TBS Safety & Nebofleet Partner To Automate Workboat Safety

Table of Contents

Enhanced Safety through Automated Reporting & Monitoring

This partnership leverages cutting-edge technology to streamline reporting processes, minimizing human error and maximizing data accuracy. Real-time workboat safety monitoring becomes a reality, providing a constant stream of crucial information. This integrated approach enables:

- Real-time data collection: Constantly monitor vessel location, speed, heading, and environmental conditions (weather, currents, etc.), providing a comprehensive picture of operational context.

- Automated reporting of near misses and incidents: Seamlessly record and report near misses and incidents, ensuring thorough documentation and prompt investigation. This automated safety reporting for workboats reduces delays and ensures consistency.

- Improved compliance with safety regulations: Automated systems ensure adherence to all relevant safety regulations and standards, reducing the risk of penalties and legal issues. Workboat safety compliance automation becomes a key benefit.

- Proactive identification of potential hazards: By analyzing real-time data, the system can proactively identify potential hazards, allowing for timely intervention and risk mitigation.

- Integration with existing safety management systems: Seamless integration with existing systems ensures a smooth transition and minimizes disruption to existing workflows.

Improved Efficiency and Reduced Downtime with Automated Workflows

Automating safety-related tasks frees up valuable time and resources, allowing safety officers to focus on strategic initiatives rather than administrative burdens. Automated workboat workflows significantly improve efficiency and reduce downtime by:

- Automated pre-trip inspections: Digital checklists and automated data collection ensure thorough pre-trip inspections, reducing the risk of mechanical failures and human oversight.

- Automated crew training and certification tracking: Streamline crew training and certification management, ensuring all personnel are adequately trained and certified for their roles.

- Automated risk assessments: Regular and automated risk assessments provide continuous monitoring and identification of evolving hazards.

- Reduced administrative burden on safety officers: Automation handles repetitive tasks, allowing safety officers to focus on higher-level strategic planning and proactive safety initiatives.

- Faster response times to incidents: Automated alerts and communication systems ensure faster response times to incidents, minimizing potential damage and consequences. This contributes directly to reducing downtime through automated safety.

Data-Driven Insights for Proactive Safety Management

The combined data from TBS Safety and Nebofleet provides invaluable insights into safety trends, enabling proactive risk mitigation. This data-driven workboat safety approach offers:

- Data analysis to identify high-risk areas and activities: Identify patterns and trends in accidents and near misses to pinpoint areas needing immediate attention.

- Predictive modeling to anticipate potential accidents: Leverage data analysis to predict potential accidents, allowing for preemptive measures to be put in place.

- Targeted safety training based on identified needs: Develop and deliver targeted safety training based on specific identified risks and needs.

- Continuous improvement of safety procedures: Continuously evaluate and improve safety procedures based on data-driven insights, creating a culture of continuous improvement.

- Improved return on investment (ROI) through reduced accidents and downtime: The cost savings from reduced accidents and downtime quickly offset the investment in workboat safety automation and analytics.

Case Study: North Sea Towing

North Sea Towing, a leading provider of offshore towing services, implemented the TBS Safety and Nebofleet integrated system. Within six months, they experienced a 25% reduction in near misses and a 15% decrease in downtime due to safety-related incidents. This demonstrably improved their operational efficiency and strengthened their commitment to proactive workboat safety management.

The Future of Workboat Safety is Automated

The TBS Safety and Nebofleet partnership offers a powerful solution for enhancing workboat safety, improving efficiency, and enabling data-driven decision-making. By automating key safety processes, the industry can significantly reduce accidents, minimize downtime, and create a safer working environment for all. Improve your workboat safety with automation; the benefits are clear. Learn more about how TBS Safety and Nebofleet can help automate your workboat safety procedures today. Contact us at [insert contact information] or visit [insert website link] for workboat safety automation solutions.

Featured Posts

-

On N Est Pas Stresse Trois Jeunes Du Bocage Ornais Partent Pour 8 000 Km

May 02, 2025

On N Est Pas Stresse Trois Jeunes Du Bocage Ornais Partent Pour 8 000 Km

May 02, 2025 -

Shrimp Ramen Stir Fry Step By Step Guide

May 02, 2025

Shrimp Ramen Stir Fry Step By Step Guide

May 02, 2025 -

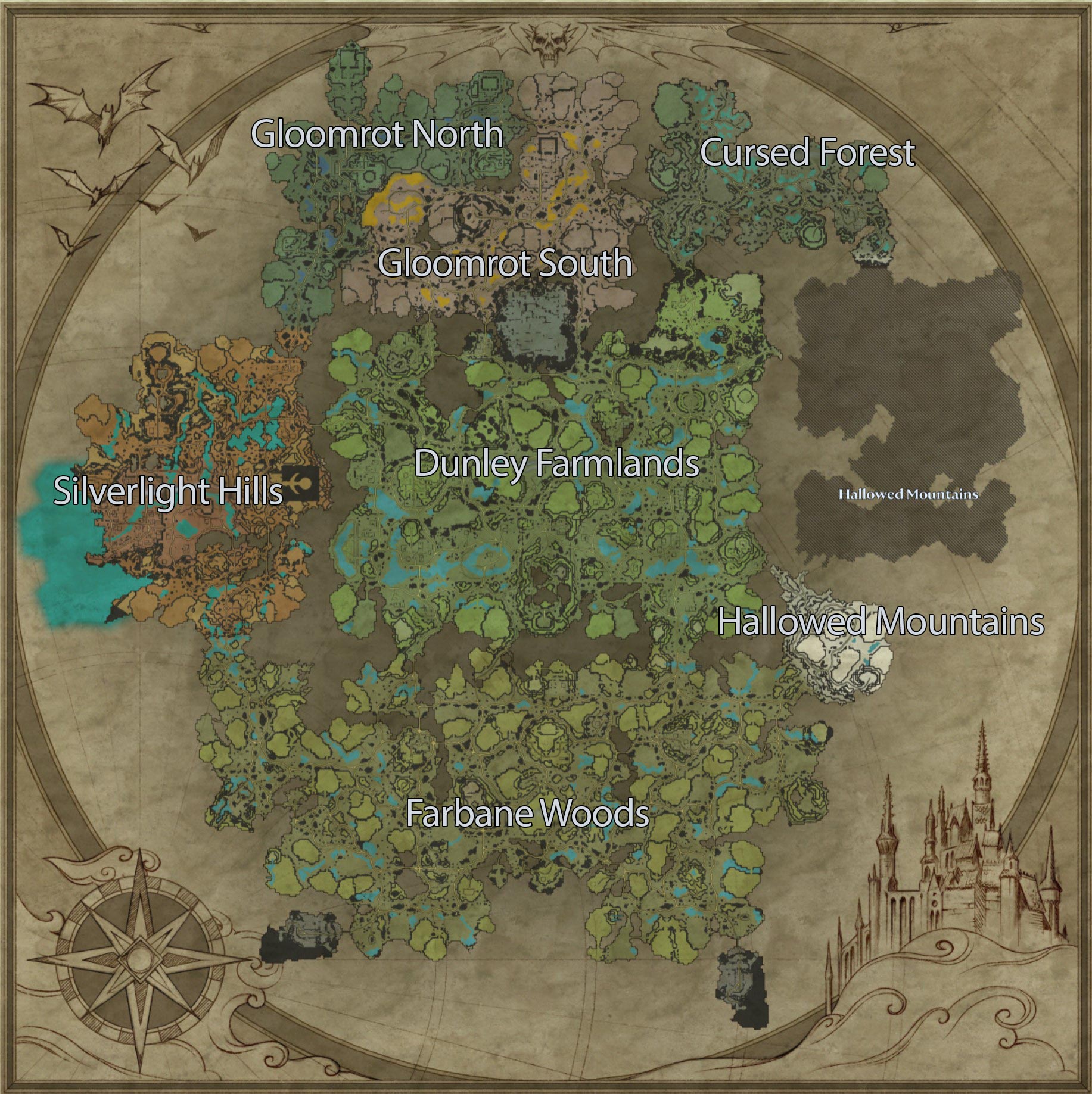

Invest Smart A Map Of The Countrys Rising Business Hot Spots

May 02, 2025

Invest Smart A Map Of The Countrys Rising Business Hot Spots

May 02, 2025 -

Remembering Priscilla Pointer Dallas And Carrie Star Passes Away At 100

May 02, 2025

Remembering Priscilla Pointer Dallas And Carrie Star Passes Away At 100

May 02, 2025 -

Economic Slowdown Assessing President Bidens Role

May 02, 2025

Economic Slowdown Assessing President Bidens Role

May 02, 2025

Latest Posts

-

Sony Play Station Beta Program What We Know So Far

May 02, 2025

Sony Play Station Beta Program What We Know So Far

May 02, 2025 -

Sony Play Station Christmas Voucher Glitch Users Receive Free Credit Compensation

May 02, 2025

Sony Play Station Christmas Voucher Glitch Users Receive Free Credit Compensation

May 02, 2025 -

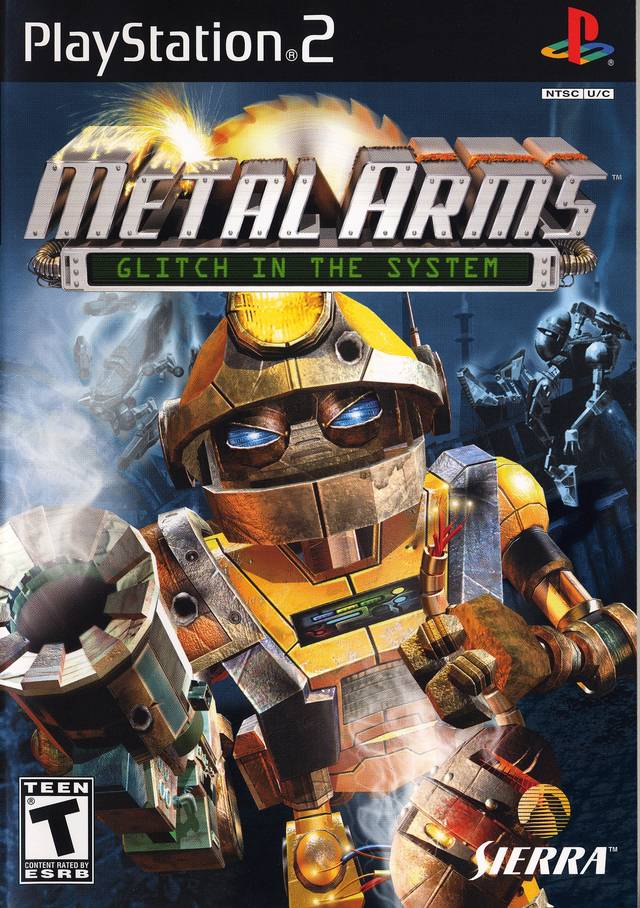

Hidden Gem Alert Underrated Game Hits Ps Plus In October 2024

May 02, 2025

Hidden Gem Alert Underrated Game Hits Ps Plus In October 2024

May 02, 2025 -

October 2024s Ps Plus Offering An Underappreciated Masterpiece

May 02, 2025

October 2024s Ps Plus Offering An Underappreciated Masterpiece

May 02, 2025 -

Underrated Ps Plus Game Of October 2024 A Hidden Treasure

May 02, 2025

Underrated Ps Plus Game Of October 2024 A Hidden Treasure

May 02, 2025