Electric Motor Innovation: A Path To China-Independent Supply Chains

Table of Contents

Technological Advancements Driving Independence

The path to breaking free from China's dominance begins with significant leaps in electric motor technology. Several key advancements are paving the way for a more diverse and secure global supply chain.

Next-Generation Motor Designs

The future of electric motor technology lies in innovative designs offering superior performance and reduced reliance on critical materials sourced from China. This includes advancements in:

- Permanent Magnet Motors (PMMs): While currently reliant on rare-earth magnets, research focuses on reducing this dependence through the development of high-performance alternative magnets and improved magnet utilization. This leads to enhanced efficiency and power density.

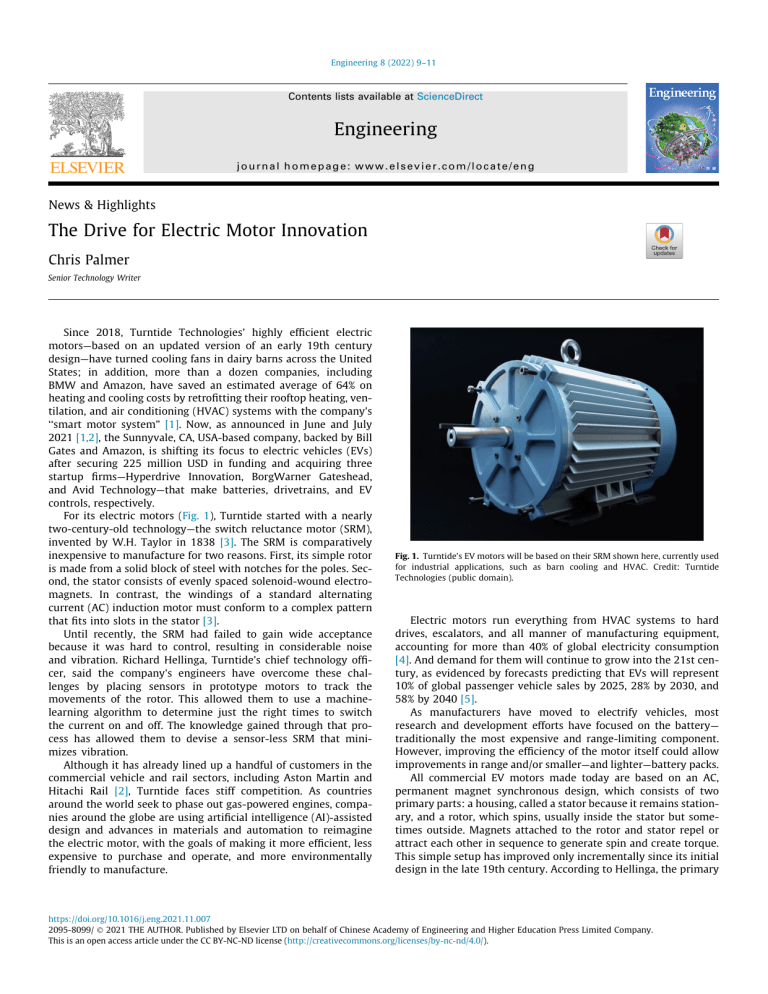

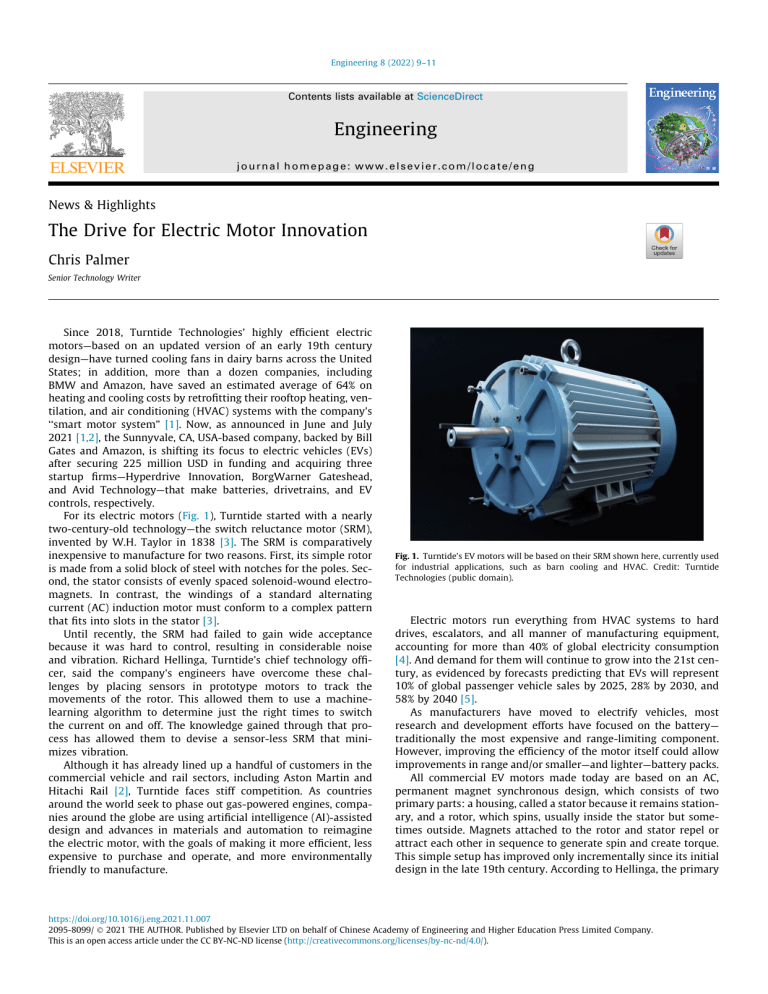

- Switched Reluctance Motors (SRMs): These motors offer a compelling alternative, eliminating the need for rare-earth magnets altogether. Advancements are focused on improving torque ripple and efficiency to match or surpass PMMs in specific applications.

- Axial Flux Motors: Characterized by their flat and compact design, these motors offer increased torque and power density in a smaller package, making them ideal for electric vehicles and other space-constrained applications.

These advancements translate into tangible benefits:

- Increased power output with reduced size: Leading to smaller, lighter, and more efficient systems.

- Improved thermal management: Enabling higher power densities and extended motor lifespan.

- Enhanced durability and lifespan: Reducing maintenance needs and overall lifecycle costs.

Advanced Materials and Manufacturing Processes

The development and adoption of novel materials and manufacturing processes are crucial for enhancing motor performance and reducing reliance on imported components. This includes:

- Advanced Composites: Lightweight and high-strength composite materials can replace heavier metal components, improving efficiency and reducing overall weight.

- High-Temperature Alloys: These materials allow for higher operating temperatures, leading to increased power density and efficiency.

- Additive Manufacturing (3D Printing): This technology enables the creation of complex motor designs with intricate internal geometries, optimizing performance and reducing material waste.

- Precision Machining: Advanced machining techniques ensure tight tolerances and improved surface finishes, leading to increased motor efficiency and durability.

The benefits are clear:

- Reduction in reliance on imported materials: Strengthening supply chain security and reducing geopolitical risks.

- Improved motor performance: Leading to higher efficiency, power density, and extended lifespan.

- Faster prototyping and production: Accelerating the development and deployment of new motor designs.

Intelligent Control and Power Electronics

Optimizing motor efficiency and performance requires advancements in control algorithms and power electronics. This includes:

- Advanced Control Algorithms: Sophisticated algorithms optimize motor operation, maximizing efficiency and minimizing energy loss.

- AI-Powered Motor Control Systems: Artificial intelligence enables predictive maintenance and real-time optimization of motor performance, further improving efficiency and reliability.

- Wide Bandgap Semiconductor Devices: Utilizing Silicon Carbide (SiC) and Gallium Nitride (GaN) offers improved power conversion efficiency and reduced energy losses.

Key advantages include:

- Improved motor efficiency and reliability: Reducing energy consumption and maintenance costs.

- Reduced energy consumption: Contributing to environmental sustainability and lower operating expenses.

- Predictive maintenance capabilities: Reducing downtime and extending the lifespan of motor systems.

Strategic Initiatives for Supply Chain Diversification

Technological advancements alone are insufficient; a comprehensive strategic approach is necessary to diversify supply chains and reduce reliance on China.

Government Policies and Incentives

Government intervention plays a critical role in fostering domestic electric motor manufacturing. This includes:

- Research grants and subsidies: Funding R&D efforts to accelerate technological innovation.

- Tax incentives for domestic production: Encouraging investment in domestic manufacturing facilities.

- Regulatory support for technology adoption: Creating a favorable environment for the adoption of new technologies.

Examples of successful initiatives include government-backed research consortia and targeted investment programs focused on specific electric motor technologies.

Collaboration and Partnerships

Success requires collaboration between industry, academia, and research institutions:

- Joint research initiatives: Pooling resources and expertise to accelerate technological breakthroughs.

- Technology transfer agreements: Facilitating the transfer of knowledge and technology between research institutions and industry.

- Shared resources and facilities: Optimizing the use of expensive equipment and infrastructure.

Successful collaborative projects often lead to faster innovation and the development of more competitive electric motor technologies.

Reshoring and Regionalization

Reshoring and regionalizing production is vital for building resilient supply chains:

- Reduced transportation costs and lead times: Leading to faster delivery and reduced inventory costs.

- Improved supply chain visibility and control: Reducing disruptions and improving responsiveness to market changes.

- Enhanced national security: Reducing reliance on foreign suppliers and strengthening national self-sufficiency.

Numerous companies are successfully reshoring production, demonstrating the tangible benefits of this strategy.

Conclusion

Electric motor innovation is crucial for building secure and resilient supply chains independent of China. By investing in next-generation motor designs, advanced materials, intelligent control systems, and fostering strategic collaborations, nations can drastically reduce their dependence on a single source for this critical technology. The path to China-independent supply chains necessitates a multifaceted approach encompassing technological advancements, supportive government policies, and robust industry partnerships. Embracing electric motor innovation is key to achieving long-term technological independence and ensuring a secure future for diverse industries. Let's accelerate the development and adoption of innovative electric motor solutions to create truly independent and resilient supply chains.

Featured Posts

-

Canadas Economic Future Gary Mar Advocates For Western Investment And Growth

May 05, 2025

Canadas Economic Future Gary Mar Advocates For Western Investment And Growth

May 05, 2025 -

Is Stefano Domenicali Responsible For Formula 1s Explosive Growth

May 05, 2025

Is Stefano Domenicali Responsible For Formula 1s Explosive Growth

May 05, 2025 -

Kentucky Derby 151 Countdown Your Guide To Race Day

May 05, 2025

Kentucky Derby 151 Countdown Your Guide To Race Day

May 05, 2025 -

Christian Horner On Max Verstappen Becoming A Dad A Quip

May 05, 2025

Christian Horner On Max Verstappen Becoming A Dad A Quip

May 05, 2025 -

Will Big Oil Increase Production Opec Meeting In Focus

May 05, 2025

Will Big Oil Increase Production Opec Meeting In Focus

May 05, 2025

Latest Posts

-

Inside Paddy Pimbletts Post Fight Yacht Party Following Ufc 314

May 05, 2025

Inside Paddy Pimbletts Post Fight Yacht Party Following Ufc 314

May 05, 2025 -

Paddy Pimbletts Dominant Win At Ufc 314 Leads To Private Yacht Celebration

May 05, 2025

Paddy Pimbletts Dominant Win At Ufc 314 Leads To Private Yacht Celebration

May 05, 2025 -

Ufc 314 Winner Paddy Pimblett Throws Lavish Yacht Party

May 05, 2025

Ufc 314 Winner Paddy Pimblett Throws Lavish Yacht Party

May 05, 2025 -

Paddy Pimbletts Post Ufc 314 Yacht Party Exclusive Details

May 05, 2025

Paddy Pimbletts Post Ufc 314 Yacht Party Exclusive Details

May 05, 2025 -

Ufc 314 What To Expect From The Volkanovski Vs Lopes Main Event

May 05, 2025

Ufc 314 What To Expect From The Volkanovski Vs Lopes Main Event

May 05, 2025