Solving OEM Supply Chain Problems: SG Wireless Expands Manufacturing Collaborations

Table of Contents

The Challenges Facing OEMs in Today's Global Market

OEMs navigate a complex web of interconnected factors that significantly impact their supply chains. These challenges often combine to create significant hurdles to efficient production and timely delivery.

Increased Component Costs and Shortages

The global market experiences frequent component shortages, impacting various sectors.

- Automotive: Semiconductor shortages have led to production halts and increased vehicle prices.

- Electronics: Demand for specific chips and rare earth minerals often outstrips supply, delaying product launches.

- Medical Devices: Shortages of crucial components can hinder the production of life-saving equipment.

Geopolitical instability further exacerbates these issues. Trade wars, sanctions, and political unrest can disrupt supply routes and significantly impact the availability of essential materials. Fluctuating demand also strains manufacturing capacity, leading to bottlenecks and delays. Effective OEM supply chain disruption management requires proactive strategies to mitigate these risks.

Geopolitical Instability and its Impact on Manufacturing

Relying on single-source suppliers presents significant risk. Geopolitical events, such as trade wars and sanctions, can severely impact sourcing strategies. For example, relying heavily on a supplier in a region experiencing political instability exposes OEMs to potential disruptions. Supply chain diversification is crucial for risk mitigation and ensuring business continuity. Building a robust global supply chain requires carefully considering geopolitical factors and implementing effective risk management strategies.

The Growing Demand for Faster Time-to-Market

The pressure to deliver products quickly is immense. Consumers expect immediate gratification, and competition is fierce. OEMs need agile and responsive supply chains to meet these demands. This requires advanced planning, efficient logistics, and the ability to adapt to changing market conditions. Time-to-market is a key performance indicator for many OEMs, and streamlining the supply chain is critical to achieving competitive advantage.

SG Wireless's Strategic Approach to Solving OEM Supply Chain Issues

SG Wireless adopts a multi-pronged strategy to address the challenges facing OEMs and create more resilient and efficient supply chains.

Expanding Manufacturing Partnerships

SG Wireless is actively expanding its manufacturing partnerships with various manufacturers across diverse geographical locations. This strategic approach ensures:

- Increased Capacity: Multiple manufacturing sites provide greater production capacity, mitigating the impact of localized disruptions.

- Reduced Risk: Diversification minimizes the impact of any single event affecting a specific region or supplier.

- Enhanced Flexibility: The ability to shift production between different sites improves adaptability to changing demand and unforeseen circumstances.

This geographically diversified network contributes significantly to creating a more resilient global manufacturing footprint.

Investing in Advanced Technologies and Automation

SG Wireless invests heavily in advanced technologies and automation to enhance efficiency and responsiveness throughout its supply chain. This includes:

- AI-powered predictive analytics: Forecasting demand and potential disruptions with greater accuracy.

- Robotics and automation: Optimizing production processes and reducing reliance on manual labor.

- IoT-enabled tracking and monitoring: Providing real-time visibility into inventory levels and shipment status.

These technological advancements contribute significantly to solving supply chain problems by improving speed, efficiency, and predictability.

Strengthening Supply Chain Visibility and Transparency

SG Wireless prioritizes improving supply chain visibility and transparency by implementing robust real-time tracking and data analytics systems. This enhanced visibility allows for:

- Better forecasting: Accurately predicting demand fluctuations and proactively managing inventory.

- Effective risk management: Identifying potential disruptions early and taking appropriate mitigation measures.

- Improved decision-making: Data-driven insights enable informed decisions across all aspects of the supply chain.

The Benefits of SG Wireless's Expanded Manufacturing Collaborations for OEMs

The strategic initiatives undertaken by SG Wireless offer significant advantages for its OEM partners.

Improved Product Availability and Reduced Lead Times

Expanded manufacturing partnerships translate directly into faster delivery of components, leading to:

- Reduced lead times: Getting products to market faster and meeting customer demands promptly.

- Improved product availability: Minimizing stockouts and ensuring consistent supply to OEM production lines. This contributes significantly to on-time delivery and customer satisfaction.

Enhanced Supply Chain Resilience and Reduced Risk

Diversification significantly minimizes the impact of disruptions:

- Supply chain resilience: The ability to withstand unforeseen events and maintain operations without major disruptions.

- Risk mitigation: Reducing the vulnerability to geopolitical instability, natural disasters, or supplier-specific issues. This translates into increased supply chain stability and peace of mind for OEMs.

Cost Optimization and Improved Profitability

Increased efficiency and reduced risk directly contribute to cost savings:

- Supply chain cost reduction: Optimizing logistics, reducing waste, and minimizing the impact of disruptions.

- Improved profitability: Increased efficiency translates into higher profit margins for OEMs.

Conclusion: Solving OEM Supply Chain Problems with SG Wireless

SG Wireless proactively addresses OEM supply chain challenges through expanded manufacturing collaborations, strategic technology investments, and a commitment to supply chain visibility. The benefits for OEMs are significant: enhanced resilience, reduced lead times, cost optimization, and ultimately, improved profitability. Contact SG Wireless today to discover how our solutions can help you solve your OEM supply chain problems and achieve greater efficiency and profitability. Let us help you build a more resilient and efficient supply chain for a more secure and successful future.

Featured Posts

-

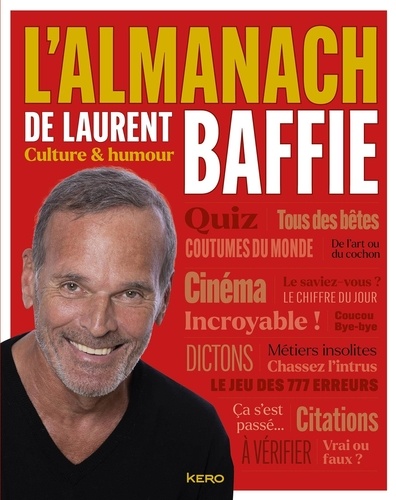

Thierry Ardisson Accuse De Sexisme Analyse De L Affaire Baffie

May 26, 2025

Thierry Ardisson Accuse De Sexisme Analyse De L Affaire Baffie

May 26, 2025 -

B C Billionaire Targets Hudsons Bay Leases For New Shopping Mall

May 26, 2025

B C Billionaire Targets Hudsons Bay Leases For New Shopping Mall

May 26, 2025 -

Formula 1s Forties A Look At Drivers Continued Success Or Decline

May 26, 2025

Formula 1s Forties A Look At Drivers Continued Success Or Decline

May 26, 2025 -

Hasil Fp 1 Moto Gp Inggris 2025 Jam Tayang Live Race Di Trans7

May 26, 2025

Hasil Fp 1 Moto Gp Inggris 2025 Jam Tayang Live Race Di Trans7

May 26, 2025 -

Jadwal Lengkap Moto Gp Inggris Di Silverstone Update Klasemen And Posisi Marquez

May 26, 2025

Jadwal Lengkap Moto Gp Inggris Di Silverstone Update Klasemen And Posisi Marquez

May 26, 2025

Latest Posts

-

As Protagonistas Pop Feminino Brilha No Funn Festival

May 27, 2025

As Protagonistas Pop Feminino Brilha No Funn Festival

May 27, 2025 -

Fruehjahrskonzert In Viehdorf Programm Und Karten

May 27, 2025

Fruehjahrskonzert In Viehdorf Programm Und Karten

May 27, 2025 -

Fruehlingskonzert Im Musikverein Viehdorf Oesterreichische Musik

May 27, 2025

Fruehlingskonzert Im Musikverein Viehdorf Oesterreichische Musik

May 27, 2025 -

Finding Information On Bangladesh A Guide To Using Bangladeshinfo Com

May 27, 2025

Finding Information On Bangladesh A Guide To Using Bangladeshinfo Com

May 27, 2025 -

Bangladeshinfo Com News Information And Resources For Bangladesh

May 27, 2025

Bangladeshinfo Com News Information And Resources For Bangladesh

May 27, 2025