy has been instrumental in its rise to prominence in the EV battery manufacturing sector. The company has steadily increased its market share, penetrating key markets worldwide:

- Key markets: BYD is making significant inroads in China, Europe, and other regions, establishing itself as a major player in numerous international markets.

- Partnerships and collaborations: BYD actively collaborates with other automakers and technology companies, expanding its reach and market influence.

- Future expansion plans: BYD continues to invest heavily in expanding its manufacturing capacity and developing new technologies, aiming to further consolidate its global market leadership.

Data indicates a dramatic increase in BYD's global market share over recent years, solidifying its position as a dominant force in the global EV battery market. Its international competition is being left behind by this rapid growth.

Sustainability and Environmental Impact of BYD's EV Battery Production

BYD is committed to sustainable manufacturing practices, recognizing the environmental responsibility inherent in large-scale battery production. The company actively works to minimize its environmental impact through:

- Renewable energy sources: BYD utilizes renewable energy sources in its manufacturing plants, significantly reducing its carbon footprint.

- Battery recycling: BYD is investing heavily in battery recycling and responsible disposal of battery components, promoting a circular economy model.

- Supply chain sustainability: The company actively works to reduce carbon emissions throughout its supply chain, promoting sustainable sourcing of raw materials.

BYD’s focus on sustainable manufacturing, coupled with its adoption of LFP batteries (which have a smaller environmental impact than some other battery chemistries), positions the company as a leader in environmentally responsible EV battery production. Its green technology approach is a key differentiator in a growing market increasingly conscious of sustainability.

Conclusion: The Future of BYD's EV Battery Manufacturing Leadership

BYD's success in EV battery manufacturing stems from a confluence of factors: groundbreaking Blade Battery technology, a strategically implemented vertical integration approach, aggressive global expansion, and a strong commitment to sustainability. These key elements have propelled BYD to a position of market dominance and established it as a key player shaping the future of electric mobility. BYD's innovative battery solutions are not only improving the performance and affordability of electric vehicles but are also contributing to a more sustainable future. Stay informed about the ongoing advancements in BYD's EV battery manufacturing leadership by following industry news and exploring their latest innovations on their website. Learn more about BYD's commitment to sustainable and innovative EV battery solutions at [link to BYD website].

Featured Posts

-

Police Continue Search For Missing Woman In Portola Valley Preserve

May 13, 2025

Police Continue Search For Missing Woman In Portola Valley Preserve

May 13, 2025 -

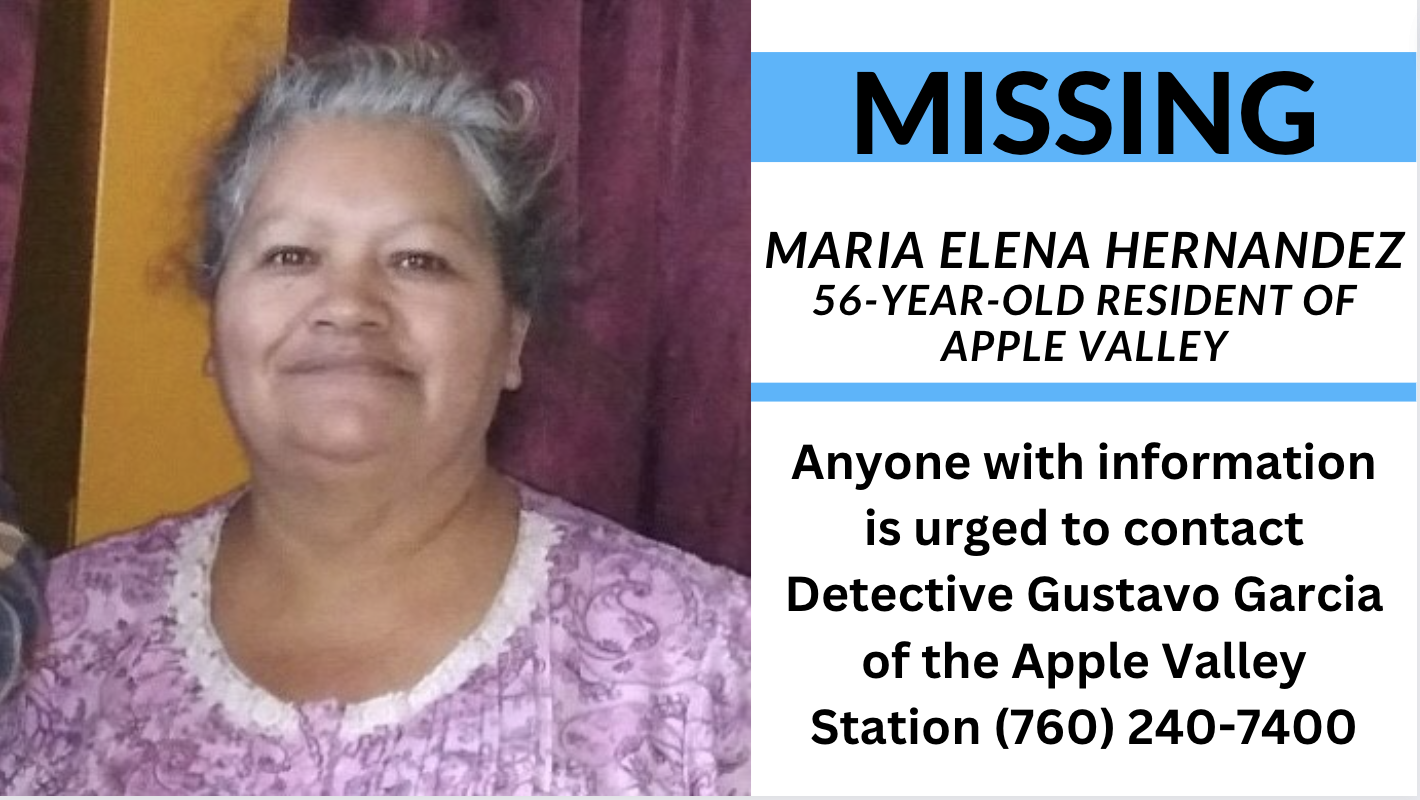

Building Voice Assistants Made Easy Open Ais 2024 Developer Showcase

May 13, 2025

Building Voice Assistants Made Easy Open Ais 2024 Developer Showcase

May 13, 2025 -

Okc Thunders Draft Pick Uncertainty Persists After Seasons End

May 13, 2025

Okc Thunders Draft Pick Uncertainty Persists After Seasons End

May 13, 2025 -

Alimenty I Skandal Pravda O Syne Tatyany Kadyshevoy

May 13, 2025

Alimenty I Skandal Pravda O Syne Tatyany Kadyshevoy

May 13, 2025 -

Aryan Sabalenka Reaches Italian Open Round Of 32

May 13, 2025

Aryan Sabalenka Reaches Italian Open Round Of 32

May 13, 2025