The Impact Of Tariff Uncertainty: U.S. Companies' Cost-Cutting Strategies

Table of Contents

Restructuring Supply Chains: Diversification and Nearshoring/Onshoring

Faced with the instability of international trade relations, many U.S. companies are actively diversifying their supply chains. Over-reliance on single-source suppliers, particularly those located in countries imposing tariffs, has proven to be a risky strategy. The increased import costs associated with tariff uncertainty have accelerated the trend towards geographical diversification, spreading sourcing across multiple countries to reduce dependence on any single nation. This strategy, while offering resilience against trade disruptions, also presents considerable challenges.

The growing popularity of nearshoring and onshoring is another key response to tariff uncertainty. Relocating manufacturing facilities closer to home, or even within the same country, mitigates the risks associated with long and vulnerable supply chains. This strategy reduces transportation costs and lead times, while also improving responsiveness to market changes. However, nearshoring and onshoring often come with higher labor costs compared to offshore manufacturing.

- Increased transportation costs with diversified sourcing: Shipping goods from multiple locations naturally increases logistics expenses.

- Higher labor costs in nearshore/onshore locations: Domestic labor is typically more expensive than labor in many developing countries.

- Improved supply chain agility and resilience: Diversification and nearshoring offer greater flexibility to respond to disruptions.

- Potential loss of economies of scale: Spreading production across multiple smaller facilities can reduce efficiency gains.

Optimizing Production Processes: Automation and Efficiency Improvements

To counter the increased costs stemming from tariff uncertainty, many companies are investing heavily in automation and technological advancements. Lean manufacturing techniques, focused on minimizing waste and maximizing output, are becoming increasingly prevalent. Automation plays a vital role in reducing labor costs, improving productivity, and enhancing overall efficiency. The adoption of robotics, advanced analytics, and AI-powered systems allows for higher output with fewer human resources.

This shift towards automation, while offering significant cost savings in the long run, also necessitates careful consideration of its impact on employment. Job displacement due to automation is a concern, highlighting the need for retraining programs and investment in upskilling the workforce to meet the demands of a more technologically advanced manufacturing sector.

- Implementation costs of automation technology: The initial investment in automation equipment and software can be substantial.

- Potential job displacement due to automation: Automation can reduce the demand for certain types of labor.

- Long-term cost savings through increased efficiency: Automation leads to higher productivity and lower labor costs over time.

- Improved product quality and consistency: Automation minimizes human error, resulting in higher quality products.

Negotiating with Suppliers: Price Reductions and Contract Renegotiations

Effective negotiation with suppliers is crucial for businesses grappling with the impact of tariff uncertainty. Companies are actively seeking price reductions from their suppliers to offset the increased import costs resulting from tariffs. Maintaining strong supplier relationships is vital during this process. Open communication, trust, and collaboration are key to negotiating favorable terms and mitigating the negative impacts of trade disputes.

However, negotiating during periods of trade uncertainty poses significant challenges. Suppliers may be reluctant to reduce prices, particularly if they are also facing increased input costs. This necessitates a delicate balancing act between securing cost savings and preserving essential supplier relationships.

- Risk of strained supplier relationships: Aggressive price negotiations can damage long-term partnerships.

- Potential for reduced supplier quality to achieve lower prices: Pressure to reduce prices might compromise supplier quality.

- Successful negotiation resulting in cost savings: Strategic negotiation can significantly mitigate tariff-related cost increases.

- The need for transparent communication and trust: Open dialogue and mutual understanding are essential for successful negotiations.

Pricing Strategies: Passing Costs to Consumers and Absorbing Losses

One of the most challenging decisions for businesses facing tariff uncertainty is how to manage increased costs. Companies must determine whether to pass these increased costs onto consumers through higher prices or absorb them, impacting their profitability. Passing on increased costs can lead to a loss of market share if competitors are able to maintain lower prices. Absorbing the costs, on the other hand, can severely impact profitability and long-term sustainability, especially in a competitive market environment. Inflation further complicates this decision, making precise market analysis crucial.

- Potential loss of market share by raising prices: Price increases can make products less competitive.

- Reduced profitability by absorbing cost increases: Absorbing costs reduces profit margins, impacting long-term viability.

- The impact of inflation on pricing strategies: Inflation makes cost management and pricing decisions even more complex.

- The need for careful market analysis before price adjustments: Understanding consumer sensitivity to price changes is vital.

Mitigating the Impact of Tariff Uncertainty: A Proactive Approach

In conclusion, U.S. companies are employing a range of cost-cutting strategies to mitigate the effects of tariff uncertainty. Restructuring supply chains, optimizing production processes, negotiating effectively with suppliers, and carefully managing pricing strategies are all vital components of a proactive approach. Navigating this environment requires careful planning, adaptation, and a willingness to embrace innovative solutions. The long-term implications of tariff uncertainty on business strategies and economic growth are significant, demanding a robust and flexible approach to risk management.

To effectively mitigate the impact of tariff uncertainty on your business, develop a proactive strategy that incorporates supply chain diversification, process optimization, and flexible pricing models. Explore resources on supply chain management and risk mitigation to further enhance your understanding and preparedness for fluctuating trade policies. Don't wait for the next trade disruption; prepare now to navigate the challenges of tariff uncertainty and ensure your business's long-term success.

Featured Posts

-

Chinas Impact On Luxury Car Sales Bmw Porsche And Beyond

Apr 29, 2025

Chinas Impact On Luxury Car Sales Bmw Porsche And Beyond

Apr 29, 2025 -

Nbas 50 000 Fine Anthony Edwards And The Fan Incident

Apr 29, 2025

Nbas 50 000 Fine Anthony Edwards And The Fan Incident

Apr 29, 2025 -

The Evolving Chinese Automotive Landscape A Look At Bmw Porsche And The Future

Apr 29, 2025

The Evolving Chinese Automotive Landscape A Look At Bmw Porsche And The Future

Apr 29, 2025 -

New Report Details The Horrors Of The D C Blackhawk Passenger Jet Crash

Apr 29, 2025

New Report Details The Horrors Of The D C Blackhawk Passenger Jet Crash

Apr 29, 2025 -

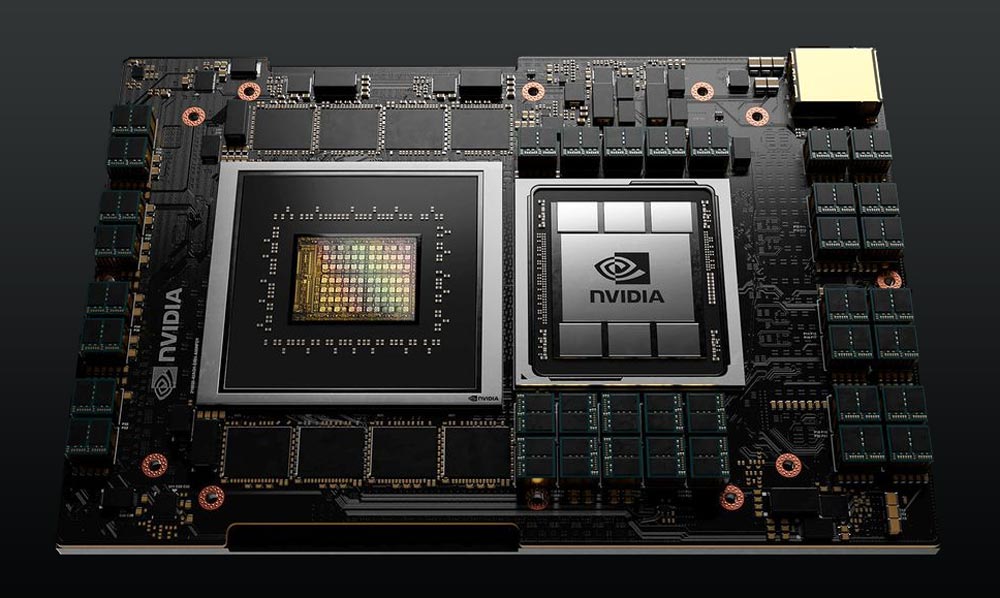

Chinas Huawei Unveils New Ai Chip Technology Closing The Gap On Nvidia

Apr 29, 2025

Chinas Huawei Unveils New Ai Chip Technology Closing The Gap On Nvidia

Apr 29, 2025

Latest Posts

-

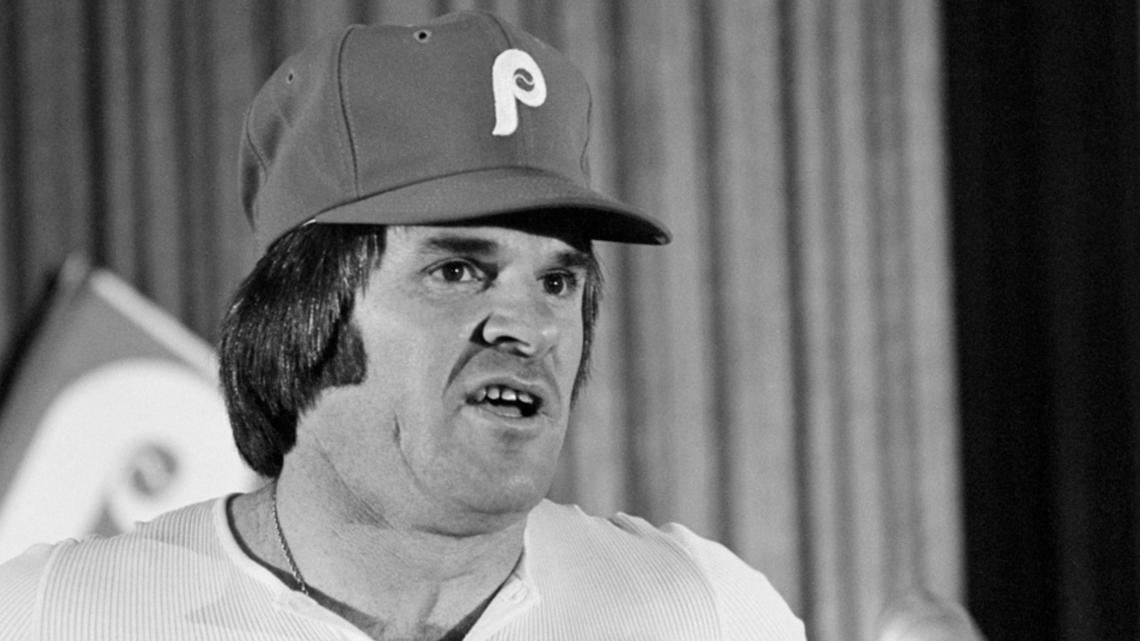

Pete Rose Pardon Trumps Plan And Its Implications For Baseball

Apr 29, 2025

Pete Rose Pardon Trumps Plan And Its Implications For Baseball

Apr 29, 2025 -

Donald Trump Calls For Pete Rose Pardon And Hall Of Fame Induction

Apr 29, 2025

Donald Trump Calls For Pete Rose Pardon And Hall Of Fame Induction

Apr 29, 2025 -

The Pete Rose Pardon Donald Trumps Presidential Gamble

Apr 29, 2025

The Pete Rose Pardon Donald Trumps Presidential Gamble

Apr 29, 2025 -

Will Trump Pardon Pete Rose The Impact On Baseball And Sports Betting

Apr 29, 2025

Will Trump Pardon Pete Rose The Impact On Baseball And Sports Betting

Apr 29, 2025 -

Trump Promises Pete Rose A Posthumous Pardon Following Mlb Criticism

Apr 29, 2025

Trump Promises Pete Rose A Posthumous Pardon Following Mlb Criticism

Apr 29, 2025