US Army's Right-to-Repair Policy: Challenges And Opportunities

Table of Contents

Challenges of Implementing a Right-to-Repair Policy in the US Army

Implementing a right-to-repair policy within the US Army presents a complex array of challenges that demand careful consideration. These challenges span national security, logistical complexities, and significant cost implications.

National Security Concerns

Granting broader access to repair military equipment introduces significant national security risks.

- Unauthorized Access to Sensitive Technology: Third-party repair access could compromise sensitive military technology, potentially leading to its unauthorized replication or dissemination to adversaries. This risk is amplified with advanced technologies like AI-integrated systems and sophisticated weaponry.

- Maintaining Repair Quality and Adherence to Military Specifications: Ensuring that repairs meet stringent military specifications outside of authorized channels is extremely challenging. Substandard repairs could lead to equipment malfunction, jeopardizing mission success and potentially endangering soldiers' lives.

- Counterfeit Parts and Equipment Reliability: The potential for counterfeit parts poses a severe threat. Using counterfeit parts can compromise equipment reliability, potentially causing catastrophic failures during critical operations. The consequences of such failures can range from mission delays to severe injuries or fatalities.

The potential consequences of compromised equipment are far-reaching. For instance, a failure in a critical communication system during a combat operation could severely hinder coordination and lead to significant losses. Similarly, a malfunctioning piece of artillery could result in unintended casualties. These scenarios highlight the importance of maintaining strict control over the repair and maintenance of military equipment.

Logistical Hurdles

The US Army's vast and geographically dispersed operational footprint significantly complicates the logistics of a right-to-repair initiative.

- Distribution of Repair Parts and Tools: Effectively distributing necessary repair parts and specialized tools to diverse locations, including remote and combat zones, poses a massive logistical challenge. This requires a robust and resilient supply chain.

- Soldier and Civilian Personnel Training: Training soldiers and civilian personnel on complex repair procedures necessitates substantial resources, including dedicated training programs, instructional materials, and experienced instructors.

- Supply Chain Management for Repair Parts: Effectively managing the supply chain for repair parts and tools is a complex undertaking. Maintaining sufficient stock levels, while avoiding obsolescence and waste, requires sophisticated inventory management and forecasting techniques. This includes considering the lifecycle of equipment and parts.

The complexities of managing a global supply chain for military equipment repairs are immense. Factors such as transportation costs, customs regulations, and security protocols all contribute to the logistical challenges. Moreover, training soldiers and civilian personnel on repair procedures can be expensive and time-consuming.

Cost Implications

The financial implications of a right-to-repair policy must be carefully analyzed, balancing potential cost savings with potential risks.

- Balancing Cost Savings with Security and Logistical Challenges: While a right-to-repair policy could potentially reduce repair costs, these savings must be weighed against the increased costs associated with ensuring national security and managing the logistical complexities.

- Costs Associated with Training, Tools, and Quality Control: Providing adequate training, tools, and quality control mechanisms for independent repairs adds significant costs. These costs need to be carefully budgeted and factored into the overall cost-benefit analysis.

- Financial Impact of Equipment Failure Due to Improper Repairs: The financial consequences of equipment failures resulting from improper repairs can be substantial, potentially exceeding the cost savings from alternative repair options.

A comprehensive cost-benefit analysis is necessary to determine the overall economic impact of a right-to-repair policy. This analysis should consider both short-term and long-term financial implications, including the potential costs associated with equipment failures and the potential savings from lower repair costs.

Opportunities Presented by a Well-Defined Right-to-Repair Policy

Despite the challenges, a well-structured right-to-repair policy for the US Army also presents significant opportunities.

Increased Operational Readiness

A streamlined repair process can dramatically enhance operational readiness.

- Faster Repair Turnaround Times: Faster repairs translate directly to reduced equipment downtime and increased equipment availability, leading to higher operational readiness.

- Improved Responsiveness in Remote or Conflict Zones: Reduced reliance on centralized repair facilities increases responsiveness in remote or conflict zones, where timely repairs are critical.

- Increased Efficiency and Reduced Maintenance Costs: Streamlined repair processes can lead to increased efficiency and reduced overall maintenance costs in the long run.

Faster repair times can significantly impact military readiness and responsiveness. For example, quicker repair of communication systems can improve situational awareness and coordination during operations. Similarly, faster repairs of vehicles and other equipment can ensure operational continuity in challenging environments.

Cost Savings

A right-to-repair policy has the potential to generate significant cost savings.

- Lower Repair Costs Through Alternative Repair Providers: Competition among repair providers can drive down repair costs compared to relying solely on original equipment manufacturers (OEMs).

- Reduced Reliance on Expensive OEM Parts: The use of alternative parts, where appropriate, can significantly reduce repair costs, particularly for commonly used components.

- Potential for Innovative Repair Solutions: A more competitive repair market can foster innovation, leading to the development of more cost-effective and efficient repair techniques.

The potential cost savings can be substantial. By utilizing alternative repair providers and parts, the Army can significantly reduce its maintenance budget. Innovation in repair solutions can further enhance cost savings and improve operational efficiency.

Enhanced Technological Innovation

A right-to-repair initiative can stimulate innovation within the military repair sector.

- Stimulating Development of New Tools, Techniques, and Technologies: Increased access to equipment and the need for efficient repair methods can stimulate the development of new repair tools, techniques, and technologies.

- Promoting Collaboration Between Military, Private Sector, and Academia: A right-to-repair policy can foster collaboration between the military, private sector companies, and academic institutions, leading to the development of innovative repair solutions.

- Fostering a More Robust and Resilient Repair Ecosystem: A more open repair ecosystem encourages competition and innovation, making the overall system more robust and resilient.

Encouraging innovation in the military repair sector can lead to significant improvements in equipment maintainability and reliability. Collaboration between different stakeholders can accelerate the development and adoption of new repair technologies.

Conclusion

The implementation of a US Army's right-to-repair policy necessitates a careful balancing act between national security imperatives, logistical considerations, and budgetary constraints. While concerns about national security and logistical challenges are valid and require robust mitigation strategies, the potential benefits – encompassing heightened operational readiness, substantial cost savings, and accelerated technological innovation – are compelling. A thoughtfully designed and meticulously executed right-to-repair policy, incorporating stringent security protocols and rigorous quality control measures, is essential for successfully navigating the inherent complexities and maximizing the significant opportunities. Further investigation and open dialogue surrounding the US Army's right-to-repair policy are crucial for ensuring the Army's continued readiness and effectiveness in the future. The future of military maintenance hinges on developing a comprehensive and secure US Army's right-to-repair policy.

Featured Posts

-

Cnn Releases Video Of New Orleans Jail Escape

May 18, 2025

Cnn Releases Video Of New Orleans Jail Escape

May 18, 2025 -

Mlb Betting Home Run Props And Predictions For May 8th Schwarber Focus

May 18, 2025

Mlb Betting Home Run Props And Predictions For May 8th Schwarber Focus

May 18, 2025 -

Cassie And Alex Fine A Red Carpet Moment During Cassies Pregnancy

May 18, 2025

Cassie And Alex Fine A Red Carpet Moment During Cassies Pregnancy

May 18, 2025 -

Jersey Mikes Subs Galesburg Location Details Revealed

May 18, 2025

Jersey Mikes Subs Galesburg Location Details Revealed

May 18, 2025 -

Maneskins Damiano David Rocks Jimmy Kimmel Live Alt 104 5

May 18, 2025

Maneskins Damiano David Rocks Jimmy Kimmel Live Alt 104 5

May 18, 2025

Latest Posts

-

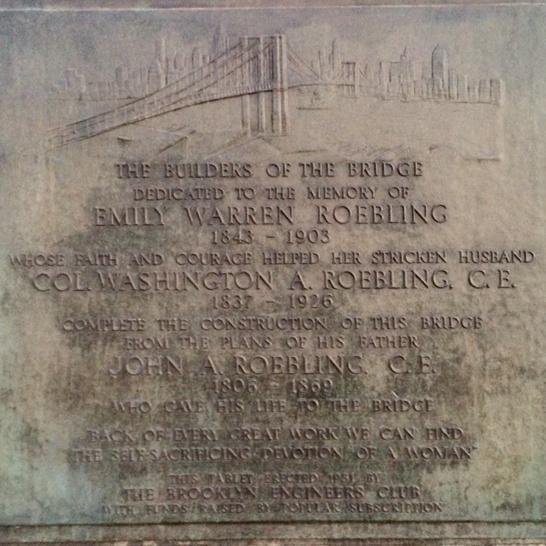

Emily Warren Roebling And The Brooklyn Bridge A Story Of Resilience And Achievement

May 18, 2025

Emily Warren Roebling And The Brooklyn Bridge A Story Of Resilience And Achievement

May 18, 2025 -

The Unsung Heroine Of The Brooklyn Bridge Remembering Emily Warren Roebling

May 18, 2025

The Unsung Heroine Of The Brooklyn Bridge Remembering Emily Warren Roebling

May 18, 2025 -

Emily Warren Roeblings Enduring Legacy The Brooklyn Bridge And Beyond

May 18, 2025

Emily Warren Roeblings Enduring Legacy The Brooklyn Bridge And Beyond

May 18, 2025 -

Honoring Emily Warren Roebling Her Crucial Role In Building The Brooklyn Bridge

May 18, 2025

Honoring Emily Warren Roebling Her Crucial Role In Building The Brooklyn Bridge

May 18, 2025 -

Bowen Yang Reacts Snls White Lotus Parody With Aimee Lou Wood

May 18, 2025

Bowen Yang Reacts Snls White Lotus Parody With Aimee Lou Wood

May 18, 2025