Why Robots Struggle To Replicate Human Skill In Nike Sneaker Production

Table of Contents

The Intricacies of Sneaker Assembly

The seemingly simple act of assembling a Nike sneaker involves a surprisingly complex series of operations demanding exceptional dexterity and precision.

Dexterity and Precision

Creating a Nike sneaker requires incredibly fine motor skills. Consider the tasks involved:

- Precise stitching: Creating the intricate stitching patterns on the upper requires consistent tension and needle control – something current robotic systems struggle to consistently replicate.

- Accurate glue application: The precise application of adhesives is crucial for structural integrity and a flawless finish. Too much, and the shoe is bulky; too little, and it falls apart.

- Attaching the swoosh logo: Perfectly placing the iconic swoosh requires exceptional precision and accuracy, a challenge for robots lacking the adaptability of human hands.

Current robotic technology, while advancing rapidly, still lacks the nuanced dexterity and precision needed for these tasks. Human hands possess an unmatched combination of strength, sensitivity, and adaptability that robots haven't yet mastered.

Material Handling and Variability

Nike sneakers use a variety of materials – leather, suede, mesh, synthetic fabrics – each with its own unique texture, thickness, and properties. This presents significant challenges for automated systems.

- Automated material feeding: Consistently feeding diverse materials into robotic systems presents challenges in terms of material flow and handling. Variations in material thickness and texture can lead to jams and inaccuracies.

- Consistent pressure application: Applying the correct amount of pressure during stitching, gluing, and other processes is critical. Inconsistent pressure can lead to poor quality and defects.

Human workers possess the judgment to adapt to material imperfections and inconsistencies. They can adjust their technique based on the specific material, ensuring a consistent and high-quality outcome.

The Role of Human Creativity and Innovation

Beyond the purely technical aspects, human creativity and problem-solving skills are essential for efficient and high-quality Nike sneaker production.

Adaptability and Problem-Solving

Unexpected issues frequently arise during manufacturing. Human workers can quickly adapt and find creative solutions on the spot.

- Addressing material defects: A slight imperfection in a piece of leather can be easily addressed by a skilled worker, but it can cause a robotic system to malfunction.

- Modifying assembly techniques: Sometimes, a slightly different approach is needed to address a specific problem. Human workers can easily improvise, while robots require reprogramming.

Robots currently lack the adaptability and intuitive problem-solving capabilities of human workers, limiting their effectiveness in addressing unexpected challenges.

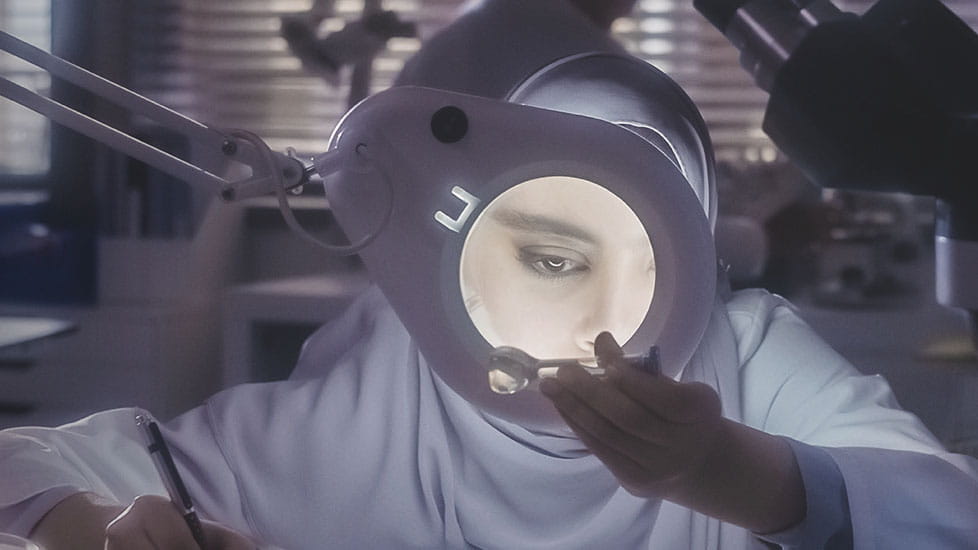

Quality Control and Inspection

Human inspectors play a crucial role in maintaining Nike's high quality standards.

- Subtle defect identification: Human visual inspection and tactile assessment can identify subtle defects that automated systems might miss.

- Consistency assurance: Human inspectors ensure consistent quality across all sneakers, identifying inconsistencies that might slip past automated systems.

Current automated quality control systems are limited in their ability to detect the nuances that a human eye and hand can readily identify.

Economic and Practical Limitations

While the benefits of robotic automation are clear in many industries, implementing it in Nike sneaker production faces significant economic and practical hurdles.

High Initial Investment Costs

The cost of advanced robotic systems for sneaker production is substantial.

- High capital expenditure: Implementing these systems involves a significant upfront investment in equipment, software, and specialized training.

- Return on investment (ROI): The ROI of robotic systems can be uncertain, particularly in a labor-intensive industry like sneaker manufacturing. The high initial cost needs to be weighed against the potential savings in labor costs.

Programming and Maintenance Complexity

Programming and maintaining complex robotic systems are challenging and resource-intensive.

- Specialized skills: Operating and maintaining these systems requires specialized skills and expertise, leading to increased labor costs.

- Downtime and maintenance: Robotic systems can experience downtime due to malfunctions, requiring costly repairs and maintenance.

Conclusion

In summary, challenges in replicating human expertise in Nike sneaker manufacturing stem from the intricate nature of sneaker assembly, the crucial role of human creativity and problem-solving, and the significant economic and practical limitations of current robotic technology. While advancements in robotics may eventually address some of these limitations, the unique combination of dexterity, adaptability, and judgment inherent in human craftsmanship remains a significant hurdle for full robotic automation in this specialized field. Learn more about the ongoing quest to improve robotic automation in the face of the enduring complexities of replicating human skill in Nike sneaker production.

Featured Posts

-

Supreme Court Obamacare Case Trumps Role And Potential Impact On Rfk Jr

Apr 22, 2025

Supreme Court Obamacare Case Trumps Role And Potential Impact On Rfk Jr

Apr 22, 2025 -

Pope Francis Dead At 88 Following Pneumonia Battle

Apr 22, 2025

Pope Francis Dead At 88 Following Pneumonia Battle

Apr 22, 2025 -

San Franciscos Anchor Brewing Company Announces Closure

Apr 22, 2025

San Franciscos Anchor Brewing Company Announces Closure

Apr 22, 2025 -

Aramco And Byd Join Forces To Explore Electric Vehicle Innovations

Apr 22, 2025

Aramco And Byd Join Forces To Explore Electric Vehicle Innovations

Apr 22, 2025 -

White House Cocaine Secret Service Concludes Investigation

Apr 22, 2025

White House Cocaine Secret Service Concludes Investigation

Apr 22, 2025