Improving Automated Visual Inspection Systems For Lyophilized Vials

Table of Contents

Advanced Imaging Techniques for Lyophilized Vial Inspection

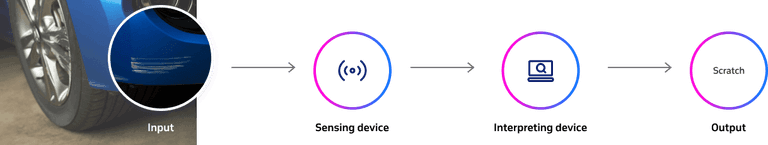

Traditional visual inspection methods often struggle to detect subtle defects in lyophilized vials. Advanced imaging techniques offer a significant improvement. High-resolution cameras capture detailed images, revealing cracks, chips, or particulate matter. Hyperspectral and multispectral imaging go further, analyzing the vial's contents across a range of wavelengths. This allows for the identification of subtle variations in cake appearance, such as inconsistencies in density or color, which might indicate compromised product quality.

- Improved contrast for defect detection: Advanced imaging techniques enhance contrast, making even minute defects easily visible.

- Ability to identify subtle variations in cake appearance: Hyperspectral and multispectral imaging provide detailed compositional information, revealing hidden defects.

- Reduced false positives: Sophisticated algorithms minimize misidentification of harmless variations as defects.

The integration of Artificial Intelligence (AI) and machine learning (ML) further enhances image analysis. AI algorithms can be trained to recognize specific defect patterns, leading to increased accuracy and reduced human intervention. These advancements overcome the limitations of traditional methods, providing a more comprehensive and reliable inspection process.

Optimizing Lighting and Image Acquisition

Consistent and appropriate lighting is crucial for optimal image quality in automated visual inspection. Poor lighting can lead to shadows, glare, and obscured defects, compromising the accuracy of the inspection.

- Minimizing shadows: Proper lighting techniques eliminate shadows that might mask defects.

- Eliminating glare: Careful control of light intensity and angle prevents glare from obscuring details.

- Optimizing light intensity and wavelength: Selecting the appropriate light intensity and wavelength enhances the visibility of specific defects.

Different lighting techniques, such as structured light and coaxial lighting, offer unique advantages. Structured light projects patterns onto the vial, creating a three-dimensional image that aids in defect detection. Coaxial lighting minimizes shadows by illuminating the vial from the same direction as the camera. Furthermore, optimizing image acquisition parameters, such as resolution and exposure time, is essential for achieving the desired level of detail and minimizing noise. Careful calibration and standardization of these parameters ensure consistent and reliable inspection results.

Robust Software Algorithms for Defect Detection and Classification

Sophisticated software algorithms are the heart of automated visual inspection systems. These algorithms analyze the acquired images, identify defects, and classify them according to severity.

- Use of machine learning for training and improved accuracy: Machine learning algorithms continuously learn and improve their defect detection capabilities.

- Implementation of advanced image processing techniques: Techniques like edge detection, filtering, and segmentation enhance image clarity and defect identification.

- Integration with existing quality control systems: Seamless integration streamlines workflows and facilitates data analysis.

The development of robust algorithms that minimize both false positives (incorrectly identifying a non-defect as a defect) and false negatives (missing actual defects) is paramount. Rigorous validation and testing are crucial to ensure the algorithms meet regulatory requirements and provide reliable inspection results. This ensures that only vials meeting the highest quality standards are released to the market.

Integration with Existing Manufacturing Processes and Data Management Systems

Seamless integration of automated visual inspection systems into existing pharmaceutical manufacturing lines is crucial for maximizing efficiency.

- Minimizing downtime: Careful planning and implementation minimize disruption to production.

- Maximizing throughput: Automated systems significantly increase inspection speed, boosting overall production.

- Real-time data analysis: Real-time feedback allows for immediate corrective action, preventing defective products from progressing through the production line.

- Data integration with ERP and MES systems: Integration with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) provides complete traceability and facilitates comprehensive data analysis.

Effective data management and traceability are essential for regulatory compliance. Automated systems provide detailed records of each inspection, facilitating audits and ensuring accountability. By automating the inspection process, pharmaceutical manufacturers can significantly improve overall efficiency, reduce labor costs, and enhance their overall quality control strategy.

The Future of Automated Visual Inspection for Lyophilized Vials

Improving automated visual inspection systems for lyophilized vials is not just about technological advancement; it's about ensuring patient safety and regulatory compliance. The key takeaways are the significant benefits of advanced imaging techniques, optimized lighting, robust software algorithms, and seamless integration for achieving high accuracy and efficiency in the inspection process. These improvements result in enhanced product quality, regulatory compliance, and cost reduction.

Investing in improving automated visual inspection systems for lyophilized vials is a strategic decision for pharmaceutical manufacturers. To stay competitive and ensure the highest quality standards, explore advanced solutions and technologies available today. Contact leading experts in automated visual inspection to discuss your specific needs and find optimized solutions for your manufacturing processes. Don't compromise on quality—invest in a future of enhanced efficiency and regulatory compliance through advanced automated visual inspection.

Featured Posts

-

Esta Adaptacao De Quadrinhos De Stallone Surpreendentemente Boa

May 12, 2025

Esta Adaptacao De Quadrinhos De Stallone Surpreendentemente Boa

May 12, 2025 -

Possible Successors To Pope Francis Examining Leading Contenders

May 12, 2025

Possible Successors To Pope Francis Examining Leading Contenders

May 12, 2025 -

Kloynei And Santler Sto Netflix I Tainia Jay Kelly Kai Oi Oskar Aspiries

May 12, 2025

Kloynei And Santler Sto Netflix I Tainia Jay Kelly Kai Oi Oskar Aspiries

May 12, 2025 -

Predicting The Next Pope Examining Potential Successors To The Papacy

May 12, 2025

Predicting The Next Pope Examining Potential Successors To The Papacy

May 12, 2025 -

Avestruz Ataca A Boris Johnson En Texas La Reaccion Del Exprimer Ministro

May 12, 2025

Avestruz Ataca A Boris Johnson En Texas La Reaccion Del Exprimer Ministro

May 12, 2025

Latest Posts

-

Which Rocky Movie Touches Stallone The Most His Answer Will Surprise You

May 12, 2025

Which Rocky Movie Touches Stallone The Most His Answer Will Surprise You

May 12, 2025 -

Sylvester Stallones Favorite Rocky Movie The Franchises Most Emotional Entry

May 12, 2025

Sylvester Stallones Favorite Rocky Movie The Franchises Most Emotional Entry

May 12, 2025 -

The One Movie Sylvester Stallone Directed But Didnt Star In A Critical And Commercial Failure

May 12, 2025

The One Movie Sylvester Stallone Directed But Didnt Star In A Critical And Commercial Failure

May 12, 2025 -

Action Thriller Armor Starring Sylvester Stallone Free Online Streaming

May 12, 2025

Action Thriller Armor Starring Sylvester Stallone Free Online Streaming

May 12, 2025 -

Sylvester Stallone Action Thriller Armor Now Streaming Free

May 12, 2025

Sylvester Stallone Action Thriller Armor Now Streaming Free

May 12, 2025