Process Safety Revolution: AI Technology In A New Patent Application

Table of Contents

Enhanced Risk Assessment and Prediction using AI

AI is rapidly changing how we approach process safety, offering significantly improved risk assessment and prediction capabilities. By analyzing massive datasets in real-time, AI algorithms can identify subtle anomalies and predict potential hazards with greater accuracy than traditional methods.

Real-time Anomaly Detection

AI algorithms can analyze vast amounts of real-time data from sensors and control systems, identifying deviations from normal operating parameters. This allows for the prediction of potential hazards before they escalate into incidents.

- Faster identification of anomalies: AI processes data far quicker than human operators, enabling immediate responses to developing problems. This speed significantly reduces reaction time to potential safety hazards.

- Proactive risk mitigation: By identifying anomalies early, AI facilitates proactive mitigation strategies, reducing the likelihood of accidents and minimizing their potential impact. This proactive approach is a key differentiator in modern process safety management.

- Improved accuracy in predicting failure points and potential hazards: AI algorithms, particularly those utilizing machine learning, can identify complex patterns and correlations that might be missed by human analysts, leading to more accurate hazard predictions. This contributes to more effective process safety management systems.

- Integration with existing SCADA systems for seamless data flow: Modern AI solutions are designed for seamless integration with existing Supervisory Control and Data Acquisition (SCADA) systems, ensuring a smooth transition and minimizing disruption to current operations. This streamlined integration is critical for successful AI implementation.

Predictive Maintenance through Machine Learning

Machine learning models analyze historical data and equipment performance to predict potential failures. This allows for scheduled maintenance before catastrophic events occur, minimizing safety risks and reducing downtime.

- Reduced downtime and operational costs: By predicting equipment failures, unnecessary downtime is avoided, leading to significant cost savings. This contributes to a more efficient and cost-effective process safety approach.

- Extended equipment lifespan: Proactive maintenance prevents premature equipment failure, extending its lifespan and reducing the need for frequent replacements. This leads to long-term cost benefits.

- Minimized safety risks associated with equipment failure: Preventing equipment failure directly mitigates safety risks associated with malfunctions, breakdowns, and potential leaks or spills. This is paramount for process safety.

- Optimized maintenance schedules based on real-time risk assessment: AI allows for dynamic maintenance scheduling, prioritizing critical equipment based on real-time risk assessment. This optimization strategy ensures maximum safety and efficiency.

Optimizing Safety Procedures with AI-driven Decision Support Systems

AI-powered decision support systems are transforming how operators respond to emergencies and manage safety protocols, leading to significantly improved safety outcomes.

Real-time Decision Support

During emergencies, AI can provide operators with real-time recommendations and insights, assisting them in making faster, more informed decisions.

- Improved operator training and preparedness: AI systems can simulate various emergency scenarios, providing valuable training opportunities for operators and enhancing their preparedness. This improvement in operator competency is crucial for better process safety.

- Faster and more informed decision-making in critical situations: AI analysis provides crucial data insights, allowing for faster and more informed decisions in critical situations, significantly improving response times.

- Reduced human error during emergency response: By automating certain tasks and providing real-time guidance, AI minimizes the potential for human error during high-pressure emergency response situations.

- Enhanced situational awareness through data visualization and AI-driven insights: AI-driven data visualization tools provide a clear and concise overview of the situation, enhancing situational awareness and improving decision-making capabilities.

Automated Safety Protocols

AI can automate safety protocols, ensuring consistent and reliable implementation of safety measures across all operations.

- Reduced reliance on human intervention, minimizing human error: Automation of safety protocols reduces the potential for human error, leading to more consistent and reliable safety practices.

- Consistent application of safety procedures across different operations: AI ensures that safety protocols are applied consistently across different operations and shifts, eliminating inconsistencies and improving overall safety.

- Increased efficiency and responsiveness in emergency situations: Automated safety protocols provide a faster and more efficient response during emergencies, improving overall safety outcomes.

- Enhanced compliance with industry regulations and safety standards: AI-driven automation helps ensure compliance with all relevant industry regulations and safety standards, minimizing risks and avoiding potential penalties.

The Future of Process Safety: Challenges and Opportunities

While the potential of AI in process safety is immense, several challenges need to be addressed for widespread adoption.

Data Security and Privacy

Protecting sensitive operational data is paramount. Robust cybersecurity measures are essential to safeguard against breaches and maintain data integrity.

Integration with Existing Systems

Seamless integration with existing legacy systems is crucial for successful implementation. Retrofitting older systems might require significant investment and planning.

Regulatory Compliance

Navigating the evolving regulatory landscape for AI-powered process safety systems will be vital for ensuring compliance and gaining acceptance.

Human-AI Collaboration

Successful implementation requires a collaborative approach, leveraging the strengths of both human expertise and AI capabilities. AI should augment human capabilities, not replace them.

Conclusion

This new patent application signals a paradigm shift in process safety, demonstrating the transformative potential of AI. By leveraging AI's capabilities for enhanced risk assessment, optimized safety procedures, and improved decision-making, the chemical and process industries can achieve unprecedented levels of safety and efficiency. This revolutionary technology promises to significantly reduce the risk of accidents, minimize downtime, and optimize operational costs. To learn more about how AI can revolutionize your process safety strategy, explore the latest advancements in AI-powered process safety solutions. Embrace the future of process safety and discover how AI can safeguard your operations.

Featured Posts

-

07 2025

Apr 30, 2025

07 2025

Apr 30, 2025 -

Amanda Owen Faces Emotional Turmoil Amidst Divorce From Clive

Apr 30, 2025

Amanda Owen Faces Emotional Turmoil Amidst Divorce From Clive

Apr 30, 2025 -

Boxing Skills Enhancement Seminar By Ace Power Promotion March 26th

Apr 30, 2025

Boxing Skills Enhancement Seminar By Ace Power Promotion March 26th

Apr 30, 2025 -

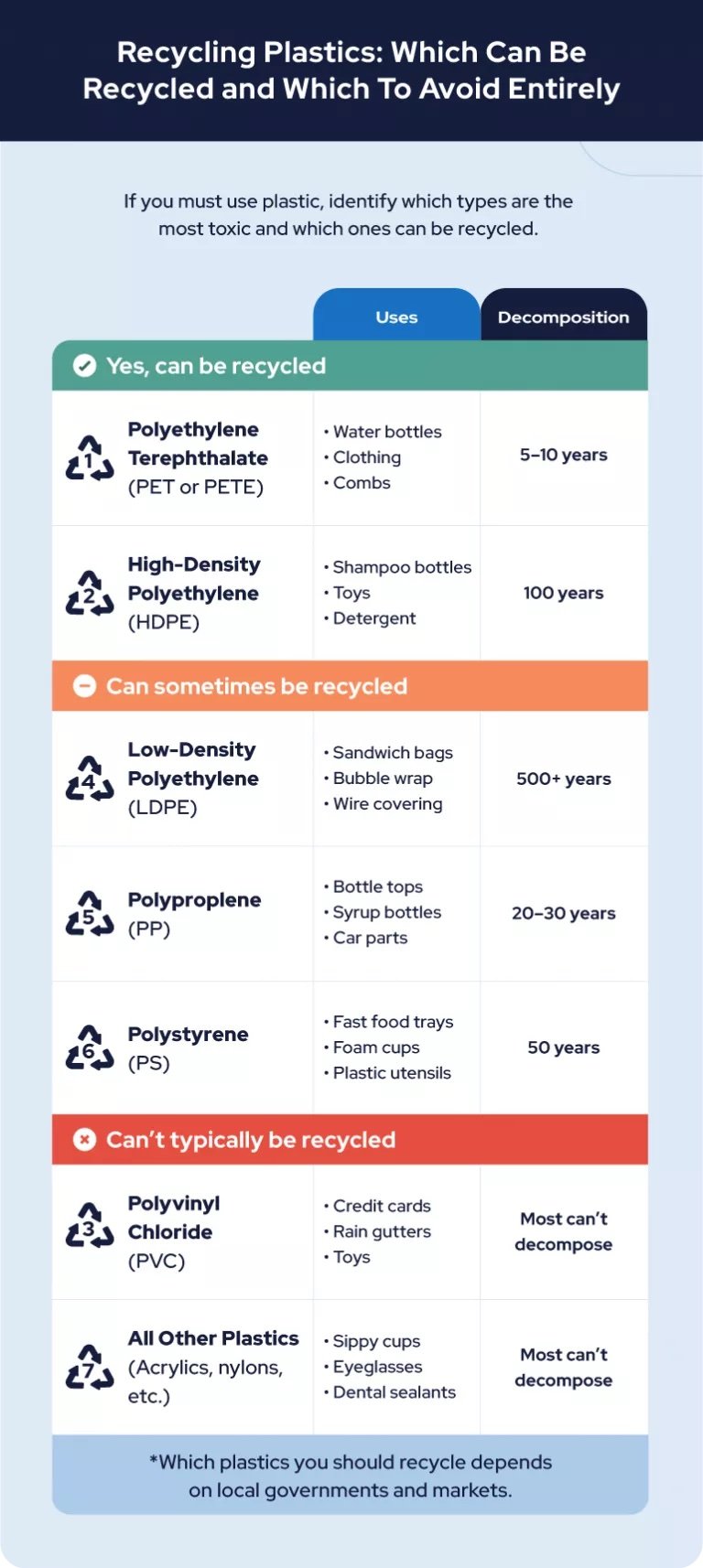

Are Your Household Plastics Harming Your Heart A Concerning New Study

Apr 30, 2025

Are Your Household Plastics Harming Your Heart A Concerning New Study

Apr 30, 2025 -

Investor Briefing Qnb Corp Presents On March 6th Virtual Conference

Apr 30, 2025

Investor Briefing Qnb Corp Presents On March 6th Virtual Conference

Apr 30, 2025