Increased Workboat Safety And Efficiency With TBS And Nebofleet's Automation

Table of Contents

Enhanced Safety Through Automation

Human error remains a leading cause of accidents in the workboat industry. Workboat automation, however, offers a powerful solution to mitigate these risks and create a safer working environment.

Reduced Human Error

Automation significantly minimizes human error, a major contributor to accidents. By automating critical tasks, we drastically reduce the potential for mistakes.

- Reduced risk of collisions: Advanced collision avoidance systems provide real-time alerts and automated responses, preventing potentially disastrous incidents.

- Improved navigation accuracy: Automated navigation systems enhance precision, reducing the likelihood of navigational errors.

- Automated safety checks: Systems automatically perform regular safety checks, ensuring compliance with regulations and identifying potential hazards proactively.

- Optimized load management: Automated load monitoring prevents overloading and ensures safe and stable cargo handling.

The integrated systems of TBS and Nebofleet offer comprehensive features like advanced radar integration and dynamic positioning, contributing significantly to reduced human error in navigation and vessel maneuvering. These features constantly monitor the vessel's surroundings and automatically adjust course or speed to prevent collisions, even in challenging weather conditions.

Improved Situational Awareness

Real-time data and monitoring are critical for effective emergency response. TBS and Nebofleet provide enhanced situational awareness, enabling quicker and more informed decisions.

- Remote monitoring capabilities: Operators can remotely monitor vessel performance and environmental conditions, providing a comprehensive overview even from afar.

- Real-time data dashboards: Intuitive dashboards present critical data points at a glance, allowing for immediate assessment of the situation.

- Improved communication systems: Integrated communication systems facilitate seamless information sharing among crew members and onshore personnel.

- Automated alerts for critical situations: The system automatically triggers alerts for critical events like equipment malfunctions, approaching storms, or potential collisions.

The integration of TBS and Nebofleet facilitates superior communication and data flow. This ensures that all stakeholders are aware of the vessel's status and any potential hazards, fostering faster and more coordinated responses to emergencies.

Increased Crew Wellbeing

Automating routine and physically demanding tasks reduces crew workload and fatigue, ultimately improving crew wellbeing and reducing human error caused by exhaustion.

- Automated tasks: Automation handles repetitive tasks, freeing up crew members for more critical duties.

- Improved ergonomics: Automation reduces physical strain associated with manual labor, leading to a more comfortable and safer work environment.

- Reduced physical strain: Automated systems handle heavy lifting and other strenuous tasks, mitigating the risk of injuries.

- Increased focus on safety protocols: Reduced workload allows crews to focus more on adhering to safety protocols and proactively identifying potential hazards.

By optimizing workflows and reducing physical demands, TBS and Nebofleet's automation features contribute to a safer and more comfortable working environment for crews, leading to improved morale and productivity.

Increased Efficiency with Automated Workboat Systems

Workboat automation doesn't just enhance safety; it significantly boosts operational efficiency, leading to cost savings and increased profitability.

Optimized Fuel Consumption

Automation enables more efficient route planning and vessel operation, resulting in significant fuel savings.

- Optimized speed and route calculations: Intelligent algorithms determine the most fuel-efficient routes, considering factors like weather conditions and current speed.

- Predictive maintenance to prevent fuel-wasting breakdowns: Automated systems monitor equipment performance and predict potential failures, enabling proactive maintenance and preventing costly downtime.

- Real-time fuel monitoring: Real-time fuel consumption data allows for continuous monitoring and optimization of fuel usage.

TBS and Nebofleet leverage advanced algorithms to analyze various factors and calculate the optimal speed and route for minimizing fuel consumption, reducing operational costs.

Streamlined Operations

Automation simplifies complex tasks, improving workflow and reducing operational downtime.

- Automated data logging: Automated data logging reduces the administrative burden and ensures accurate record-keeping.

- Simplified reporting: Automated reporting systems generate comprehensive reports, streamlining data analysis and decision-making.

- Remote diagnostics: Remote diagnostics facilitate quick troubleshooting and minimize downtime due to equipment malfunctions.

- Predictive maintenance scheduling: Predictive maintenance scheduling optimizes maintenance activities, preventing unexpected breakdowns and maximizing operational uptime.

For example, automated cargo handling systems streamline loading and unloading processes, reducing time and labor costs.

Enhanced Data Analysis and Reporting

Real-time data collection and analysis provide invaluable insights for continuous operational improvement.

- Improved decision-making: Data-driven insights support informed decisions, leading to better operational strategies.

- Identification of operational bottlenecks: Data analysis helps identify areas for improvement in workflow, optimizing efficiency.

- Predictive maintenance optimization: Data analysis refines predictive maintenance schedules, maximizing uptime and reducing maintenance costs.

- Cost savings analysis: Analyzing operational data provides a clear picture of cost savings achieved through automation.

The data gathered by TBS and Nebofleet allows operators to identify trends, predict future needs, and make data-driven decisions to further optimize their operations.

Conclusion

Implementing TBS and Nebofleet's automation solutions offers significant advantages for workboat operators, improving both safety and efficiency. Reduced human error, increased situational awareness, optimized fuel consumption, and streamlined operations are just some of the benefits. Workboat automation is a key factor in modernizing operations and securing a more sustainable and profitable future.

Call to Action: Invest in workboat automation today and experience the transformative impact of TBS and Nebofleet on your operations. Contact us to learn more about how our solutions can increase the safety and efficiency of your workboats. Explore the future of workboat automation and discover how it can significantly benefit your bottom line.

Featured Posts

-

Kashmirs Cat Owners In Upheaval Over Online Rumors

May 02, 2025

Kashmirs Cat Owners In Upheaval Over Online Rumors

May 02, 2025 -

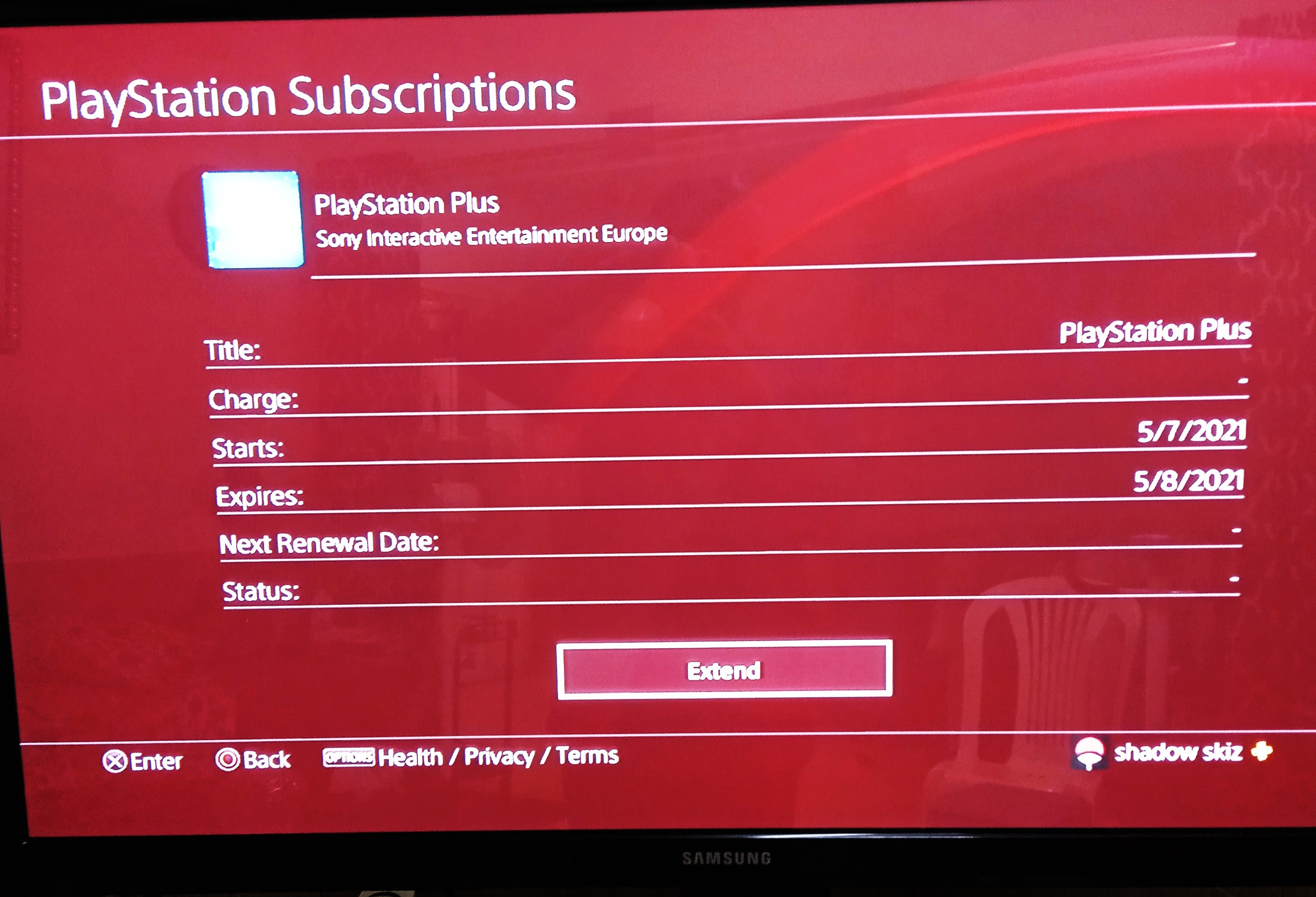

Play Station Christmas Voucher Glitch Sony Offers Free Credit To Affected Users

May 02, 2025

Play Station Christmas Voucher Glitch Sony Offers Free Credit To Affected Users

May 02, 2025 -

Veteran Actress Priscilla Pointer Dead At 100 A Legacy Remembered

May 02, 2025

Veteran Actress Priscilla Pointer Dead At 100 A Legacy Remembered

May 02, 2025 -

Us Vaccine Safety Under Scrutiny As Measles Cases Rise

May 02, 2025

Us Vaccine Safety Under Scrutiny As Measles Cases Rise

May 02, 2025 -

The State Of The Us Economy Under Biden Causes And Consequences

May 02, 2025

The State Of The Us Economy Under Biden Causes And Consequences

May 02, 2025

Latest Posts

-

Join The Sony Play Station Beta Program Details And Sign Up

May 02, 2025

Join The Sony Play Station Beta Program Details And Sign Up

May 02, 2025 -

Sony Compensates Play Station Users For Christmas Voucher Glitch With Free Credit

May 02, 2025

Sony Compensates Play Station Users For Christmas Voucher Glitch With Free Credit

May 02, 2025 -

New Play Station Beta Program Announced By Sony

May 02, 2025

New Play Station Beta Program Announced By Sony

May 02, 2025 -

Play Station Christmas Voucher Glitch Sony Offers Free Credit To Affected Users

May 02, 2025

Play Station Christmas Voucher Glitch Sony Offers Free Credit To Affected Users

May 02, 2025 -

Sony Play Station Beta Program What We Know So Far

May 02, 2025

Sony Play Station Beta Program What We Know So Far

May 02, 2025