Electric Motor Innovation: A Path To Reducing China's Dominance

Table of Contents

Technological Advancements in Electric Motor Design

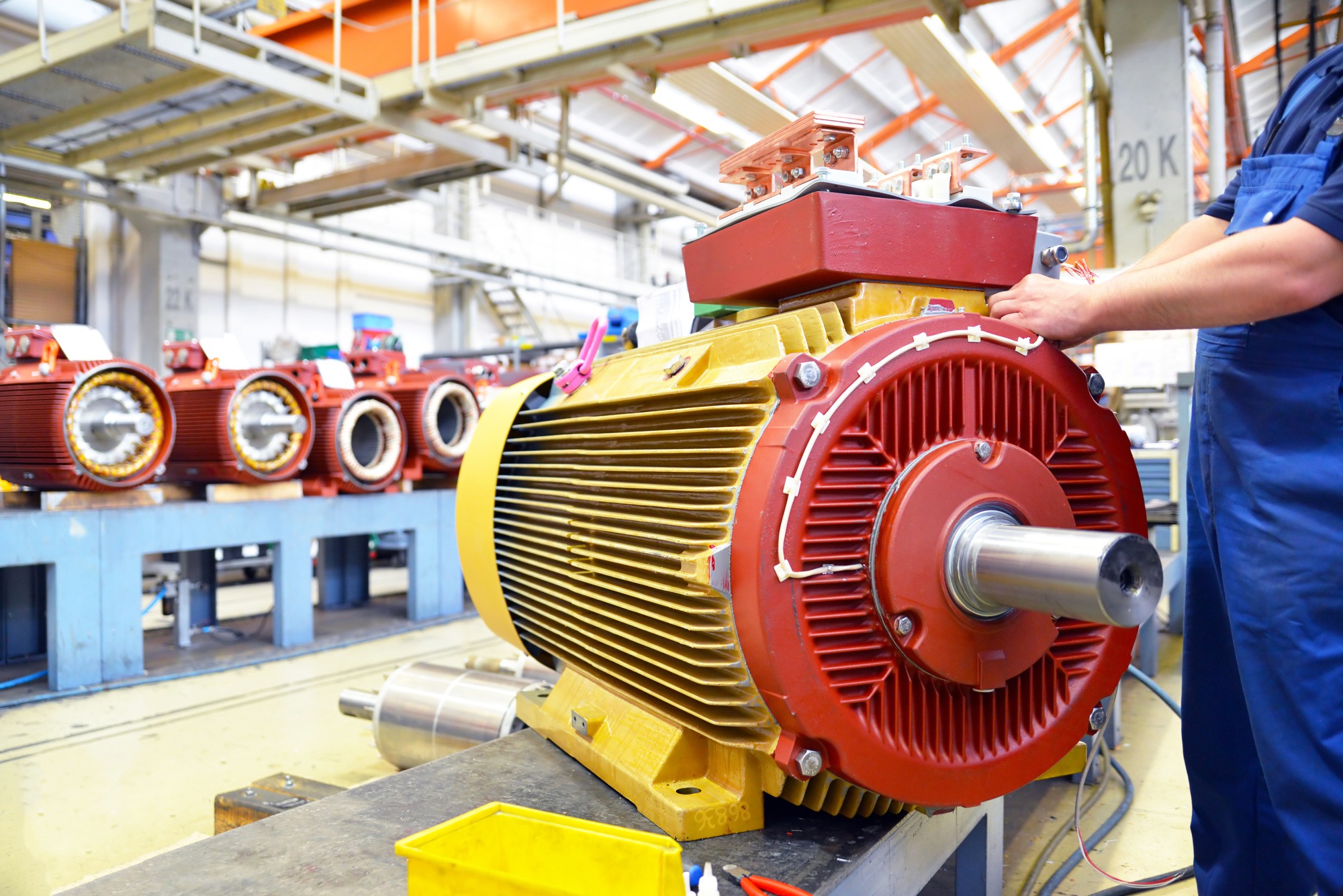

To break China's hold on the electric motor market, significant advancements in electric motor design are crucial. This involves improving efficiency, performance, and reducing reliance on materials sourced predominantly from China.

High-Efficiency Motor Designs

Improving energy efficiency is paramount. Advancements in magnet technology are key to achieving this. The current reliance on rare-earth magnets, primarily sourced from China, needs to be addressed.

- Developments in permanent magnet synchronous motors (PMSM): Research focuses on improving the efficiency and power density of PMSMs while reducing the amount of rare-earth materials needed. This includes exploring alternative magnet materials and optimizing motor geometries.

- Advancements in switched reluctance motors (SRM): SRMs offer a potential solution by eliminating the need for permanent magnets altogether, thus sidestepping the rare-earth dependence. Research is ongoing to improve their efficiency and controllability.

- Optimizing induction motors (IM): While less efficient than PMSMs, IMs are simpler and less reliant on rare-earth materials. Improvements in their design and control strategies are crucial for enhancing their competitiveness.

- Research into novel materials and manufacturing processes: This includes exploring new magnetic materials, advanced winding techniques, and innovative manufacturing processes such as additive manufacturing (3D printing) to improve motor performance and reduce manufacturing costs.

Power Electronics Integration

Power electronics play a vital role in optimizing electric motor performance and efficiency. Integrating advanced power electronics is critical for maximizing energy savings and minimizing losses.

- Development of SiC and GaN-based power electronics: Silicon carbide (SiC) and gallium nitride (GaN) semiconductors offer significantly higher switching frequencies and lower energy losses compared to traditional silicon-based devices. Their adoption is key to improving motor efficiency.

- Advanced motor control algorithms and digital signal processing techniques: Real-time optimization of motor control using sophisticated algorithms and digital signal processing can significantly improve efficiency and performance, reducing energy waste and maximizing output.

Diversifying the Global Supply Chain

Reducing China's dominance requires a deliberate effort to diversify the global electric motor supply chain. This involves strategic partnerships, investments, and reshoring initiatives.

Strategic Partnerships and Investments

International collaboration and investment are crucial for fostering innovation hubs outside of China.

- Incentivize the establishment of new manufacturing facilities: Governments should offer incentives to companies willing to establish electric motor manufacturing facilities in countries with strong technological capabilities and supportive regulatory environments.

- Support the development of robust local supply chains: This includes investing in the mining, processing, and manufacturing of critical materials and components needed for electric motor production, reducing reliance on single-source suppliers.

Reshoring and Nearshoring Initiatives

Bringing electric motor manufacturing back to home countries or relocating it to nearby regions can reduce reliance on long and vulnerable supply chains.

- Government policies and financial incentives: Governments can play a significant role in supporting reshoring and nearshoring efforts through tax breaks, grants, and other financial incentives.

- Focus on automation and advanced manufacturing techniques: Adopting automation and advanced manufacturing technologies can enhance competitiveness and reduce labor costs, making reshoring and nearshoring more attractive.

Focus on Sustainable and Ethical Sourcing

Sustainable and ethical sourcing practices are essential for building a responsible and resilient electric motor industry.

Reducing Reliance on Rare-Earth Minerals

Minimizing or eliminating the need for rare-earth elements is critical to reduce dependence on China.

- Exploration of alternative materials: This includes investigating alternative magnet materials such as ferrite magnets and developing advanced magnetic materials that offer similar performance with reduced rare-earth content.

- Development of recycling processes: Developing efficient and cost-effective recycling processes for rare-earth materials is essential for enhancing sustainability and reducing environmental impact.

Promoting Ethical and Responsible Manufacturing

Ethical labor practices and environmental protection are paramount throughout the supply chain.

- Implementation of strict ESG standards: Companies should implement and adhere to stringent environmental, social, and governance (ESG) standards throughout their supply chains.

- Transparency and traceability: Ensuring transparency and traceability in the sourcing of materials and components helps to identify and address any ethical or environmental concerns.

Conclusion

Reducing China's dominance in the electric motor market necessitates a multi-pronged approach encompassing technological breakthroughs, strategic supply chain diversification, and a commitment to ethical and sustainable sourcing. By investing in cutting-edge research and development of electric motor technology, fostering international collaborations, and implementing robust policies, we can create a more resilient and globally distributed electric motor industry. The future of clean energy and technological independence hinges on accelerating electric motor innovation. Let's actively pursue these strategies to create a more balanced and secure global landscape for electric motor technology, ensuring a sustainable and responsible future for this vital industry.

Featured Posts

-

Bob Bafferts Kentucky Derby Return An Identity Crisis In Racing

May 04, 2025

Bob Bafferts Kentucky Derby Return An Identity Crisis In Racing

May 04, 2025 -

Netherlands Hosts Lion Storages 1 4 G Wh Bess Project Financial Close Achieved

May 04, 2025

Netherlands Hosts Lion Storages 1 4 G Wh Bess Project Financial Close Achieved

May 04, 2025 -

The Rise Of Disaster Betting Examining The Case Of The Los Angeles Wildfires

May 04, 2025

The Rise Of Disaster Betting Examining The Case Of The Los Angeles Wildfires

May 04, 2025 -

Nhl Standings Crucial Friday Matchups And Playoff Scenarios

May 04, 2025

Nhl Standings Crucial Friday Matchups And Playoff Scenarios

May 04, 2025 -

Does Googles Search Ai Still Use Your Content After Opt Out

May 04, 2025

Does Googles Search Ai Still Use Your Content After Opt Out

May 04, 2025

Latest Posts

-

Nhl Standings And Showdown Saturday Key Matchups To Watch

May 04, 2025

Nhl Standings And Showdown Saturday Key Matchups To Watch

May 04, 2025 -

Showdown Saturday Nhl Playoffs Crucial Games And Standings Update

May 04, 2025

Showdown Saturday Nhl Playoffs Crucial Games And Standings Update

May 04, 2025 -

Nhl Playoffs Showdown Saturday A Look At The Standings

May 04, 2025

Nhl Playoffs Showdown Saturday A Look At The Standings

May 04, 2025 -

Johnston And Rantanen Lead Avalanche To Victory Over Panthers In High Scoring Affair

May 04, 2025

Johnston And Rantanen Lead Avalanche To Victory Over Panthers In High Scoring Affair

May 04, 2025 -

Showdown Saturday A Look At The Tight Nhl Playoff Standings Race

May 04, 2025

Showdown Saturday A Look At The Tight Nhl Playoff Standings Race

May 04, 2025