Reviving American Manufacturing: The Reality Of Job Creation

Table of Contents

The Current State of American Manufacturing

The landscape of American manufacturing is complex, shaped by a confluence of global trends and domestic policies. Understanding this landscape is crucial to accurately assessing the potential for job creation.

Reshoring and its Impact

The trend of reshoring, bringing manufacturing back to the US from overseas, is gaining momentum. Several factors contribute to this shift:

- Increased transportation costs: Global shipping costs have risen significantly, making importing goods less economically advantageous.

- Geopolitical instability: Disruptions to global supply chains due to political instability and trade wars highlight the risks of relying on overseas production.

- Consumer demand for "Made in America" products: A growing segment of consumers actively seek out products manufactured domestically, driving demand for reshored goods.

- Government incentives: Federal and state governments are increasingly offering tax breaks and subsidies to encourage companies to bring manufacturing back to the US.

These factors are contributing to a slow but steady increase in domestic production and the creation of manufacturing jobs. However, the scale of reshoring and its impact on overall job creation remains to be seen. The transition from overseas manufacturing to domestic production is gradual and requires significant investment.

Automation and its Effects on Employment

Automation is a double-edged sword for American manufacturing. While it increases productivity and reduces labor costs, it also leads to job displacement in some areas.

- Increased productivity: Automation technologies such as robotics and AI significantly enhance manufacturing efficiency.

- Reduced labor costs: Automation can lower labor costs in the long run, though initial investment can be substantial.

- Need for skilled workers: While automation reduces the need for unskilled labor, it creates a demand for skilled workers to operate, maintain, and program the automated systems.

- Potential job displacement in certain areas: Routine, repetitive tasks are most susceptible to automation, leading to job losses in these areas.

- Creation of new tech jobs: The development, implementation, and maintenance of automation technologies create new jobs in engineering, programming, and technical support.

The net impact of automation on manufacturing jobs is a subject of ongoing debate. The transition to a more automated manufacturing sector requires proactive measures to address the skills gap and ensure a smooth transition for displaced workers. This is closely linked to the broader concept of Industry 4.0 and its impact on employment.

The Skills Gap in Manufacturing

A significant challenge facing the revitalization of American manufacturing is the skills gap. Many available manufacturing jobs require specialized skills and training that many potential workers lack.

- Lack of vocational training: A decline in vocational training programs has led to a shortage of skilled workers in various manufacturing trades.

- Aging workforce: The manufacturing workforce is aging, leading to a loss of experienced workers and a need for skilled replacements.

- Need for upskilling and reskilling programs: Existing workers need opportunities to acquire new skills and adapt to technological advancements.

- Attracting younger generations to manufacturing careers: Manufacturing needs to be presented as a modern, high-tech, and rewarding career path to attract young talent.

Addressing the skills gap through robust vocational training, apprenticeships, and workforce development programs is essential for realizing the full potential of American manufacturing. Investing in education and training is a critical component of creating sustainable manufacturing jobs.

Factors Driving Job Growth in American Manufacturing

Despite the challenges, several factors are driving job growth in specific areas of American manufacturing.

Government Policies and Incentives

Government initiatives play a crucial role in supporting manufacturing growth and job creation.

- Tax breaks: Tax incentives encourage investment in new manufacturing facilities and equipment.

- Subsidies: Direct financial assistance can help offset the high costs of setting up and operating manufacturing facilities.

- Infrastructure investments: Improvements to roads, bridges, and transportation networks facilitate the efficient movement of goods.

- Trade policies: Trade agreements and tariffs can protect domestic manufacturers from unfair competition.

- Buy American initiatives: Government procurement policies that prioritize American-made products boost demand for domestically produced goods.

Effective government incentives and well-designed manufacturing policy are essential for fostering a thriving manufacturing sector.

Innovation and Technological Advancements

Technological innovation is a key driver of job creation in American manufacturing.

- Advanced materials: New materials with enhanced properties open up new possibilities for product design and manufacturing.

- 3D printing: Additive manufacturing technologies enable the production of complex parts with greater flexibility and customization.

- AI-powered automation: Artificial intelligence is revolutionizing manufacturing processes, enhancing efficiency and productivity.

- Increased efficiency and productivity: Technological advancements lead to increased output with less labor input, creating opportunities for higher-value jobs.

Investing in research and development, fostering innovation, and embracing new manufacturing technologies are vital for maintaining a competitive edge in the global market and generating high-paying jobs.

Growth in Specific Manufacturing Sectors

Certain sectors are experiencing significant growth and job creation.

- Renewable energy: The transition to renewable energy sources is creating a high demand for manufacturing jobs in solar panels, wind turbines, and energy storage systems.

- Aerospace: The aerospace industry is a major employer, requiring skilled workers for the design, manufacturing, and maintenance of aircraft and spacecraft.

- Pharmaceuticals: The pharmaceutical industry requires advanced manufacturing capabilities for the production of drugs and medical devices.

- Medical devices: The growing healthcare sector drives demand for innovative medical devices, creating specialized manufacturing jobs.

Challenges to Reviving American Manufacturing

Despite the positive trends, several challenges hinder the full revival of American manufacturing.

Competition from Overseas

American manufacturers face intense competition from countries with lower labor costs and less stringent regulations.

- China: China remains a dominant player in global manufacturing, offering significantly lower labor costs.

- Vietnam: Vietnam and other emerging economies are also becoming increasingly competitive in manufacturing.

- The importance of competitiveness: American manufacturers must find ways to compete on cost and efficiency to remain viable. This involves strategic investments, technological advancements, and a focus on higher-value-added products.

Supply Chain Issues

Global supply chain vulnerabilities have highlighted the need for greater resilience and diversification.

- Pandemic-related disruptions: The COVID-19 pandemic exposed the fragility of global supply chains, leading to shortages and disruptions.

- Geopolitical risks: Political instability and trade conflicts can also disrupt supply chains.

- The importance of diversifying supply chains: American manufacturers need to diversify their sourcing to reduce their reliance on single suppliers and minimize risk.

Environmental Regulations

Environmental regulations, while essential for protecting the environment, can impact manufacturing costs and competitiveness.

- Balancing environmental sustainability with economic growth: Finding ways to meet environmental standards while remaining competitive is crucial.

- Green manufacturing practices: Adopting environmentally friendly manufacturing processes can reduce costs in the long run and enhance a company's image. This includes adopting sustainable manufacturing principles and adhering to ESG (environmental, social, and governance) guidelines.

Conclusion

Reviving American manufacturing presents both significant opportunities and considerable challenges. While reshoring, technological advancements, and government policies offer pathways to job creation, overcoming the skills gap, competing with overseas manufacturers, and navigating supply chain vulnerabilities are crucial. The future of American manufacturing hinges on a concerted effort involving industry, government, and educational institutions.

Call to Action: Let's work together to bolster American manufacturing and unlock its vast potential for job creation. Learn more about supporting initiatives aimed at reviving American manufacturing and creating high-paying jobs in this vital sector. Keywords: American manufacturing, job creation, manufacturing jobs, reshoring, revitalizing manufacturing.

Featured Posts

-

First Steps China Begins Construction Of Its Space Based Supercomputer

May 21, 2025

First Steps China Begins Construction Of Its Space Based Supercomputer

May 21, 2025 -

Antiques Roadshow Appearance Leads To Us Couples Arrest In The Uk

May 21, 2025

Antiques Roadshow Appearance Leads To Us Couples Arrest In The Uk

May 21, 2025 -

The Closure Of Anchor Brewing Company What Happens Next

May 21, 2025

The Closure Of Anchor Brewing Company What Happens Next

May 21, 2025 -

Peppa Pigs Family Grows Anticipation Builds For The New Baby

May 21, 2025

Peppa Pigs Family Grows Anticipation Builds For The New Baby

May 21, 2025 -

Klopp Un Geri Doenuesue Bir Devrin Baslangici Mi

May 21, 2025

Klopp Un Geri Doenuesue Bir Devrin Baslangici Mi

May 21, 2025

Latest Posts

-

Watch For Damaging Winds Fast Moving Storms

May 21, 2025

Watch For Damaging Winds Fast Moving Storms

May 21, 2025 -

Match Report Fsv Mainz 05 Bayer 04 Leverkusen Matchday 34

May 21, 2025

Match Report Fsv Mainz 05 Bayer 04 Leverkusen Matchday 34

May 21, 2025 -

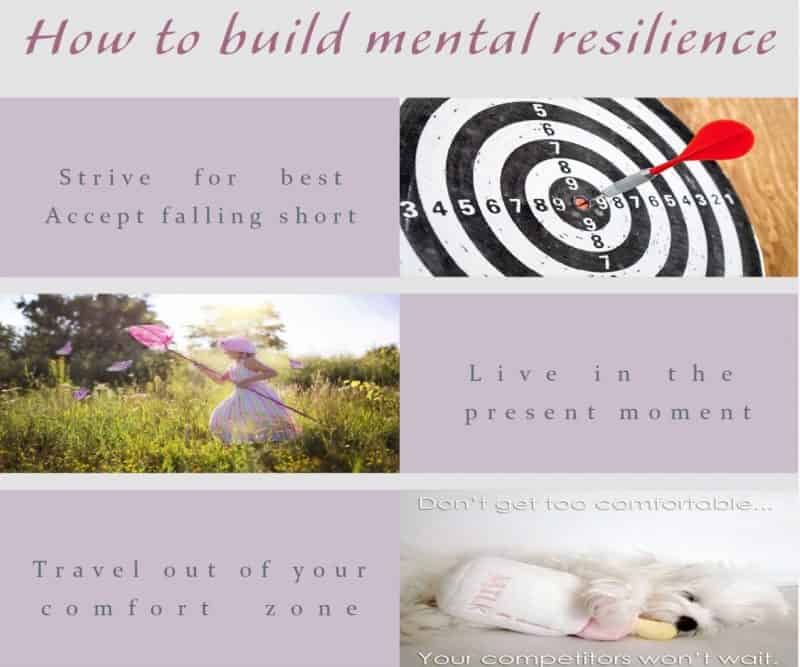

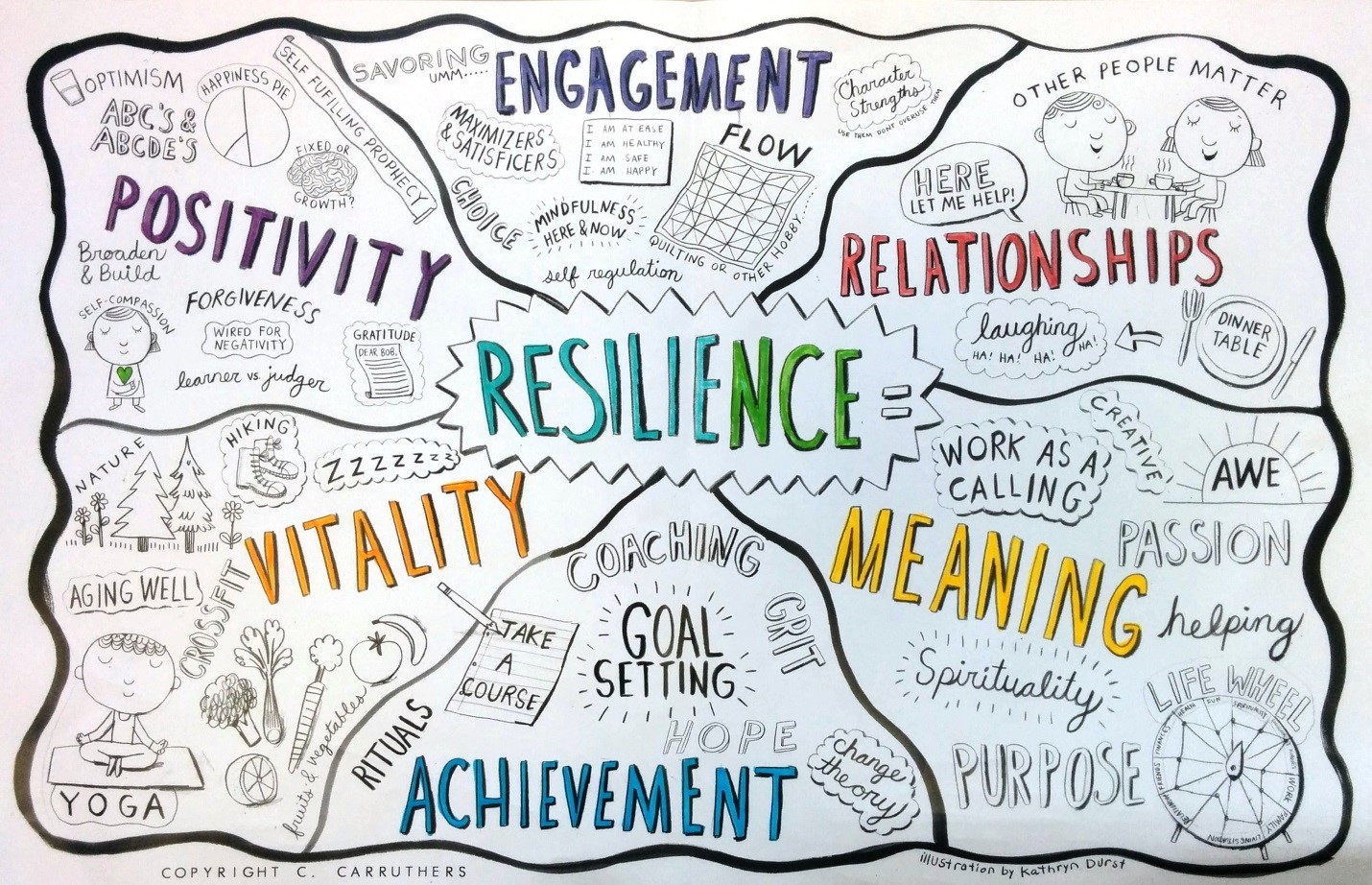

Understanding And Building Resilience For Better Mental Health

May 21, 2025

Understanding And Building Resilience For Better Mental Health

May 21, 2025 -

Mainz 05 Vs Leverkusen Complete Matchday 34 Report And Highlights

May 21, 2025

Mainz 05 Vs Leverkusen Complete Matchday 34 Report And Highlights

May 21, 2025 -

Building Mental Resilience Practical Steps For A Stronger You

May 21, 2025

Building Mental Resilience Practical Steps For A Stronger You

May 21, 2025