The Complexities Of All-American Manufacturing

Table of Contents

H2: The High Cost of Domestic Production

The allure of "Made in the USA" is undeniable, yet the reality is that domestic production often faces significant cost hurdles compared to overseas manufacturing. These increased costs stem from various factors, impacting the competitiveness of All-American goods in the global market.

H3: Labor Costs

American workers command higher wages and benefit packages than their counterparts in many other countries. This translates directly to higher production costs.

- Impact on pricing competitiveness: Higher labor costs often lead to higher prices, potentially making All-American products less competitive against cheaper imports.

- Automation as a solution: To mitigate the impact of high labor costs, many manufacturers are investing heavily in automation and robotics to increase efficiency and reduce reliance on manual labor. This shift requires significant upfront investment but can lead to long-term cost savings.

- The skilled labor shortage: Finding and retaining skilled workers remains a persistent challenge. The lack of a robust pipeline of skilled labor adds another layer of complexity and cost to All-American manufacturing. Statistics show a significant skills gap in key manufacturing sectors, leading to increased competition for talent and higher wages. For example, according to [insert reputable source and statistic here], the manufacturing sector is facing a shortage of [insert number] skilled workers.

H3: Raw Material Sourcing

Sourcing raw materials domestically presents its own set of challenges.

- Transportation costs: The cost of transporting raw materials across vast distances within the US can significantly increase production costs.

- Reliance on foreign sources for certain materials: Despite efforts to bolster domestic sourcing, the US remains reliant on foreign suppliers for certain essential raw materials, making the manufacturing process vulnerable to global supply chain disruptions. This reliance necessitates careful risk management strategies and diversified sourcing to mitigate potential disruptions.

- Impact of environmental regulations: Stringent environmental regulations, while crucial for sustainability, can add to the overall cost of production, particularly for industries with significant environmental footprints.

H3: Regulatory Compliance

Navigating the complex web of US environmental, safety, and labor regulations adds another layer of cost and complexity to All-American manufacturing.

- Compliance costs: Meeting these regulations often entails significant investments in specialized equipment, training, and administrative processes.

- Administrative burden: The paperwork and administrative processes associated with regulatory compliance can be substantial, diverting resources away from core manufacturing activities.

- Potential for delays and penalties: Non-compliance can lead to costly delays, fines, and reputational damage. The complexities of navigating various federal, state, and local regulations can pose significant challenges for manufacturers.

H2: Maintaining Quality and Innovation in All-American Manufacturing

Despite the challenges, All-American manufacturing remains synonymous with high quality and continuous innovation. Maintaining this reputation requires a dedicated focus on several key areas.

H3: Quality Control

US manufacturers have a long-standing commitment to delivering high-quality products. This commitment is reflected in rigorous quality control processes.

- Quality control processes: Implementation of robust quality control processes, from raw material inspection to final product testing, is crucial to maintain high standards.

- Rigorous testing: Thorough testing at various stages of production ensures that only products meeting the highest quality standards reach the market.

- Consumer expectations: American consumers, known for their high standards, demand quality products, placing further emphasis on robust quality control measures.

H3: Technological Advancement

Staying competitive in the global market necessitates continuous investment in research and development.

- Automation, robotics, AI: The adoption of advanced technologies like automation, robotics, and artificial intelligence (AI) is critical for improving productivity, efficiency, and precision.

- Impact on productivity and efficiency: These technologies contribute significantly to increased productivity and efficiency, offsetting some of the higher labor costs.

- Innovative technologies: US manufacturers are at the forefront of developing and implementing innovative technologies, setting a high bar for global competitors. Examples include [insert specific examples of innovative technologies].

H3: Skilled Workforce Development

A skilled workforce is paramount to the success of advanced manufacturing techniques.

- Vocational training: Investment in vocational training programs is essential to cultivate a pipeline of skilled workers for the manufacturing sector.

- Apprenticeships: Apprenticeship programs provide valuable hands-on experience and training, bridging the gap between education and industry needs.

- STEM education initiatives: Encouraging STEM education (science, technology, engineering, and mathematics) from an early age is critical to ensuring a future supply of skilled workers. Addressing the skills gap requires a concerted effort across educational institutions, industry, and government. [Insert statistics on current skills gap and initiatives to address it].

H2: The Future of All-American Manufacturing: Opportunities and Strategies

Despite the challenges, the future of All-American manufacturing holds significant promise. Several key strategies are emerging to enhance its competitiveness and growth.

H3: Reshoring and Nearshoring

The trends of reshoring (bringing manufacturing back to the US) and nearshoring (moving manufacturing to nearby countries) are gaining momentum.

- Motivations for reshoring: Factors driving reshoring include rising transportation costs, concerns about supply chain reliability, and a desire to support domestic jobs.

- Benefits and challenges: Reshoring offers numerous benefits, including job creation and improved supply chain resilience. However, it also presents challenges, particularly related to cost competitiveness.

- Examples of companies reshoring operations: Several prominent companies have successfully reshored manufacturing operations, demonstrating the viability of this strategy. [Insert examples].

H3: Government Support and Incentives

Government policies play a vital role in supporting domestic manufacturing.

- Tax breaks, grants, subsidies: Government incentives such as tax breaks, grants, and subsidies can help offset the higher costs of domestic production.

- Trade policies: Strategic trade policies that promote fair competition and protect domestic industries are essential for the long-term health of All-American manufacturing.

- Specific government initiatives: Numerous government programs are designed to support domestic manufacturing, fostering innovation and job creation. [Insert examples].

H3: Focus on Niche Markets and Specialized Products

Concentrating on high-value, specialized products is a key strategy for offsetting higher production costs.

- Examples of successful niche markets: Focusing on niche markets allows manufacturers to leverage unique American expertise and command premium prices, mitigating the impact of higher production costs.

- Competitive advantages: Specialization allows manufacturers to develop competitive advantages based on quality, innovation, and specialized skills.

- Leveraging unique American expertise: The US possesses a strong foundation of engineering expertise and innovative capacity, which can be leveraged to produce high-value, specialized products.

3. Conclusion

The complexities of All-American manufacturing are undeniable. Balancing the pursuit of cost-effectiveness with the demands for quality and innovation within a globalized market requires a multifaceted approach. However, the opportunities are equally significant. Strategic investments in technology, workforce development, government support, and a focus on niche markets are key to ensuring the continued growth and competitiveness of All-American manufacturing. Support domestic production – choose products made with All-American manufacturing processes and contribute to a stronger, more resilient American economy. Learn more about the vital role of All-American manufacturing and discover the businesses committed to its success.

Featured Posts

-

New Business Hot Spots Across The Nation An Interactive Map

Apr 29, 2025

New Business Hot Spots Across The Nation An Interactive Map

Apr 29, 2025 -

Black Hawk Helicopter Crash Pilots Mistakes And The 67 Fatalities

Apr 29, 2025

Black Hawk Helicopter Crash Pilots Mistakes And The 67 Fatalities

Apr 29, 2025 -

Macario Martinezs Overnight Success A Street Sweepers Journey To Fame

Apr 29, 2025

Macario Martinezs Overnight Success A Street Sweepers Journey To Fame

Apr 29, 2025 -

Is Anthony Edwards Playing Tonight Timberwolves Vs Lakers Injury Report

Apr 29, 2025

Is Anthony Edwards Playing Tonight Timberwolves Vs Lakers Injury Report

Apr 29, 2025 -

Nyt Strands Hints And Answers Tuesday April 29 Game 422

Apr 29, 2025

Nyt Strands Hints And Answers Tuesday April 29 Game 422

Apr 29, 2025

Latest Posts

-

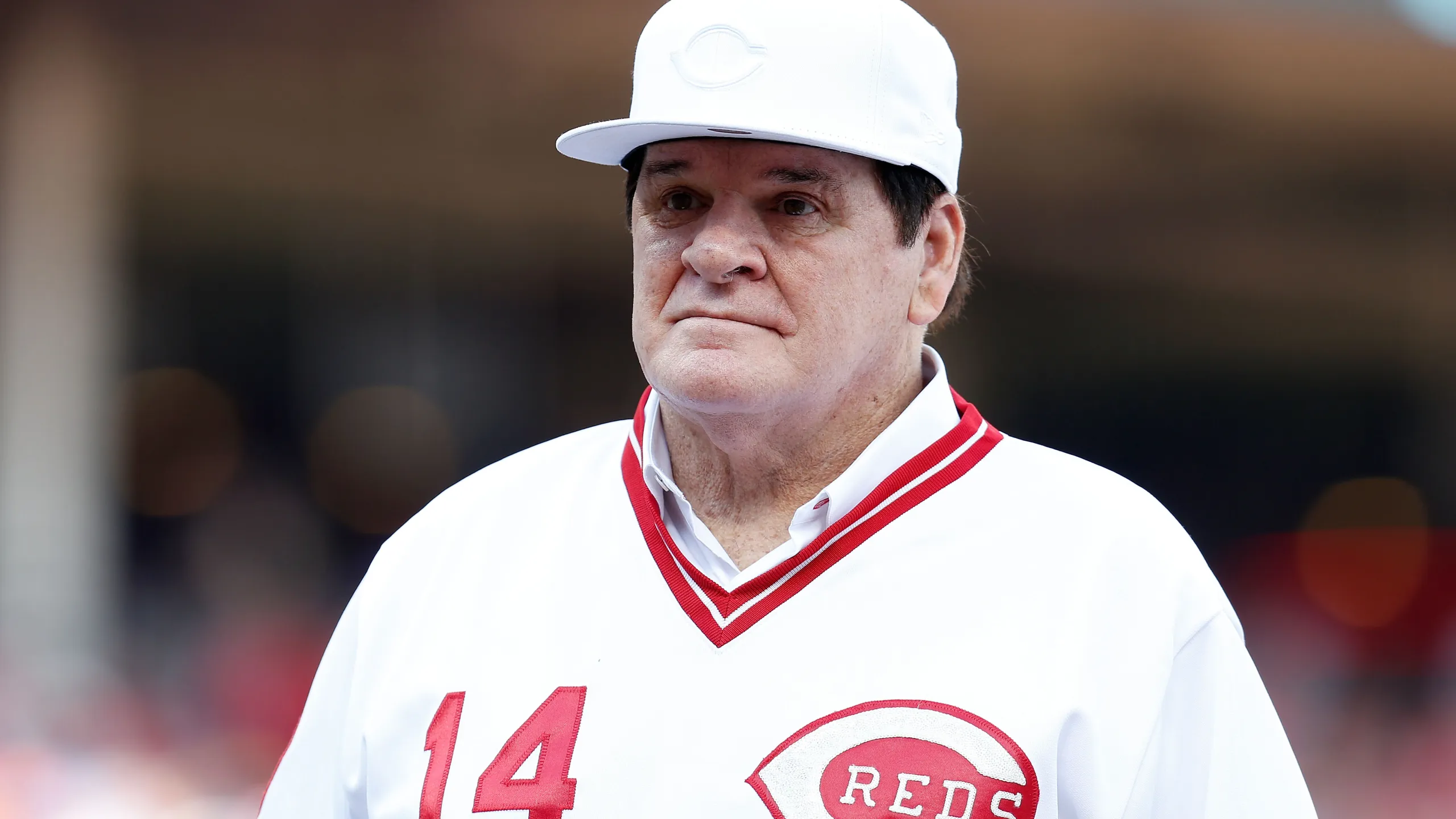

Donald Trump Calls For Pete Rose Pardon And Hall Of Fame Induction

Apr 29, 2025

Donald Trump Calls For Pete Rose Pardon And Hall Of Fame Induction

Apr 29, 2025 -

The Pete Rose Pardon Donald Trumps Presidential Gamble

Apr 29, 2025

The Pete Rose Pardon Donald Trumps Presidential Gamble

Apr 29, 2025 -

Will Trump Pardon Pete Rose The Impact On Baseball And Sports Betting

Apr 29, 2025

Will Trump Pardon Pete Rose The Impact On Baseball And Sports Betting

Apr 29, 2025 -

Trump Promises Pete Rose A Posthumous Pardon Following Mlb Criticism

Apr 29, 2025

Trump Promises Pete Rose A Posthumous Pardon Following Mlb Criticism

Apr 29, 2025 -

Trumps Potential Pardon Of Pete Rose A Look At The Mlb Betting Ban

Apr 29, 2025

Trumps Potential Pardon Of Pete Rose A Look At The Mlb Betting Ban

Apr 29, 2025