Expensive Offshore Wind: Challenges And Shifting Investment Priorities

Table of Contents

High Initial Capital Expenditure (CAPEX)

Developing offshore wind farms requires a substantial upfront investment. This high initial capital expenditure (CAPEX) is a major contributor to the overall cost and often leads to project delays or cancellations. Several factors contribute to this high CAPEX:

-

Expensive turbine technology and installation: Offshore wind turbines are significantly larger and more complex than their onshore counterparts, requiring specialized manufacturing processes and highly skilled installation crews. The sheer scale of these projects necessitates specialized vessels, increasing installation costs dramatically.

-

Complex grid connection infrastructure costs: Connecting offshore wind farms to the onshore electricity grid requires extensive subsea cabling and onshore substation upgrades, adding significant cost and complexity to the project. The distance from shore and the need for robust infrastructure to withstand harsh marine environments further inflate these costs.

-

Extensive site surveys and environmental impact assessments: Before construction can begin, thorough site surveys and environmental impact assessments are necessary to ensure the project’s ecological viability and compliance with regulations. These assessments are time-consuming and expensive, adding to the overall CAPEX.

-

Substantial permitting and regulatory hurdles: Navigating the complex permitting process often involves multiple regulatory bodies and stakeholders, leading to delays and increased costs. The lengthy approval process adds significantly to the project timeline and overall expenditure.

-

High labor costs due to specialized skills required: Offshore wind farm construction and maintenance require highly skilled workers with specialized training. The demand for these skilled professionals leads to high labor costs, adding to the overall project expense.

For example, the Vineyard Wind project off the coast of Massachusetts initially faced significant cost overruns due to challenges in grid connection and permitting delays. Understanding these cost drivers is crucial for future project planning and cost control.

Supply Chain Bottlenecks and Material Costs

The global supply chain disruptions of recent years have significantly impacted the cost of offshore wind projects. The increased demand for specialized materials and the challenges in logistics have resulted in significant price increases and project delays.

-

Increased demand for specialized materials (steel, rare earth magnets): The surge in demand for steel, rare earth magnets, and other critical materials used in wind turbine manufacturing has led to price volatility and shortages. This increased demand is further exacerbated by global supply chain disruptions, increasing material costs.

-

Port congestion and logistical challenges: Transporting large wind turbine components and other materials to offshore construction sites presents significant logistical challenges. Port congestion and limitations in handling large, specialized cargo further increase transportation costs.

-

Geopolitical factors impacting material availability and prices: Geopolitical instability and trade disputes can disrupt the supply of critical materials, leading to price increases and project uncertainties. The dependence on certain countries for specific materials makes offshore wind projects susceptible to geopolitical risk.

-

Manufacturing capacity limitations: The manufacturing capacity for large wind turbine components may not be able to keep up with the rapidly growing demand, leading to delays and increased costs. Expanding manufacturing capacity requires substantial investment and time.

-

Inflationary pressures on project costs: Inflationary pressures across all sectors have increased the cost of labor, materials, and services, further contributing to the high cost of offshore wind projects. The overall economic climate has a direct impact on the budget.

For instance, the shortage of rare earth magnets, crucial for wind turbine generators, has led to substantial cost increases and delays in several projects globally. Careful supply chain management and diversification of sourcing are essential to mitigate these risks.

Operational and Maintenance (OPEX) Costs

The ongoing operational and maintenance (OPEX) costs associated with offshore wind farms are also substantial, adding to the overall project lifecycle cost. The remote location and harsh marine environment pose unique challenges.

-

High cost of specialized vessels and equipment for maintenance: Accessing and maintaining offshore wind turbines requires specialized vessels and equipment, capable of operating in challenging weather conditions. The cost of chartering these specialized vessels and maintaining the equipment represents a significant portion of the OPEX.

-

Challenges related to accessibility and harsh weather conditions: The remote location and unpredictable weather conditions in offshore environments make maintenance and repairs difficult and costly. Downtime due to adverse weather further impacts project revenue.

-

Need for skilled technicians and ongoing training: Maintaining offshore wind farms requires highly skilled technicians with specialized training. The need for continuous training and development adds to the overall OPEX.

-

Regular component replacements and repairs: Offshore wind turbines are subject to wear and tear from the harsh marine environment, necessitating regular component replacements and repairs, adding to maintenance costs. Predictive maintenance techniques are being explored to minimize unscheduled downtime.

-

Environmental monitoring and mitigation costs: Regular environmental monitoring and mitigation efforts are required to ensure the project's ecological impact remains within acceptable limits. Compliance with environmental regulations adds to OPEX.

The remote location of offshore wind farms significantly increases maintenance costs compared to onshore wind farms. Innovative maintenance strategies and technological advancements are crucial to reduce these expenses.

Shifting Investment Priorities and Mitigation Strategies

The high cost of offshore wind is influencing investment decisions, driving a shift towards strategies focused on cost optimization and risk mitigation.

-

Increased focus on project risk management and cost optimization: Investors are increasingly prioritizing thorough risk assessment and cost optimization strategies to minimize project uncertainties and reduce overall costs. Detailed project planning and rigorous cost control measures are becoming critical.

-

Exploration of alternative financing models (e.g., public-private partnerships): Alternative financing models, such as public-private partnerships, are gaining traction to leverage the expertise and resources of both public and private sectors, mitigating financial risks. Government incentives and guarantees can attract private investment.

-

Technological advancements to reduce CAPEX and OPEX (e.g., floating offshore wind): Technological advancements, such as floating offshore wind technology, are being explored to reduce costs associated with installation and maintenance in deeper waters. Innovation is key to making offshore wind more competitive.

-

Government subsidies and policy support to incentivize development: Government subsidies, tax incentives, and supportive policies are crucial for incentivizing offshore wind development and reducing project costs. Stable and predictable regulatory environments are essential for attracting investors.

-

Emphasis on improving efficiency and reducing permitting times: Streamlining the permitting process and improving project efficiency through better planning and execution can significantly reduce project costs and delays. Collaboration between stakeholders and improved regulatory processes are critical.

Governments are increasingly recognizing the importance of investing in offshore wind energy and are introducing policies and incentives to make it more competitive. For instance, many countries offer tax credits and feed-in tariffs to incentivize offshore wind development.

Conclusion

The high cost of offshore wind, driven by factors like high CAPEX, supply chain issues, and substantial OPEX, presents a significant challenge for the renewable energy sector. However, shifts in investment priorities toward risk mitigation, technological innovation, and supportive government policies offer hope for a more cost-effective future. To fully realize the potential of offshore wind power, continued focus on reducing the overall cost and improving project efficiency is crucial. Understanding the challenges surrounding expensive offshore wind is essential for stakeholders to make informed decisions and drive progress towards a sustainable energy future. Explore potential solutions and contribute to the discussion on how to make offshore wind more affordable and accessible.

Featured Posts

-

The Unpredictability Of Trumps Tariffs An Automotive Industry Perspective

May 03, 2025

The Unpredictability Of Trumps Tariffs An Automotive Industry Perspective

May 03, 2025 -

Le Vatican Temoin D Une Conversation Houleuse Entre Trump Et Macron

May 03, 2025

Le Vatican Temoin D Une Conversation Houleuse Entre Trump Et Macron

May 03, 2025 -

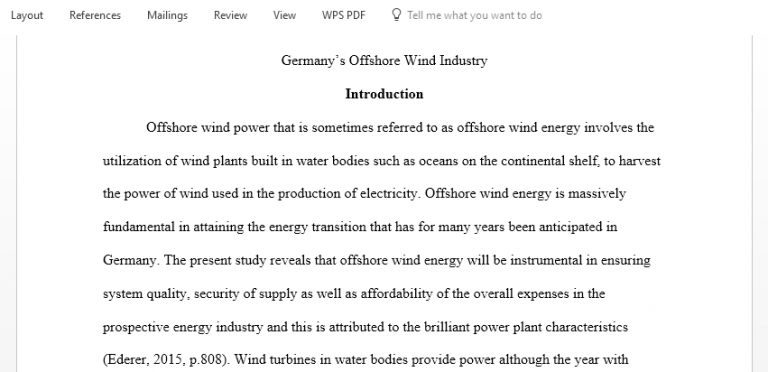

Fotos Laura Keller Em Retiro De Tantra Yoga De Biquini

May 03, 2025

Fotos Laura Keller Em Retiro De Tantra Yoga De Biquini

May 03, 2025 -

Ps 5 Gets Retro Sony Brings Back Beloved Console Themes

May 03, 2025

Ps 5 Gets Retro Sony Brings Back Beloved Console Themes

May 03, 2025 -

Lee Anderson Accuses Rupert Lowe Civil War Threatens Conservative Party Unity

May 03, 2025

Lee Anderson Accuses Rupert Lowe Civil War Threatens Conservative Party Unity

May 03, 2025