Stadium Track Resurfacing For Championship Season

Table of Contents

Assessing Your Existing Track for Resurfacing Needs

Before embarking on stadium track resurfacing, a thorough track inspection is paramount. This assessment determines the extent of damage, informs material selection, and provides a realistic budget. A professional track assessment will identify critical issues that might otherwise be overlooked.

- Signs of Wear and Tear: Look for cracks, alligatoring (a pattern of interconnected cracks), fading, discoloration, and surface unevenness. These indicate deterioration and potential safety hazards.

- Impact of Weather and Usage: Consider the climate and the intensity of track use. Exposure to extreme temperatures, heavy rainfall, and frequent use accelerates track degradation. High-traffic areas will show more wear than others.

- Identifying Problematic Areas: Pinpointing specific areas of concern, such as sections with significant cracking or depressions, is crucial for effective repairs and resurfacing.

- Different Track Surfaces: Understanding your existing track material (polyurethane, rubber, asphalt) is vital, as each requires a specific approach to resurfacing and maintenance. Older asphalt tracks, for instance, may require more extensive sub-base work before resurfacing.

Professional track inspections by qualified contractors are highly recommended. They possess the expertise to identify hidden damage and recommend the most suitable resurfacing solution. Ignoring necessary track repairs can lead to more extensive and costly problems down the line.

Choosing the Right Resurfacing Material for Your Stadium Track

Selecting the appropriate resurfacing material significantly impacts the longevity, performance, and overall cost-effectiveness of your stadium track. Several materials are commonly used, each with its own advantages and disadvantages.

- Polyurethane: Known for its excellent shock absorption, durability, and consistent performance, polyurethane is a popular choice for high-performance running tracks. However, it's generally more expensive than other options.

- Rubber: Rubber surfacing offers good durability and shock absorption, making it a suitable option for various athletic activities. It tends to be more affordable than polyurethane but may not offer the same level of performance for elite-level competitions.

- Asphalt: While more economical, asphalt tracks are less durable and require more frequent maintenance. They are generally not suitable for high-performance athletic events.

Factors to consider when selecting the material include:

- Climate: The material's ability to withstand extreme temperatures and weather conditions is critical.

- Budget: Polyurethane is more expensive than rubber or asphalt.

- Intended Use: High-performance events necessitate materials that meet IAAF/USA Track & Field regulations to ensure fair competition.

Choosing the correct material ensures compliance with regulations and maximizes track performance and lifespan.

The Stadium Track Resurfacing Process: A Step-by-Step Guide

The stadium track resurfacing process is complex and requires skilled professionals. Here's a general outline of the steps involved:

- Preparation: This crucial stage involves cleaning the existing surface to remove debris, repairing any underlying damage to the base, and ensuring a level and stable foundation.

- Application of the New Surface: This involves precisely applying the chosen resurfacing material according to the manufacturer's instructions. This often requires specialized equipment and expertise.

- Curing Time: The new surface needs sufficient time to cure properly, ensuring its strength and durability. This period varies depending on the material used and environmental conditions.

- Final Inspection and Quality Control: A thorough inspection verifies the surface's compliance with specifications, checking for evenness, appropriate thickness, and overall quality.

Throughout the process, adhering to the manufacturer's instructions and employing experienced contractors who adhere to safety regulations is paramount.

Maintaining Your Newly Resurfaced Stadium Track

Proactive maintenance is crucial to extend the lifespan of your newly resurfaced stadium track and minimize the need for costly repairs.

- Regular Cleaning: Regular sweeping and occasional power washing remove debris and dirt that can damage the surface.

- Preventative Maintenance: Addressing minor damage promptly (e.g., small cracks or loose surfaces) prevents larger issues from developing.

- Scheduling Regular Professional Inspections: Professional inspections identify potential problems before they become major issues, saving money and ensuring athlete safety.

Following the manufacturer's guidelines for cleaning products and procedures is essential, as using inappropriate chemicals can damage the track surface. Remember, proactive maintenance not only extends track life but also yields significant long-term cost savings.

Conclusion

Timely stadium track resurfacing is an investment that pays dividends. A high-quality running track ensures athlete safety, enhances performance, and contributes to successful championship events. Through careful assessment, appropriate material selection, and diligent maintenance, you can maximize your track's lifespan and safeguard your investment. Invest in your stadium's future and ensure a championship-worthy running track. Contact a reputable track resurfacing contractor today for a consultation and get your stadium track ready for the championship season!

Featured Posts

-

The Unexpected Hit Fake Henry Cavill Captain Britain Trailer Goes Viral

May 12, 2025

The Unexpected Hit Fake Henry Cavill Captain Britain Trailer Goes Viral

May 12, 2025 -

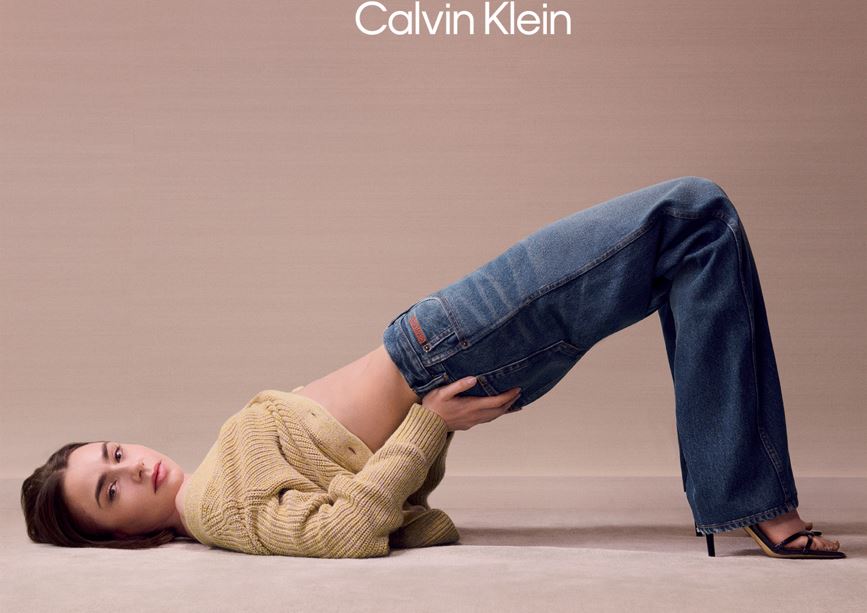

Lily Collins Calvin Klein Campaign A Look At The Photoshoot

May 12, 2025

Lily Collins Calvin Klein Campaign A Look At The Photoshoot

May 12, 2025 -

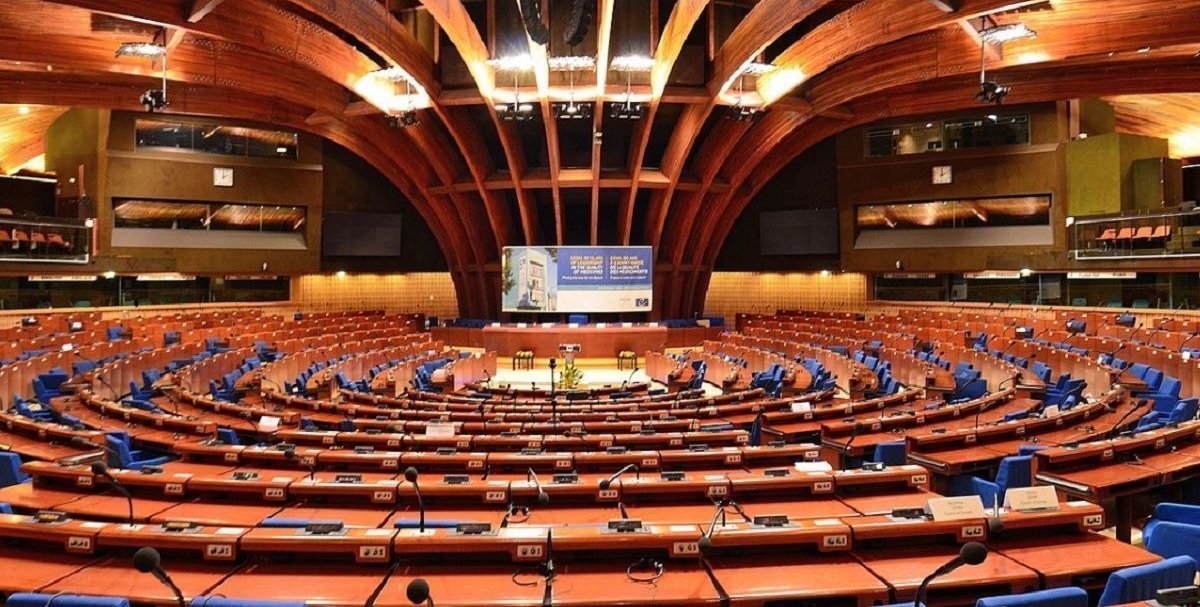

Ukrayina Ta Mirni Peregovori Pozitsiya Dzhonsona Schodo Planu Trampa

May 12, 2025

Ukrayina Ta Mirni Peregovori Pozitsiya Dzhonsona Schodo Planu Trampa

May 12, 2025 -

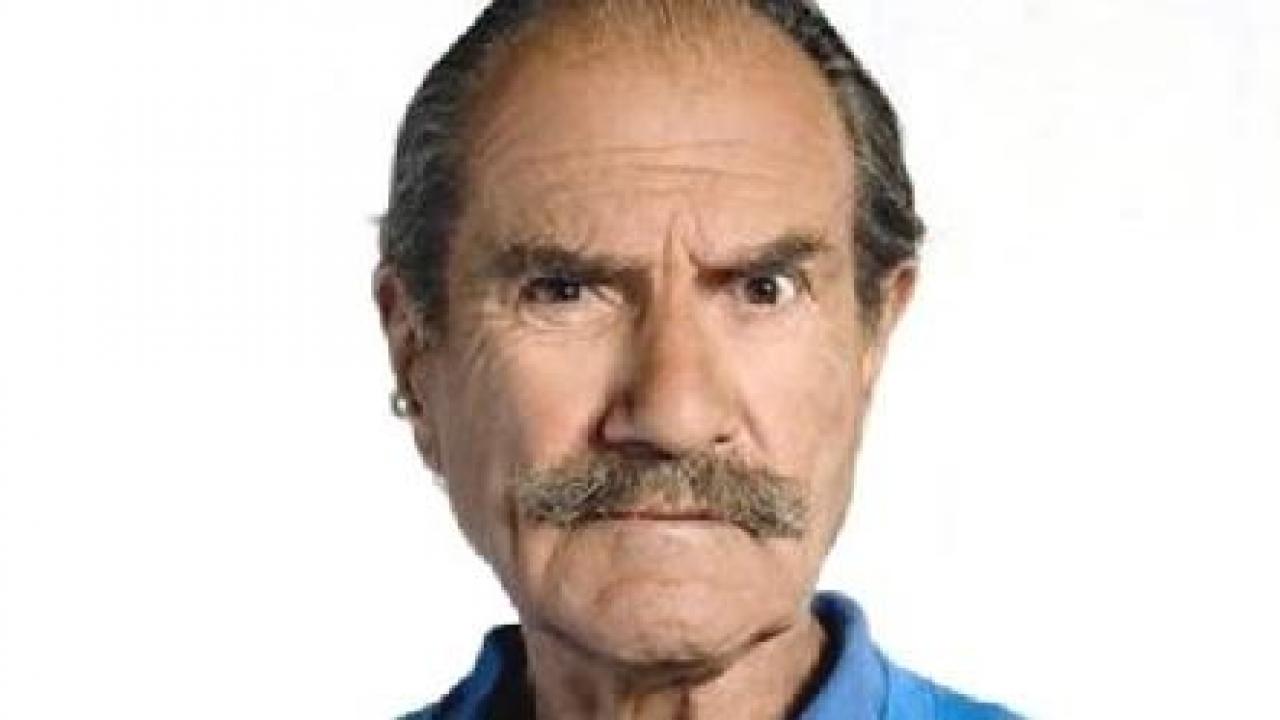

Scenes De Menages Gerard Hernandez Parle De Son Partenariat Avec Chantal Ladesou

May 12, 2025

Scenes De Menages Gerard Hernandez Parle De Son Partenariat Avec Chantal Ladesou

May 12, 2025 -

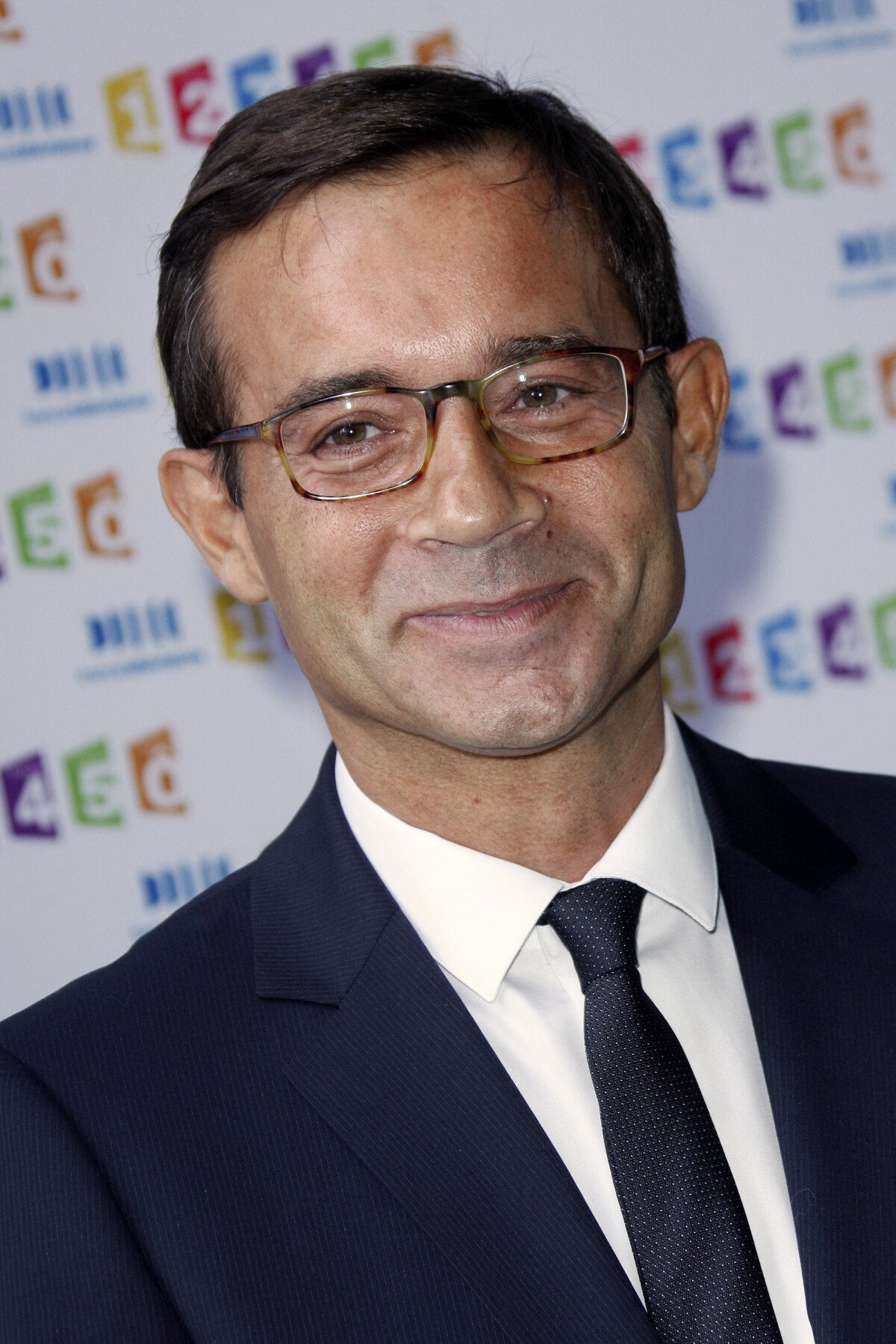

Jean Luc Delarue Le Recit Cash D Antoine Dulery D Une Rencontre Froide

May 12, 2025

Jean Luc Delarue Le Recit Cash D Antoine Dulery D Une Rencontre Froide

May 12, 2025

Latest Posts

-

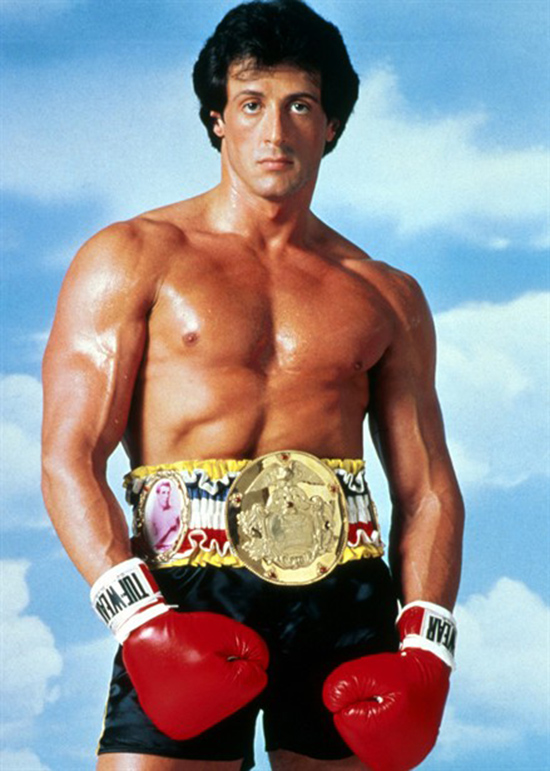

Which Rocky Movie Touches Stallone The Most His Answer Will Surprise You

May 12, 2025

Which Rocky Movie Touches Stallone The Most His Answer Will Surprise You

May 12, 2025 -

Sylvester Stallones Favorite Rocky Movie The Franchises Most Emotional Entry

May 12, 2025

Sylvester Stallones Favorite Rocky Movie The Franchises Most Emotional Entry

May 12, 2025 -

The One Movie Sylvester Stallone Directed But Didnt Star In A Critical And Commercial Failure

May 12, 2025

The One Movie Sylvester Stallone Directed But Didnt Star In A Critical And Commercial Failure

May 12, 2025 -

Action Thriller Armor Starring Sylvester Stallone Free Online Streaming

May 12, 2025

Action Thriller Armor Starring Sylvester Stallone Free Online Streaming

May 12, 2025 -

Sylvester Stallone Action Thriller Armor Now Streaming Free

May 12, 2025

Sylvester Stallone Action Thriller Armor Now Streaming Free

May 12, 2025