The Automotive Industry's Biggest Loser: How Trump's Tariffs Hit Toyota Hardest

Table of Contents

The Structure of Trump's Steel and Aluminum Tariffs: A Direct Hit on Toyota's Supply Chain

Trump's tariffs on imported steel and aluminum, implemented in 2018 under the guise of national security, directly targeted a critical component of Toyota's manufacturing process. This had a ripple effect throughout the company's operations.

Increased Raw Material Costs

The tariffs significantly increased the cost of steel and aluminum, vital raw materials for automotive production. This had several immediate consequences:

- Increased cost of parts: Higher raw material prices led to a substantial increase in the cost of producing numerous components, from body panels to engine blocks.

- Impact on vehicle pricing: Toyota faced the difficult choice of absorbing these increased costs, reducing profit margins, or passing them onto consumers through higher vehicle prices.

- Reduced profit margins: Even with price adjustments, the increased costs of raw materials squeezed Toyota's profit margins, impacting overall profitability.

- Effect on global competitiveness: The higher production costs made Toyota's vehicles less competitive in the global market compared to manufacturers in countries unaffected by the tariffs. This was particularly noticeable in models like the Camry and Tacoma, which rely heavily on US production.

Disruption of Global Supply Chains

Toyota's global supply chain, famed for its efficiency and just-in-time manufacturing, proved particularly vulnerable to the disruption caused by the tariffs.

- Suppliers affected: Many of Toyota's suppliers were impacted, either directly by the tariffs or indirectly through increased transportation costs and logistical hurdles.

- Logistical challenges: The tariffs created bottlenecks and delays in the supply chain, disrupting the carefully orchestrated flow of parts needed for assembly.

- Increased transportation costs: Companies sought alternative routes and suppliers, leading to higher transportation costs, adding to the overall production expenses.

- Vulnerability of just-in-time manufacturing: The just-in-time system, which minimizes inventory by delivering parts precisely when needed, became significantly riskier and less efficient due to the uncertainties introduced by the tariffs.

Retaliatory Tariffs from Trading Partners

The Trump tariffs weren't a one-way street. Retaliatory tariffs imposed by other countries on US goods further hampered Toyota's operations and sales.

- Reduced export market access: Tariffs on US-made vehicles in countries like China and the EU reduced Toyota's access to these important export markets.

- Impact on sales in specific countries: Sales of Toyota vehicles in countries that imposed retaliatory tariffs suffered declines, impacting revenue and market share.

- Increased competition from locally produced vehicles: The tariffs created a more favorable environment for locally produced vehicles in many markets, increasing the competitive pressure on Toyota.

Toyota's Response to Trump's Tariffs: Adaptation and Mitigation Strategies

Faced with this unprecedented challenge, Toyota implemented several strategies to mitigate the impact of Trump's tariffs.

Price Adjustments

Toyota, like other automakers, responded by adjusting vehicle prices to reflect the increased production costs.

- Magnitude of price increases: The price increases varied depending on the model and the extent to which it relied on tariff-affected components.

- Impact on consumer demand: Higher prices naturally impacted consumer demand, with some potential buyers delaying purchases or opting for less expensive alternatives.

- Strategies to maintain market share: Toyota employed various strategies to maintain market share, including targeted marketing campaigns and financing options to incentivize purchases.

Supply Chain Diversification

Recognizing the vulnerability of its supply chain, Toyota initiated efforts to diversify its sourcing of steel and aluminum.

- Shifting sourcing to other countries: The company sought out alternative suppliers in countries not subject to the tariffs, geographically diversifying its supply chain.

- Investment in domestic production: Toyota also considered increasing domestic production to reduce its reliance on imported materials, a long-term strategy to mitigate future trade risks.

- Long-term implications: This diversification effort represented a significant investment and a restructuring of its global operations with long-term implications for the company's manufacturing strategy.

Lobbying Efforts

Toyota, along with other automotive industry stakeholders, likely engaged in lobbying efforts to influence US trade policy.

- Engagement with government officials: The company likely engaged with government officials to advocate for tariff reductions or exemptions.

- Participation in trade organizations: Toyota likely participated in trade organizations and industry coalitions to exert collective pressure on policymakers.

- Advocacy for tariff reductions: The company's lobbying efforts likely focused on advocating for a more predictable and less protectionist trade environment.

Long-Term Implications for Toyota and the Broader Automotive Landscape

Trump's tariffs had lasting consequences, reshaping the global automotive landscape and impacting consumers.

Shift in Global Automotive Manufacturing

The tariffs accelerated a shift towards regionalization in automotive manufacturing.

- Restructuring of supply chains: Companies, including Toyota, restructured their global supply chains to reduce reliance on tariff-affected countries.

- Changes in investment strategies: Investment decisions shifted, with companies prioritizing locations offering greater stability and reduced trade risks.

- Increased regionalization of production: There was a discernible trend toward producing more vehicles closer to their target markets, reducing reliance on international trade.

Impact on Consumer Prices and Choice

Consumers ultimately bore some of the brunt of the tariffs.

- Increased vehicle prices: The increased production costs, passed on to consumers, led to higher vehicle prices across the board.

- Reduced consumer purchasing power: Higher prices reduced consumer purchasing power, affecting overall demand and potentially slowing market growth.

- Potential impact on the used car market: The changes in the new car market likely had indirect consequences on the used car market, including price fluctuations.

Conclusion: The Enduring Legacy of Trump's Tariffs on Toyota and the Automotive Sector

Trump's tariffs inflicted significant damage on Toyota, illustrating the far-reaching consequences of protectionist trade policies. The increased costs, supply chain disruptions, and long-term strategic adjustments highlight the vulnerability of even the most successful global companies to unpredictable trade wars. Toyota's experience serves as a powerful case study of how Trump tariffs and other protectionist measures can negatively impact the automotive industry and the broader global economy. Further investigation into the effects of trade policies on various industries, and a commitment to fair trade practices, is crucial for ensuring a stable and prosperous future for global commerce. Analyzing the impact of Trump tariffs on Toyota and other major players within the automotive industry is vital for informed policymaking and avoiding similar disruptions in the future.

Featured Posts

-

Aldo Returns To Featherweight A Look At His Comeback Chances

May 12, 2025

Aldo Returns To Featherweight A Look At His Comeback Chances

May 12, 2025 -

Manfreds Bristol Speedway Classic Fan Attendance Anticipation

May 12, 2025

Manfreds Bristol Speedway Classic Fan Attendance Anticipation

May 12, 2025 -

Nine Candidates One Papacy The Selection Process Explained

May 12, 2025

Nine Candidates One Papacy The Selection Process Explained

May 12, 2025 -

El Asilo De Martinelli En Colombia Implicaciones Politicas Regionales

May 12, 2025

El Asilo De Martinelli En Colombia Implicaciones Politicas Regionales

May 12, 2025 -

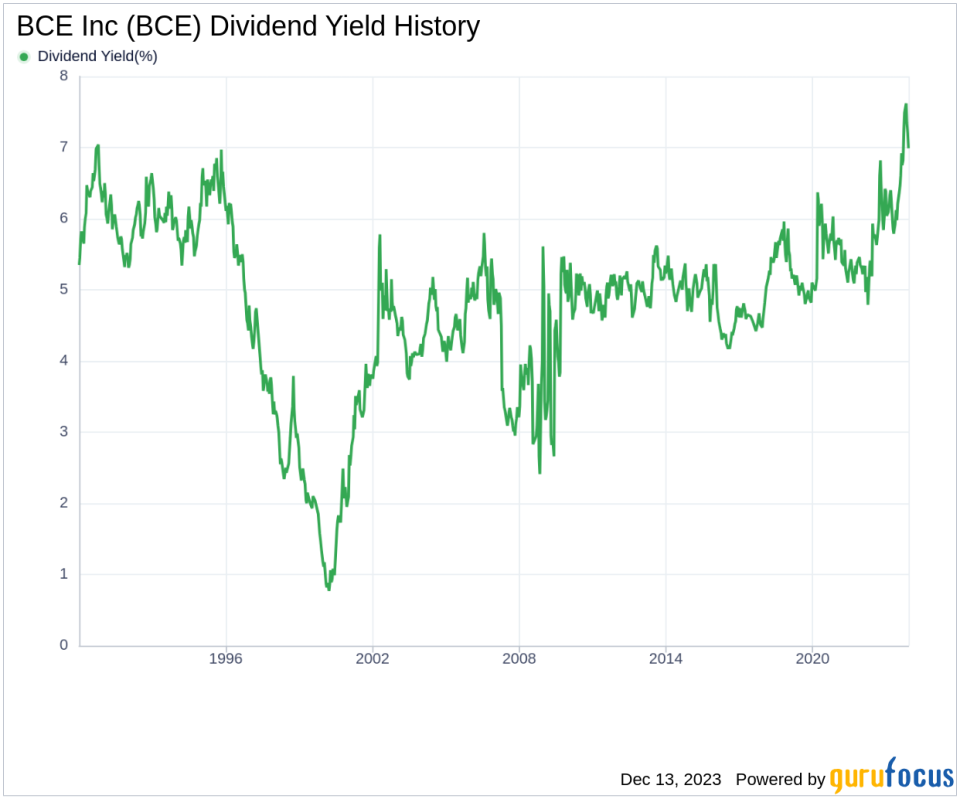

The Bce Inc Dividend Cut What It Means For Your Investment

May 12, 2025

The Bce Inc Dividend Cut What It Means For Your Investment

May 12, 2025

Latest Posts

-

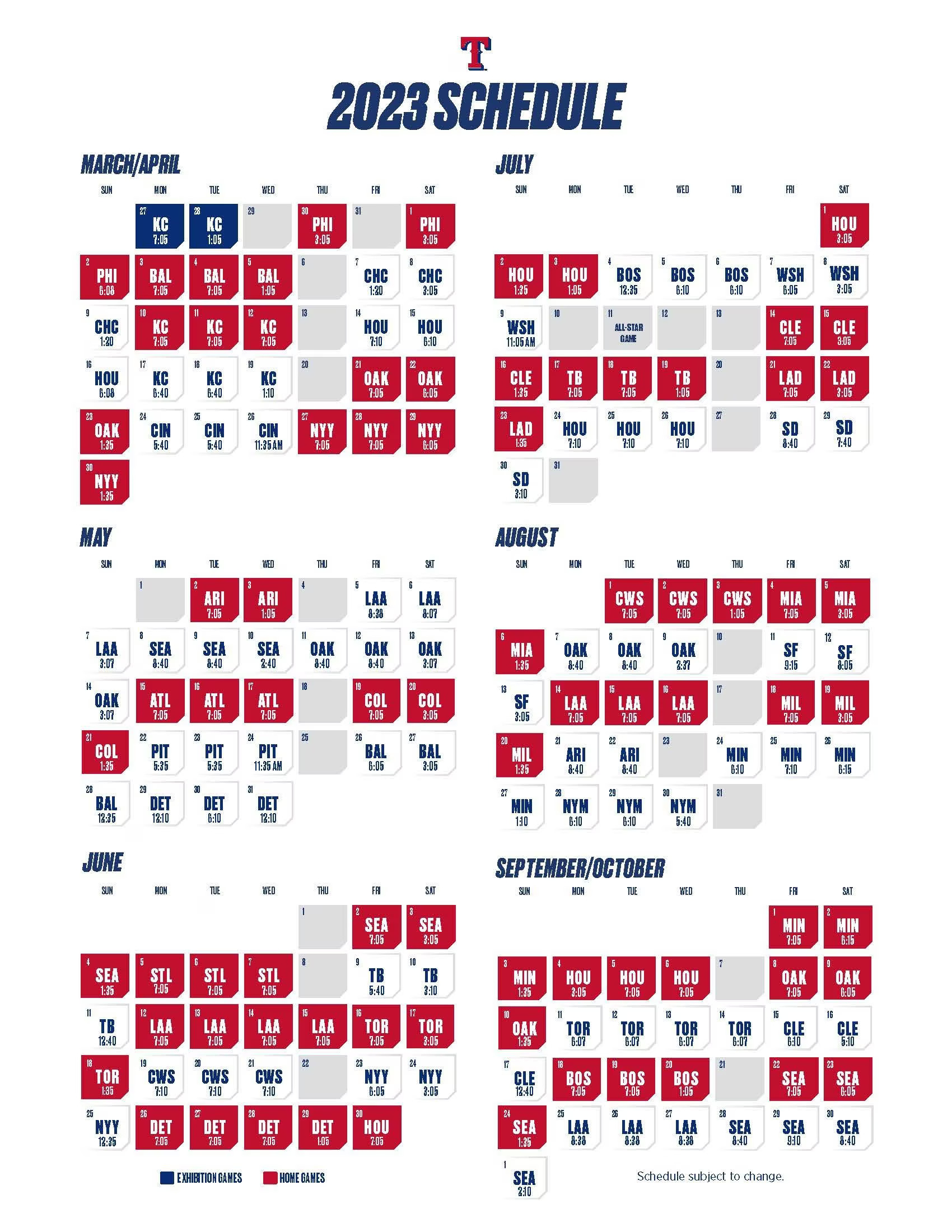

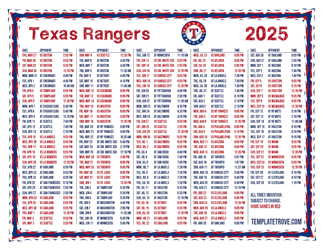

Watch Texas Rangers Vs Boston Red Sox Free Mlb Live Stream

May 13, 2025

Watch Texas Rangers Vs Boston Red Sox Free Mlb Live Stream

May 13, 2025 -

Texas Rangers 2025 Season Complete Guide To Watching Every Game

May 13, 2025

Texas Rangers 2025 Season Complete Guide To Watching Every Game

May 13, 2025 -

How To Watch Texas Rangers Games In 2025 Schedule Broadcast Info And Blackout Rules

May 13, 2025

How To Watch Texas Rangers Games In 2025 Schedule Broadcast Info And Blackout Rules

May 13, 2025 -

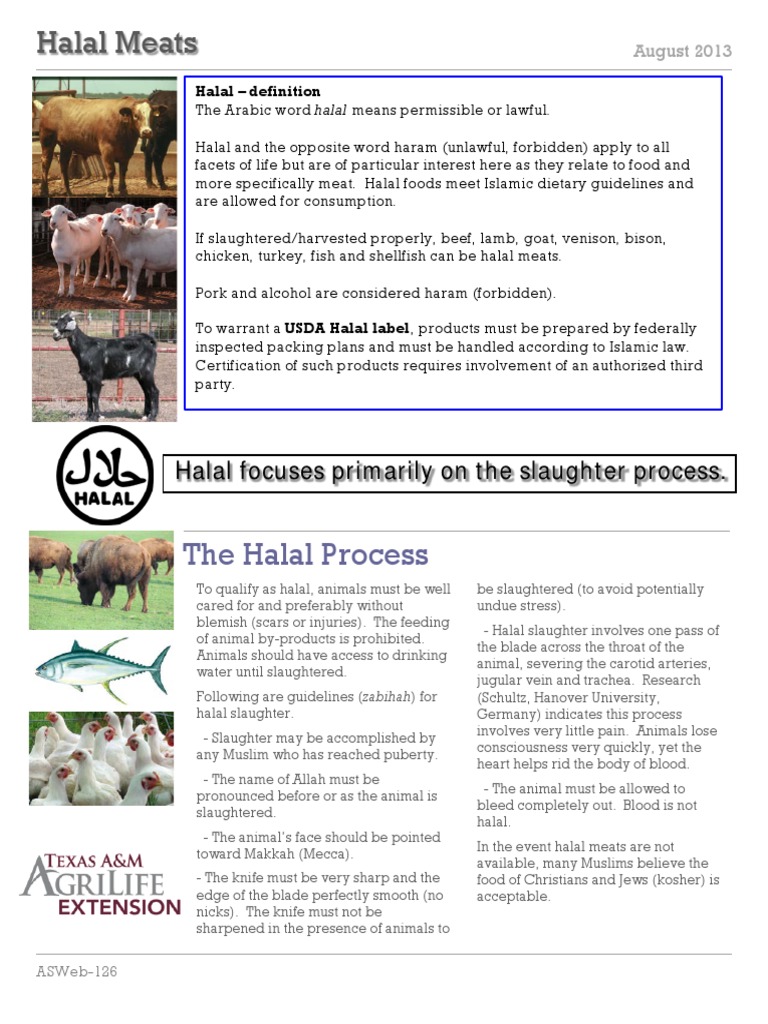

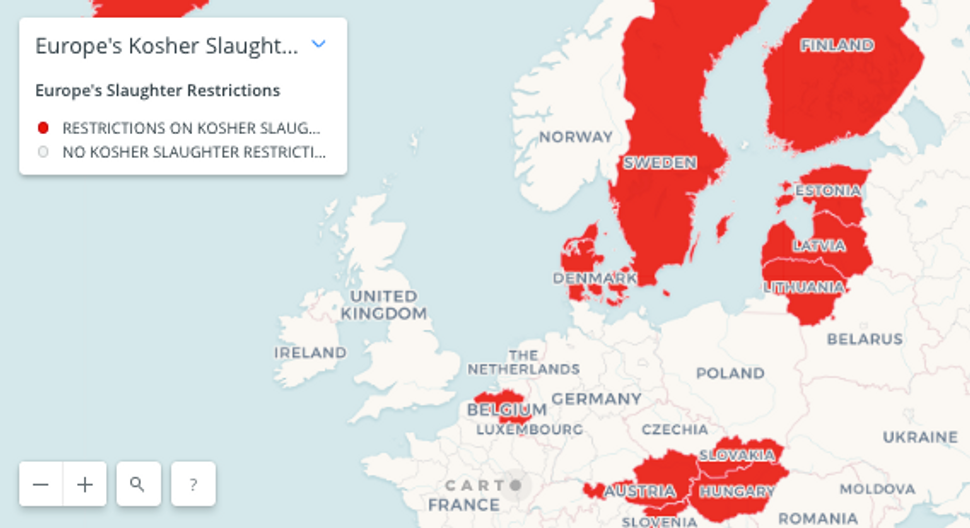

Addressing The Ethical Concerns Of Halal Slaughter For Vegans

May 13, 2025

Addressing The Ethical Concerns Of Halal Slaughter For Vegans

May 13, 2025 -

The Vegan Stance On Halal Meat Production Ethical Considerations

May 13, 2025

The Vegan Stance On Halal Meat Production Ethical Considerations

May 13, 2025