Orbital Space Crystals: Revolutionizing Pharmaceutical Drug Development

Table of Contents

Superior Crystal Growth in Microgravity

The microgravity environment of space offers unparalleled conditions for crystal growth, surpassing even the most advanced terrestrial methods. This superior growth is primarily due to the absence of gravity's influence.

Reduced Convection and Sedimentation

On Earth, gravity-driven convection currents and sedimentation disrupt crystal formation, leading to imperfections and reduced crystal size. In microgravity, these disruptive forces are minimized, allowing for the undisturbed growth of larger, more perfect crystals.

- Improved crystal homogeneity and uniformity: The absence of convection ensures uniform solute distribution, resulting in crystals with consistent properties throughout.

- Enhanced crystal size and morphology: Uninterrupted growth leads to significantly larger crystals with improved morphology, ideal for pharmaceutical applications.

- Reduced defects and impurities: The gentler growth process minimizes the incorporation of impurities and structural defects within the crystal lattice.

- Increased yield of high-quality crystals: Higher-quality crystals translate to higher yields of usable material, reducing waste and increasing efficiency.

Research from the International Space Station (ISS) has demonstrated the superior quality of protein crystals grown in microgravity. Studies on various pharmaceutical compounds, including specific examples like insulin and interferon, have shown significant improvements in crystal quality and size compared to Earth-grown counterparts. These findings highlight the potential of space-based crystal growth to enhance the development of various protein-based pharmaceuticals.

Enhanced Drug Purity and Efficacy

The superior crystal growth achieved in microgravity directly translates to enhanced drug purity and efficacy. Minimizing impurities and defects is crucial for optimizing drug performance and patient safety.

Minimized Impurities and Defects

The reduced convection and sedimentation in space result in crystals with significantly fewer impurities and structural defects compared to those grown on Earth. This improved purity has significant consequences:

- Improved bioavailability and absorption: Higher purity crystals are more readily absorbed by the body, leading to increased bioavailability and therapeutic effectiveness.

- Increased therapeutic efficacy: The absence of impurities enhances the drug's intended effects, maximizing its therapeutic potential.

- Reduced side effects: Higher purity translates to fewer adverse reactions, improving patient safety and tolerability.

- Longer shelf life: Reduced degradation due to impurities contributes to a longer shelf life, enhancing the drug's stability and reducing waste.

Studies have shown a direct correlation between increased crystal purity and improved patient outcomes. For instance, higher purity crystals can lead to a reduction in the required dosage, minimizing potential side effects and enhancing overall treatment efficacy. This translates to better patient experiences and improved healthcare outcomes.

Accelerated Drug Development and Cost Reduction

The improved crystal quality and increased yield facilitated by orbital space crystals can significantly reduce the time and resources required for drug development and manufacturing.

Streamlined Production Processes

The higher purity and larger size of space-grown crystals streamline downstream processing steps, reducing production costs and accelerating the overall drug development timeline.

- Faster drug approval processes: Higher-quality data from improved crystals can expedite regulatory approvals.

- Reduced production costs: Higher yields and reduced processing steps translate to lower manufacturing costs.

- Increased profitability for pharmaceutical companies: Efficiency gains translate to increased profits, incentivizing further investment in space-based crystal growth.

- Greater accessibility to life-saving medications: Lower production costs can improve accessibility to essential medications for patients worldwide.

The economic implications of faster drug development and reduced manufacturing costs are substantial. Reduced time-to-market for new drugs translates to earlier patient access to life-saving treatments, while lower production costs can make medications more affordable and accessible globally. The potential savings for healthcare systems are enormous.

Future Applications and Potential of Orbital Space Crystals

The advantages of orbital space crystals extend far beyond pharmaceutical applications. The technology holds immense promise for various industries.

Expanding Beyond Pharmaceuticals

The ability to grow high-quality crystals in microgravity has implications for diverse fields:

- Development of novel materials with unique properties: Space-grown crystals offer unique opportunities to develop advanced materials with tailored characteristics for various applications.

- Advancements in semiconductor technology: High-purity crystals are crucial for semiconductor manufacturing, and space-based growth could revolutionize this industry.

- Creation of high-precision optical components: Space-grown crystals could enable the creation of highly precise optical components for advanced technologies.

- Potential for space-based manufacturing facilities: The long-term vision involves establishing dedicated space-based facilities for crystal growth and manufacturing.

Ongoing research and collaboration between space agencies and pharmaceutical companies are exploring the full potential of this technology. Future advancements will likely lead to even more innovative applications and further revolutionize various high-tech industries.

Conclusion

Orbital space crystals offer a transformative approach to pharmaceutical drug development. The superior crystal quality, enhanced drug purity and efficacy, and accelerated development processes resulting from space-based crystal growth promise to revolutionize the industry. Explore the possibilities of orbital space crystals, invest in the future of drug development with orbital space crystals, and learn more about the groundbreaking advancements in orbital space crystals – together, we can unlock the full potential of this innovative technology to improve global healthcare.

Featured Posts

-

Grand Ole Opry Goes Global Historic London Concert

May 23, 2025

Grand Ole Opry Goes Global Historic London Concert

May 23, 2025 -

This Morning Cat Deeleys Phase Eight Midi Skirt Shoppers Cant Get Enough

May 23, 2025

This Morning Cat Deeleys Phase Eight Midi Skirt Shoppers Cant Get Enough

May 23, 2025 -

Un Nou Serial Netflix Cu O Distributie All Star Ce Asteptari Sa Avem

May 23, 2025

Un Nou Serial Netflix Cu O Distributie All Star Ce Asteptari Sa Avem

May 23, 2025 -

Vybz Kartels Travel Curtailed New Restrictions In Trinidad And Tobago

May 23, 2025

Vybz Kartels Travel Curtailed New Restrictions In Trinidad And Tobago

May 23, 2025 -

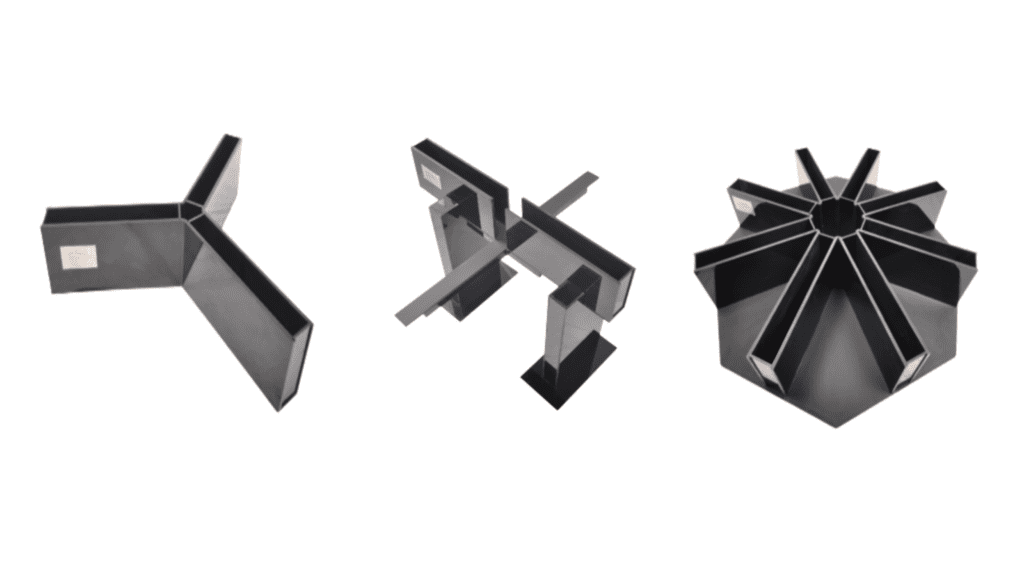

Bishop Englands Legacy Continues Two Grads Join Louisvilles 2025 Ncaa Tournament Bid

May 23, 2025

Bishop Englands Legacy Continues Two Grads Join Louisvilles 2025 Ncaa Tournament Bid

May 23, 2025

Latest Posts

-

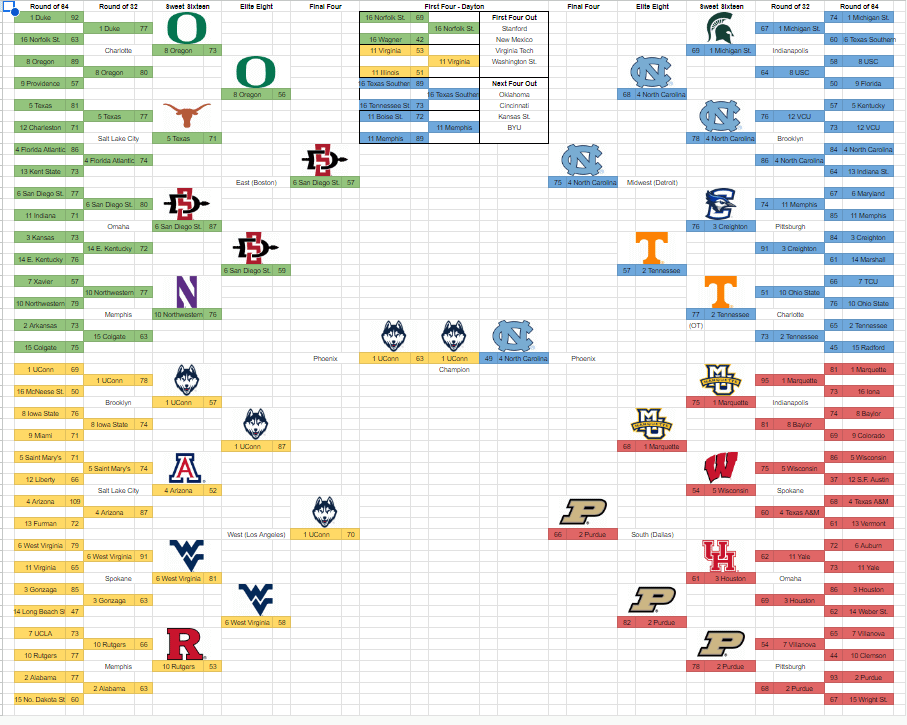

Nyt Mini Crossword Solution Marvels Avengers Clue Explained May 1st

May 23, 2025

Nyt Mini Crossword Solution Marvels Avengers Clue Explained May 1st

May 23, 2025 -

Marvels Avengers Crossword Clue Nyt Mini Crossword Answers For May 1st

May 23, 2025

Marvels Avengers Crossword Clue Nyt Mini Crossword Answers For May 1st

May 23, 2025 -

Nyt Mini Crossword Solutions March 13 Puzzle Solved

May 23, 2025

Nyt Mini Crossword Solutions March 13 Puzzle Solved

May 23, 2025 -

Nyt Mini Crossword March 13 2025 Complete Answers And Solutions

May 23, 2025

Nyt Mini Crossword March 13 2025 Complete Answers And Solutions

May 23, 2025 -

Nyt Mini Crossword Today Hints And Answers For March 3 2025

May 23, 2025

Nyt Mini Crossword Today Hints And Answers For March 3 2025

May 23, 2025