Steel Industry Decarbonization: The Impact Of Eramet's EraLow

Table of Contents

Understanding Eramet's eraLow Technology

Eramet's eraLow represents a significant advancement in steelmaking, offering a low-carbon alternative to traditional blast furnace methods. Its core differentiator lies in its reliance on a direct reduction process, utilizing hydrogen instead of coal for the reduction of iron ore. This fundamental shift drastically reduces the carbon footprint associated with steel production.

-

Core Technology: eraLow employs a direct reduction process, bypassing the energy-intensive and carbon-intensive blast furnace stage. Hydrogen, a clean energy carrier, plays a crucial role in reducing iron ore to metallic iron. This significantly reduces reliance on coking coal, a major source of GHG emissions in conventional steelmaking.

-

CO2 Emission Reduction: Compared to traditional blast furnace methods, eraLow achieves a substantial reduction in CO2 emissions. While precise figures vary depending on the specific energy mix used to produce the hydrogen, Eramet reports significant reductions, paving the way for low-carbon and green steel production.

-

Sustainable Materials and Processes: Beyond the use of hydrogen, eraLow incorporates other sustainability measures. This includes optimized energy management and the exploration of using recycled materials within the process, further minimizing its environmental impact. The focus is on creating a circular economy for steel production.

Environmental Benefits of eraLow

The environmental benefits of Eramet's eraLow are substantial and directly contribute to global efforts to mitigate climate change.

-

CO2 Emission Comparison: Studies show that eraLow can reduce CO2 emissions by up to 90% compared to conventional blast furnace steelmaking. This dramatic reduction offers a powerful tool in combatting climate change and meeting global emission reduction targets.

-

Reduced Pollutant Emissions: Beyond CO2, eraLow significantly reduces the emission of other pollutants associated with traditional steelmaking, such as particulate matter and sulfur oxides. This contributes to improved air quality and a healthier environment.

-

Contribution to Climate Goals: The deployment of eraLow technology aligns perfectly with the goals of the Paris Agreement. By significantly lowering GHG emissions from steel production, eraLow contributes significantly to limiting global warming and protecting the planet.

Economic Implications and Scalability of eraLow

While environmental benefits are significant, the economic viability and scalability of eraLow are equally critical for widespread adoption.

-

Cost-Competitiveness: While initial investments in eraLow technology might be higher than those for traditional blast furnaces, the long-term cost-competitiveness is improving as the cost of renewable energy decreases and technological advancements are made. The reduced environmental penalties and potential for carbon pricing mechanisms also contribute to its economic viability.

-

Job Creation and Economic Growth: The transition to eraLow presents opportunities for job creation in the green steel sector, particularly in areas related to hydrogen production, plant construction, and operation. This presents opportunities for economic growth in regions focused on sustainable industrial development.

-

Scalability Challenges: Scaling up eraLow production to meet global steel demand requires significant investments in infrastructure, including renewable energy sources to power the plants and the development of efficient hydrogen supply chains. This will necessitate collaboration between governments, industries, and research institutions.

Challenges and Future Prospects for eraLow and Steel Decarbonization

Despite its potential, widespread adoption of eraLow and achieving full decarbonization of the steel industry faces several challenges.

-

Renewable Energy Dependence: The success of eraLow hinges on the availability of renewable energy sources like solar, wind, and hydropower to produce the green hydrogen needed for the reduction process. Securing a reliable and affordable supply of renewable energy is crucial.

-

Policy Support and Incentives: Government policies, including carbon pricing mechanisms, subsidies, and tax incentives, are vital to stimulate investment and accelerate the adoption of eraLow and other low-carbon steelmaking technologies. Strong policy frameworks are essential for driving this transition.

-

Collaboration and Partnerships: Addressing the technological, economic, and infrastructural challenges requires collaborative efforts involving steel producers, technology developers, energy providers, and policymakers. Strong partnerships are essential to expedite the transition to sustainable steel production.

Conclusion

Eramet's eraLow technology offers a compelling pathway towards steel industry decarbonization. Its significant reduction in greenhouse gas emissions, coupled with the potential for economic growth and job creation, makes it a crucial technology for a sustainable future. While challenges exist regarding scalability, renewable energy infrastructure, and policy support, addressing these hurdles through collaboration and strategic investment is paramount. The future of sustainable steel production hinges on innovative solutions like Eramet's eraLow. By investing in and supporting the development and deployment of low-carbon steelmaking technologies, including further advancements in green steel production methods, we can pave the way towards a greener, more sustainable future. Learn more about Eramet's eraLow and its contribution to a decarbonized steel industry today!

Featured Posts

-

Pretzfeld Kirschbluete In Der Fraenkischen Schweiz Bald Beginnt Die Saison

May 14, 2025

Pretzfeld Kirschbluete In Der Fraenkischen Schweiz Bald Beginnt Die Saison

May 14, 2025 -

Sean Diddy Combs Decline Insider Perspectives

May 14, 2025

Sean Diddy Combs Decline Insider Perspectives

May 14, 2025 -

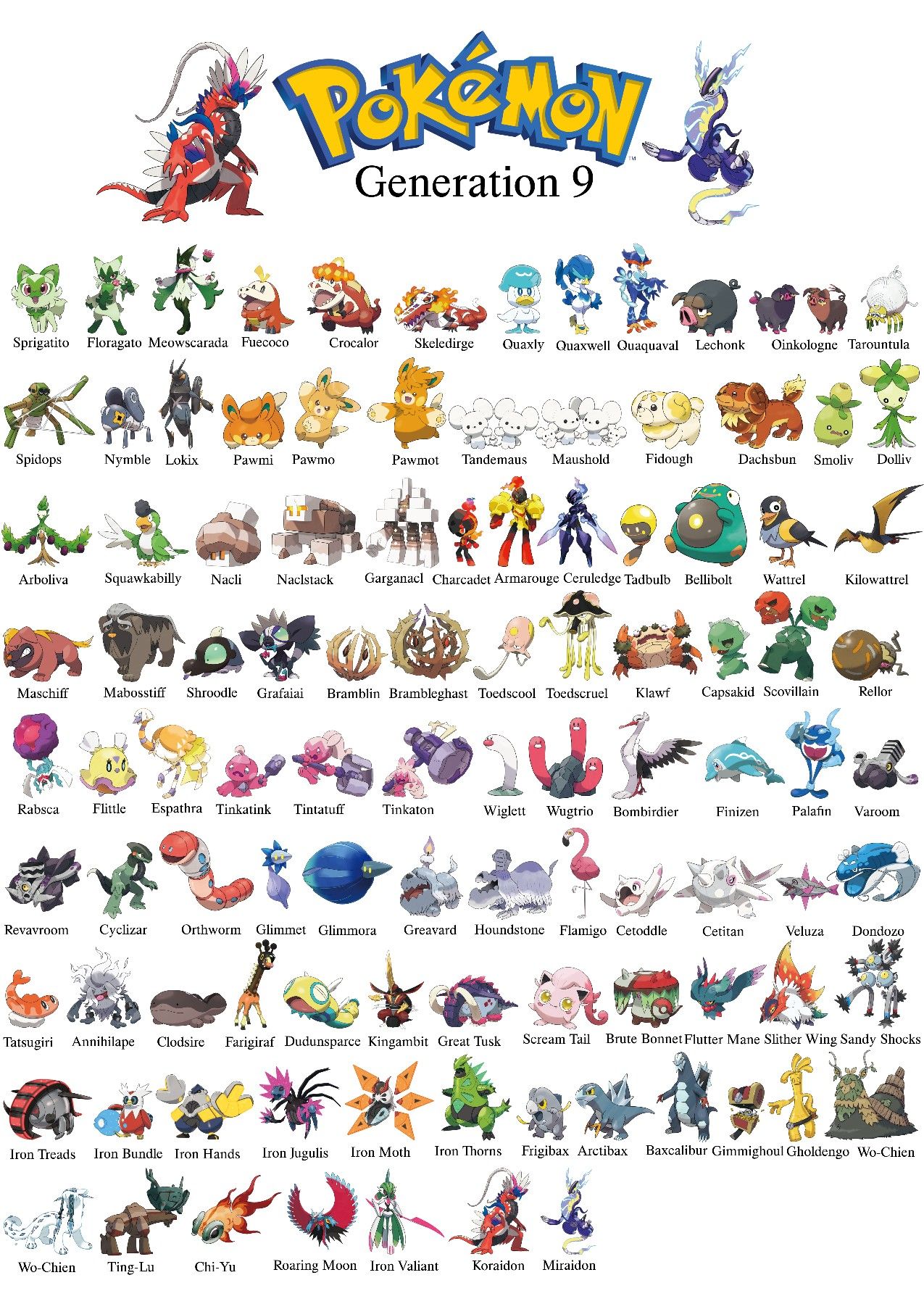

Best Starter Pokemon By Generation A Ranked Analysis

May 14, 2025

Best Starter Pokemon By Generation A Ranked Analysis

May 14, 2025 -

Captain America Brave New World Disney Release Date

May 14, 2025

Captain America Brave New World Disney Release Date

May 14, 2025 -

Confirmed 7 Players Amorim Wants Manchester United To Sign

May 14, 2025

Confirmed 7 Players Amorim Wants Manchester United To Sign

May 14, 2025