UPS And Figure AI: Humanoid Robots In Logistics?

Table of Contents

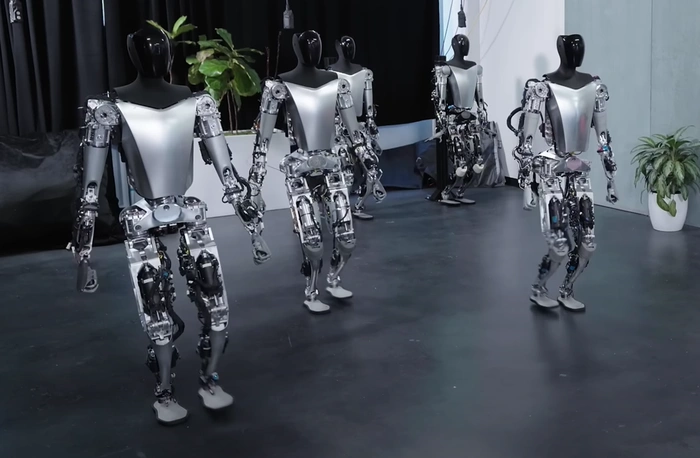

Figure AI's Humanoid Robots: Capabilities and Potential in Logistics

Figure AI is at the forefront of humanoid robotics, developing advanced robots with impressive capabilities that hold significant potential for the logistics industry.

Physical Capabilities:

Figure AI's robots boast remarkable physical capabilities, surpassing the limitations of traditional automated systems. Their design emphasizes:

- Dexterous Manipulation: These robots possess advanced hand-eye coordination and dexterity, allowing them to handle a wide variety of packages with precision. This dexterous manipulation is crucial for tasks requiring fine motor skills, unlike many existing warehouse robots.

- High Payload Capacity: With a substantial payload capacity, these robots can lift and carry heavy packages, reducing the strain on human workers and increasing efficiency in handling heavier goods.

- Exceptional Endurance and Mobility: Designed for endurance, these robots can operate for extended periods without needing frequent recharging or breaks. Their superior mobility allows them to navigate complex warehouse environments with ease.

- Task Examples: Specific tasks these robots could perform include lifting and placing packages onto conveyor belts, loading and unloading trucks, picking and packing orders, and even assisting with last-mile delivery in controlled environments.

Technological Advancements:

The intelligence behind Figure AI's robots is equally impressive. Their advanced systems include:

- Computer Vision: Sophisticated computer vision systems allow the robots to perceive their environment accurately, identify obstacles, and navigate safely.

- AI-Powered Navigation: AI-powered navigation ensures efficient and optimized movement within the warehouse, minimizing travel time and maximizing productivity.

- Object Recognition: Precise object recognition capabilities enable the robots to identify and handle different types of packages accurately, reducing errors and improving order fulfillment.

- Autonomous Operation: These robots are designed for autonomous operation, minimizing the need for constant human supervision, although human oversight remains essential for safety.

Potential for Increased Efficiency and Productivity:

The integration of Figure AI robots promises significant improvements in logistics efficiency:

- Faster Order Fulfillment: Automated processes will dramatically speed up order fulfillment, reducing processing times and improving customer satisfaction.

- Improved Accuracy in Warehouse Operations: The robots' precision and advanced systems will minimize errors in picking, packing, and sorting, reducing waste and increasing accuracy.

- Enhanced Last-Mile Delivery: In specific scenarios, these robots could assist with last-mile delivery, enhancing efficiency and potentially reducing delivery times.

- Supply Chain Optimization: By automating various processes, the robots contribute to supply chain optimization, streamlining operations and reducing costs. The potential cost savings associated with reduced labor costs and improved efficiency are substantial.

Challenges and Considerations of Implementing Humanoid Robots in Logistics

While the potential benefits are significant, several challenges and considerations must be addressed before widespread adoption:

Cost of Implementation:

- High Initial Investment: The robotics implementation cost is substantial, representing a significant automation investment for logistics companies.

- Return on Investment (ROI): A thorough analysis of ROI is crucial to determine the long-term financial viability of integrating these robots.

- Infrastructure Modifications: Existing warehouses might require modifications to accommodate the robots, adding further to the overall cost.

Safety and Security Concerns:

- Workplace Safety: Ensuring workplace safety is paramount. Robust robot safety protocols and collision avoidance systems are essential to prevent accidents in fast-paced environments.

- Human-Robot Collaboration: Effective human-robot collaboration strategies and training protocols are crucial to ensure safety and prevent incidents.

Ethical and Social Implications:

- Job Displacement: The potential for job displacement needs careful consideration. Proactive measures, such as reskilling and upskilling programs, are essential to mitigate the impact on human workers.

- Automation Ethics: Addressing the automation ethics surrounding widespread adoption of robots in the workforce is crucial.

UPS's Logistics Operations and Potential Integration of Figure AI Robots

UPS, a global leader in logistics, already utilizes significant automation in its operations. Let's explore how Figure AI robots could further enhance their capabilities:

Current UPS Infrastructure and Automation:

UPS currently employs various automated systems in its warehouses and delivery networks. Humanoid robots could complement these systems, particularly in areas such as:

- Package sorting: Handling a wider variety of package shapes and sizes more efficiently.

- Delivery assistance: Assisting with last-mile delivery in controlled environments.

Potential Scenarios for Collaboration:

Several potential scenarios exist for integrating Figure AI robots into UPS operations:

- Pilot programs: Testing the robots in specific warehouses or regions to assess their performance and identify areas for improvement.

- Phased rollout: Gradually expanding the use of robots across different parts of the UPS network.

- Strategic partnerships: Collaborating with Figure AI to develop customized solutions tailored to UPS's specific needs.

Long-Term Vision and Predictions:

In the long term, humanoid robots could transform UPS's logistics strategy, leading to:

- Increased efficiency and productivity throughout the entire supply chain.

- Enhanced customer satisfaction through faster and more reliable deliveries.

- A more resilient and adaptable logistics network capable of handling fluctuations in demand.

Conclusion: The Future of Logistics with UPS and Humanoid Robots

The integration of humanoid robots, such as those developed by Figure AI, into the logistics operations of companies like UPS holds immense potential. While challenges related to cost, safety, and ethical considerations exist, the potential benefits—increased efficiency, productivity, and cost savings—are significant. The future of logistics is likely to involve a dynamic collaboration between humans and robots, optimizing operations and revolutionizing the industry. To learn more about the advancements in humanoid robotics in logistics, the future of logistics automation, Figure AI robotics, and UPS innovation, we encourage you to explore further resources on this exciting field. The question "UPS and Figure AI: Humanoid Robots in Logistics?" is not just a question anymore, but rather a glimpse into the future.

Featured Posts

-

Michael Sheen And Channel 4s Debt Documentary A Copyright Lawsuit

May 01, 2025

Michael Sheen And Channel 4s Debt Documentary A Copyright Lawsuit

May 01, 2025 -

Cty Tam Hop Chien Thang Thuyet Phuc Goi Thau Cap Nuoc Gia Dinh Truoc 6 Doi Thu Khac

May 01, 2025

Cty Tam Hop Chien Thang Thuyet Phuc Goi Thau Cap Nuoc Gia Dinh Truoc 6 Doi Thu Khac

May 01, 2025 -

Two Bartlett Texas Structures Destroyed In Fire Total Loss Amid Red Flag Warning

May 01, 2025

Two Bartlett Texas Structures Destroyed In Fire Total Loss Amid Red Flag Warning

May 01, 2025 -

Rugby Match Report France Defeats Italy Duponts Stellar Display

May 01, 2025

Rugby Match Report France Defeats Italy Duponts Stellar Display

May 01, 2025 -

Enexis Wachtlijst Van Meer Dan 1000 Limburgse Ondernemers

May 01, 2025

Enexis Wachtlijst Van Meer Dan 1000 Limburgse Ondernemers

May 01, 2025

Latest Posts

-

Buzelio Tylejimas Po Savo Vardo Turnyro Vilniuje Kas Nutiko

May 01, 2025

Buzelio Tylejimas Po Savo Vardo Turnyro Vilniuje Kas Nutiko

May 01, 2025 -

Matas Buzelis Tyla Po Savo Vardo Turnyro Vilniuje

May 01, 2025

Matas Buzelis Tyla Po Savo Vardo Turnyro Vilniuje

May 01, 2025 -

L Impact Des Celebrations Avec Armes A Feu Sur La Carriere D Une Star Nba Et Sa Famille

May 01, 2025

L Impact Des Celebrations Avec Armes A Feu Sur La Carriere D Une Star Nba Et Sa Famille

May 01, 2025 -

Une Legende Du Basket Denonce Les Celebrations A L Arme A Feu D Une Star Nba

May 01, 2025

Une Legende Du Basket Denonce Les Celebrations A L Arme A Feu D Une Star Nba

May 01, 2025 -

Lidin I Bonusdeildinni Meistaradeildar Og Nba Leikjadagskra

May 01, 2025

Lidin I Bonusdeildinni Meistaradeildar Og Nba Leikjadagskra

May 01, 2025