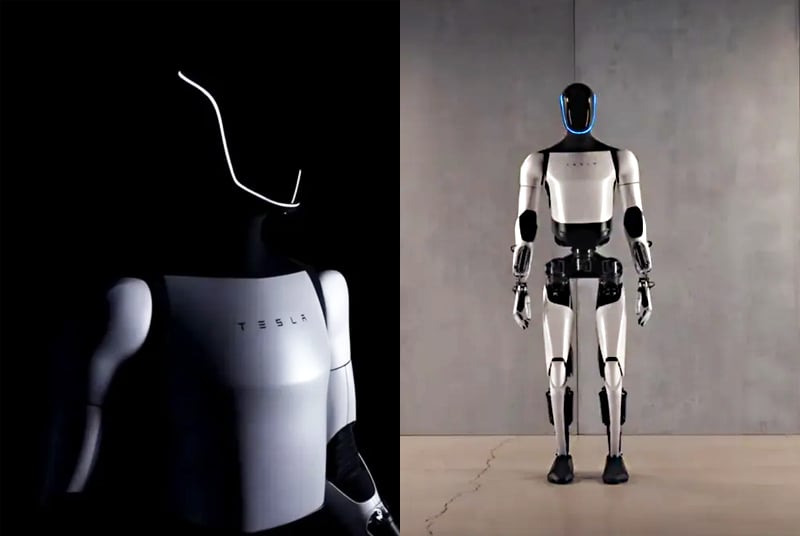

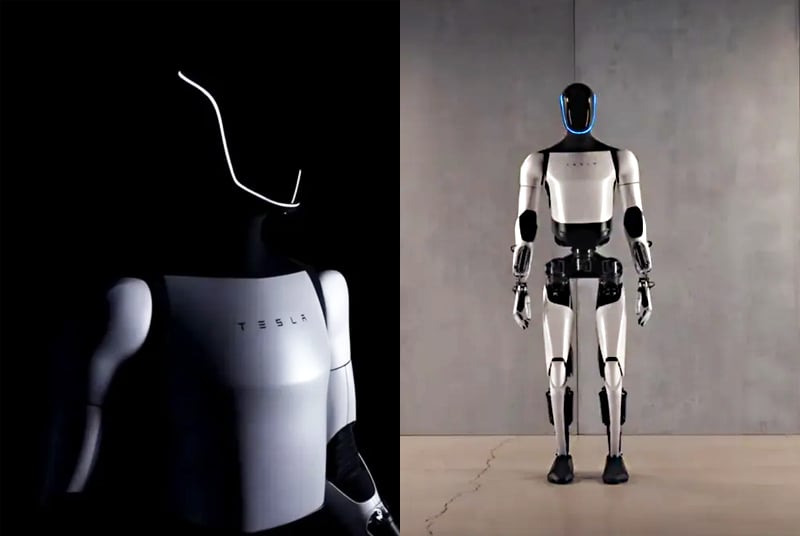

Tesla's Optimus Robot Development: Navigating The Complexities Of Rare Earth Supply Chains

Table of Contents

The Critical Role of Rare Earth Elements in Robotics

Rare earth elements (REEs) are indispensable for the high-performance capabilities of robots like Optimus. Their unique magnetic, electrical, and catalytic properties are unmatched by readily available alternatives.

Essential Rare Earth Metals in Optimus

Optimus's sophisticated motors, sensors, and other crucial components heavily rely on several key REEs:

- Neodymium (Nd): Used in powerful permanent magnets within the robot's motors, enabling precise and efficient movement. Neodymium magnets are essential for the robot's actuators and joint mechanisms.

- Dysprosium (Dy): Crucial for enhancing the temperature resistance and magnetic strength of neodymium magnets, ensuring optimal performance even under demanding conditions. Dysprosium's addition is vital for maintaining the robot's power and precision.

- Praseodymium (Pr): Often used in conjunction with neodymium in magnets, praseodymium improves their magnetic properties and thermal stability.

- Terbium (Tb): Used in certain sensors and actuators, contributing to their responsiveness and accuracy.

These elements' unique properties—high magnetic strength, low density, and corrosion resistance—are difficult to replicate, making them irreplaceable in many robotic applications.

The Technological Dependence on Rare Earths

Currently, there are no readily available and cost-effective substitutes for these REEs in high-performance robotics. While research into alternative materials is ongoing, significant technological hurdles remain:

- Challenges in achieving comparable magnetic strength and thermal stability.

- Difficulty in scaling up the production of alternative materials to meet industrial demand.

- Higher cost and lower efficiency compared to REEs.

Ongoing research explores alternative materials and designs, but the immediate future of advanced robotics, including Optimus, remains heavily dependent on REEs.

Navigating the Geopolitical Landscape of Rare Earth Mining and Processing

The global rare earth supply chain is characterized by significant geopolitical complexities, primarily due to the concentration of mining and processing activities.

China's Dominance in the Rare Earth Market

China holds a dominant position in the global rare earth market, controlling a significant portion of both mining and processing. This concentration creates potential risks:

- Market Share: China currently holds over 60% of the global rare earth production.

- Geopolitical Risks: Potential for trade disputes or export restrictions could severely disrupt the supply of crucial REEs to global manufacturers, including Tesla.

- Price Volatility: China's control can lead to price fluctuations, impacting the profitability and production timelines of robotics companies.

This dependence on a single major player presents a significant vulnerability for companies reliant on REEs, like Tesla.

Ethical and Environmental Concerns

The extraction and processing of rare earth elements raise significant ethical and environmental concerns:

- Water Pollution: Mining operations can contaminate water sources with heavy metals and radioactive materials.

- Habitat Destruction: Mining activities often lead to habitat loss and biodiversity decline.

- Worker Safety: Mining and processing can pose risks to worker health and safety.

The industry is increasingly focused on sustainable practices and ethical sourcing, with initiatives promoting responsible mining and recycling.

Tesla's Strategies for Mitigating Rare Earth Supply Chain Risks

Tesla is aware of the challenges posed by the rare earth supply chain and is actively pursuing strategies to mitigate these risks.

Diversification of Supply Sources

To reduce dependence on any single supplier, Tesla is actively diversifying its sourcing of REEs:

- Partnerships: Tesla is forging partnerships with mining companies in countries like Australia and the US.

- Investments: Investments in new mining projects outside of China aim to secure access to diverse sources of rare earth materials.

This diversification strategy helps to reduce supply chain vulnerabilities and ensure a more resilient supply of REEs.

Investment in Recycling and Closed-Loop Systems

Tesla is investing in technologies to recycle and reuse rare earth elements from end-of-life products:

- Recycling Technologies: Advanced recycling methods aim to recover valuable REEs from discarded electronics and batteries.

- Closed-Loop Systems: Developing closed-loop systems to minimize waste and maximize the reuse of REEs within the manufacturing process.

Recycling offers significant economic and environmental benefits, reducing reliance on primary mining and minimizing the environmental impact of REE production.

Design Optimization for Reduced Rare Earth Dependence

Tesla is actively exploring design optimizations to reduce the amount of rare earth materials needed in Optimus:

- Material Substitution: Investigating alternative materials with similar properties to REEs where possible.

- Design Modifications: Optimizing the robot's design to minimize the use of REEs without compromising performance.

These efforts aim to enhance resource efficiency and further reduce reliance on vulnerable supply chains.

Securing the Future of Optimus: Addressing Rare Earth Supply Chain Challenges

Tesla faces significant challenges in securing the rare earth materials needed for its ambitious Optimus robot. The reliance on China for a large portion of the global supply, coupled with ethical and environmental concerns surrounding REE mining, necessitates a proactive and multi-faceted approach. Tesla's strategies of diversifying supply sources, investing in recycling technologies, and optimizing robot design are crucial steps toward building a more sustainable and resilient supply chain. These efforts are not only vital for Optimus's success but also crucial for the long-term sustainability of the robotics industry. Learn more about how Tesla's approach to the rare earth supply chain will shape the future of robotics and sustainable technology.

Featured Posts

-

Hudsons Bay Pointing To Sale Of 65 Leases

Apr 24, 2025

Hudsons Bay Pointing To Sale Of 65 Leases

Apr 24, 2025 -

Faa Investigates Las Vegas Airport Collision Risks

Apr 24, 2025

Faa Investigates Las Vegas Airport Collision Risks

Apr 24, 2025 -

White House Announces Drop In Illegal Border Crossings Between U S And Canada

Apr 24, 2025

White House Announces Drop In Illegal Border Crossings Between U S And Canada

Apr 24, 2025 -

Decline In Border Apprehensions Reported By White House Canada U S Border

Apr 24, 2025

Decline In Border Apprehensions Reported By White House Canada U S Border

Apr 24, 2025 -

Navigate The Private Credit Boom 5 Essential Dos And Don Ts

Apr 24, 2025

Navigate The Private Credit Boom 5 Essential Dos And Don Ts

Apr 24, 2025