Overcoming The Challenges Of Robotic Nike Sneaker Assembly

Table of Contents

Precision and Dexterity Challenges in Robotic Sneaker Assembly

The intricate nature of sneaker construction presents a significant challenge for robotic automation. Unlike rigid components in other manufacturing sectors, sneakers involve flexible materials like leather and fabric, requiring precise movements and delicate handling. Traditional industrial robots, designed for heavy-duty tasks, often lack the necessary dexterity and precision for these nuanced operations. This is where the limitations of robotic dexterity become apparent.

- Difficulty in handling flexible materials: Fabric and leather are prone to wrinkling and tearing, requiring robots with advanced sensory feedback and adaptable grippers.

- Precise placement of components: Aligning laces, insoles, and other components with accuracy demands sophisticated robotic control and vision systems.

- Challenges in adapting to variations in shoe models and sizes: Sneaker designs vary significantly, requiring robots that can be quickly reprogrammed and adapted to handle different models and sizes.

- Need for advanced sensor technology and AI: Integrating advanced sensors and artificial intelligence (AI) is crucial for enhancing robotic dexterity and enabling robots to learn and adapt to the complexities of sneaker assembly. The development of flexible automation and adaptive robotics is key to overcoming these challenges.

Programming and Integration Complexity

Programming robots for the multifaceted tasks involved in sneaker assembly is extremely complex. It requires the development of sophisticated algorithms that accurately mimic the intricate movements of human hands. Furthermore, integrating various robotic systems and software platforms within an existing manufacturing infrastructure presents significant hurdles. This integration requires seamless communication and data flow between different components.

- Developing algorithms for complex assembly sequences: The sequential nature of sneaker assembly necessitates intricate algorithms that coordinate the actions of multiple robots.

- Integrating vision systems for accurate part recognition and placement: AI-powered vision systems are needed to identify and locate components accurately, ensuring proper placement during assembly.

- Managing data flow and communication between robots and other systems: Robust communication protocols are crucial to ensure that all robotic systems operate in sync and data is shared effectively.

- The need for skilled robotic programmers and engineers: Implementing and maintaining robotic systems requires a skilled workforce specialized in robotic programming and integration. The role of human-robot collaboration (HRC) is also becoming increasingly important in optimizing efficiency.

Cost and Return on Investment (ROI) of Robotic Sneaker Assembly

The initial investment in robotic systems for sneaker assembly can be substantial. This includes the cost of robots, associated infrastructure, and the skilled labor required for programming and maintenance. However, the potential long-term cost savings from increased efficiency and reduced labor costs can justify the investment. The ROI is heavily dependent on factors like production volume and the complexity of the shoe design.

- High initial capital expenditure for robots and associated infrastructure: This upfront investment can be significant, requiring careful financial planning.

- Costs of programming, integration, and maintenance: Ongoing expenses related to software updates, maintenance, and repairs must be factored into the total cost.

- Potential for reduced labor costs and increased output: Automation can lead to significant labor cost reductions while simultaneously increasing production volume.

- Faster production cycles and reduced lead times: Robotic systems can significantly reduce production cycle times, resulting in faster delivery of products.

Overcoming Challenges through Technological Advancements

Emerging technologies are playing a crucial role in addressing the challenges of robotic sneaker assembly. Collaborative robots (cobots), advanced sensor technology, and AI-powered vision systems are transforming the footwear manufacturing landscape.

- Cobots enabling safer and more flexible human-robot collaboration: Cobots allow humans and robots to work side-by-side, combining human dexterity with robotic precision.

- Improved sensor technology providing greater precision and dexterity: Advanced sensors enhance robots' ability to handle delicate materials and perform precise tasks.

- AI-powered vision systems for automated quality control: AI-driven vision systems can detect defects and ensure consistent product quality throughout the assembly process.

- Development of more adaptable and flexible robotic systems: New robotic systems are being designed with greater flexibility, allowing them to adapt to different shoe models and sizes more easily.

Conclusion

Robotic Nike sneaker assembly presents significant challenges related to precision, programming complexity, cost, and technological limitations. However, advancements in collaborative robots, AI, and sensor technology are progressively overcoming these hurdles. The long-term benefits – increased efficiency, reduced costs, improved product quality, and faster production cycles – are substantial. The future of automated shoe production hinges on continued innovation in this field. To stay ahead in this rapidly evolving industry, explore the latest advancements in robotic automation for footwear manufacturing. Engage with industry experts and delve deeper into the technologies discussed in this article to better understand the potential and challenges of robotic Nike sneaker assembly and its impact on the future of the footwear industry. The ongoing drive to overcome these challenges is paramount to meeting the ever-growing global demand for high-quality footwear.

Featured Posts

-

Covid 19 Test Fraud Lab Owner Admits To Falsifying Results

Apr 22, 2025

Covid 19 Test Fraud Lab Owner Admits To Falsifying Results

Apr 22, 2025 -

Strained Relations Examining The Breakdown Between The U S And China

Apr 22, 2025

Strained Relations Examining The Breakdown Between The U S And China

Apr 22, 2025 -

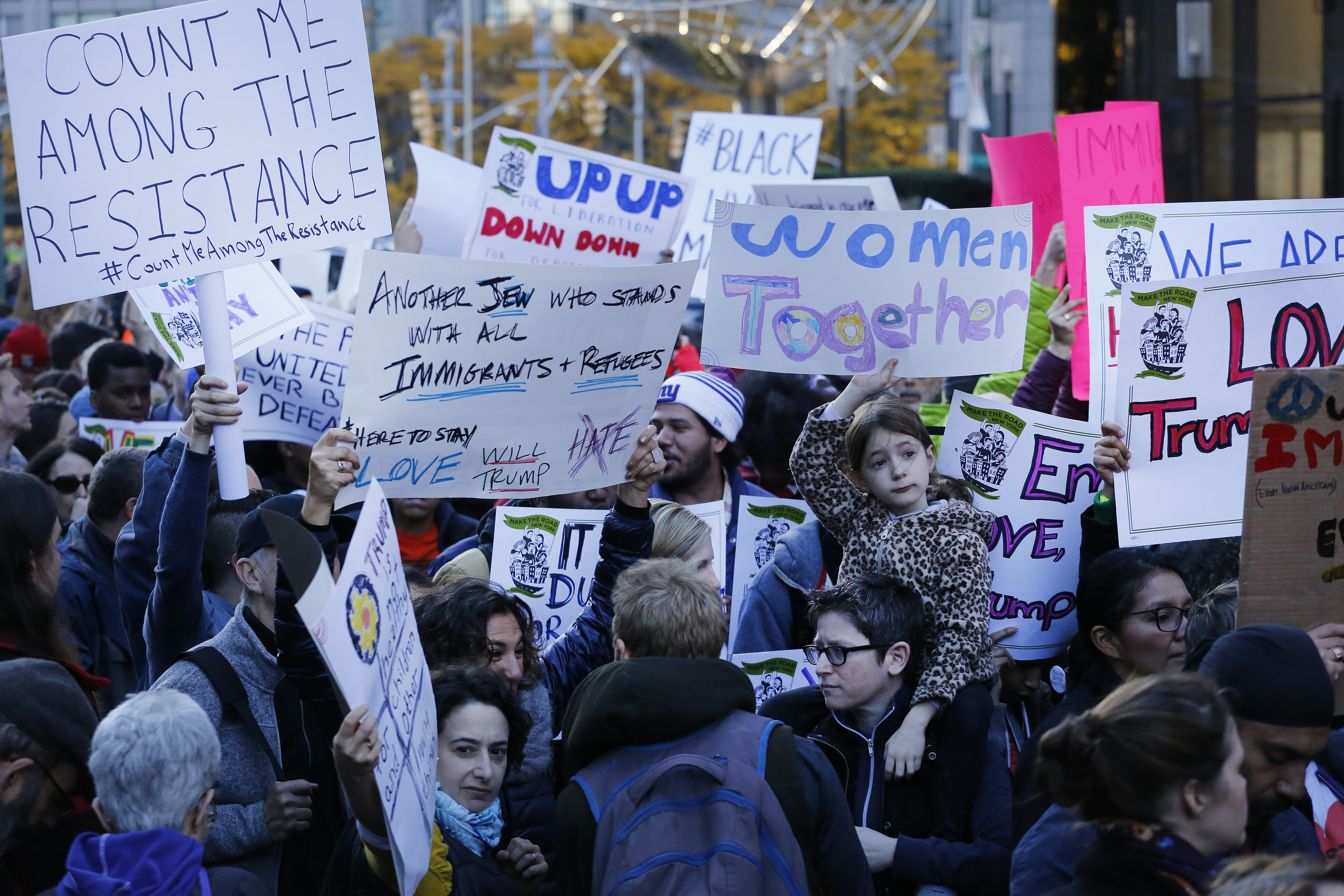

American Protests Examining The Anti Trump Movement

Apr 22, 2025

American Protests Examining The Anti Trump Movement

Apr 22, 2025 -

Nintendos Action Ryujinx Emulator Development Ceases

Apr 22, 2025

Nintendos Action Ryujinx Emulator Development Ceases

Apr 22, 2025 -

Ryujinx Emulator Shuts Down Following Nintendo Contact

Apr 22, 2025

Ryujinx Emulator Shuts Down Following Nintendo Contact

Apr 22, 2025