Challenges And Advancements In Automated Lyophilized Vial Inspection

Table of Contents

Challenges in Automated Lyophilized Vial Inspection

Automated lyophilized vial inspection presents several significant hurdles that manufacturers must overcome to ensure product quality and regulatory compliance. These challenges span visual inspection difficulties, technological limitations, and the stringent requirements of regulatory compliance and validation.

Visual Inspection Difficulties

Even for trained inspectors, visually identifying subtle defects in lyophilized vials is extremely challenging. These defects can include:

- Cracks: Microscopic cracks in the glass can compromise vial integrity and lead to leakage or contamination.

- Particulate Matter: Small particles within the vial can negatively impact drug efficacy and safety.

- Fill Level Variations: Inconsistent fill levels can indicate issues with the lyophilization process or filling equipment.

High variability in vial appearance makes consistent visual inspection difficult. Human error is a significant factor, with fatigue leading to decreased accuracy and increased oversight of critical defects. The time-consuming nature of manual inspection further exacerbates the problem, especially given the increasing demand for higher throughput in pharmaceutical manufacturing. Distinguishing between acceptable variations in vial appearance and critical defects often requires significant expertise and experience, making consistent, accurate manual inspection a major challenge.

Technological Limitations

The very nature of lyophilized vials and the freeze-drying process creates significant technological hurdles for automated inspection systems. These include:

- Suboptimal Image Acquisition: The geometry of vials, combined with the often-transparent nature of the glass, makes consistent and high-quality image acquisition difficult. Variations in lighting, reflections, and the three-dimensional nature of the vials further complicate the process.

- Handling Variability: Automated systems must be capable of handling a range of vial sizes and shapes without compromising image quality or throughput. This requires sophisticated robotic handling systems and adaptable image processing algorithms.

- Inconsistent Image Quality: Variations in image quality directly impact the performance of image processing algorithms. Inconsistent lighting, reflections, and shadows can lead to inaccurate defect detection and classification.

These technological challenges often require advanced image processing techniques and sophisticated algorithms to overcome, increasing the complexity and cost of automated inspection systems.

Regulatory Compliance and Validation

Meeting regulatory requirements for automated lyophilized vial inspection systems is a significant challenge. Stringent guidelines from agencies like the FDA and EMA necessitate:

- Rigorous Validation Protocols: Comprehensive validation protocols are required to demonstrate the accuracy, precision, and reliability of the automated system. This often involves extensive testing and documentation.

- Data Integrity: Ensuring the integrity and traceability of inspection data is crucial for regulatory compliance. This requires robust data management systems and audit trails.

- Costly and Time-Consuming Processes: The validation process itself is costly and time-consuming, requiring significant investment in resources and expertise.

The high cost and complexity of regulatory compliance contribute significantly to the overall cost of implementing automated lyophilized vial inspection systems.

Advancements in Automated Lyophilized Vial Inspection

Despite the significant challenges, advancements in imaging technologies, image processing algorithms, and integrated automation solutions are revolutionizing automated lyophilized vial inspection.

Improved Imaging Technologies

Several advanced imaging techniques are improving the accuracy and sensitivity of defect detection in lyophilized vials:

- Multispectral Imaging: Utilizes multiple wavelengths of light to enhance the contrast between defects and the vial itself, improving the detection of subtle cracks or particulate matter.

- Hyperspectral Imaging: Captures a continuous spectrum of light, providing even more detailed information about the vial's composition and surface features, enabling more precise defect identification.

- 3D Imaging: Provides a three-dimensional representation of the vial, allowing for the detection of defects that may be hidden or difficult to see in two-dimensional images.

These advanced imaging techniques significantly improve image clarity and sensitivity, allowing for the detection of defects previously missed by traditional methods.

Advanced Image Processing Algorithms

Artificial intelligence (AI) and machine learning (ML) are playing a critical role in advancing automated lyophilized vial inspection:

- AI-Powered Defect Detection: AI algorithms can learn to identify defects based on vast datasets of images, significantly improving the accuracy and speed of inspection.

- Adaptive Algorithms: These algorithms can adapt to variations in vial appearance and lighting conditions, improving robustness and reducing the need for manual adjustments.

- Enhanced Data Analysis: AI provides advanced data analysis capabilities, allowing manufacturers to identify trends and improve their manufacturing processes.

The use of AI and ML is leading to a significant reduction in false positives and false negatives, improving the overall accuracy and efficiency of automated lyophilized vial inspection systems.

Integrated Automation Solutions

The integration of robotic systems is streamlining the entire inspection process:

- Automated Handling: Robots automate the handling, feeding, and sorting of vials, increasing throughput and efficiency.

- Seamless Integration: Automated systems can be seamlessly integrated with other manufacturing processes, creating a fully automated production line.

- Improved Traceability: Automated systems provide enhanced traceability, simplifying regulatory compliance and facilitating recall management.

The integration of robotics and advanced automation technologies is significantly reducing labor costs and improving overall efficiency in the pharmaceutical manufacturing process.

Conclusion

Automated Lyophilized Vial Inspection is crucial for maintaining high-quality pharmaceutical products. While challenges exist in effectively inspecting lyophilized vials due to visual complexities and regulatory constraints, significant advancements in imaging technologies and AI-powered algorithms are revolutionizing this field. By adopting these innovative solutions, manufacturers can enhance the accuracy, efficiency, and compliance of their inspection processes, ultimately contributing to safer and more effective medications. Investing in advanced Automated Lyophilized Vial Inspection systems is not just a technological upgrade; it’s a strategic step towards ensuring product quality and patient safety. Explore the latest advancements in automated lyophilized vial inspection today and optimize your pharmaceutical manufacturing process.

Featured Posts

-

To Netflix Jay Kelly Kloynei Santler Kai I Poreia Gia Oskar

May 12, 2025

To Netflix Jay Kelly Kloynei Santler Kai I Poreia Gia Oskar

May 12, 2025 -

Knicks Vs Cavaliers How To Watch The Game Live Tv Listings And Streaming Details

May 12, 2025

Knicks Vs Cavaliers How To Watch The Game Live Tv Listings And Streaming Details

May 12, 2025 -

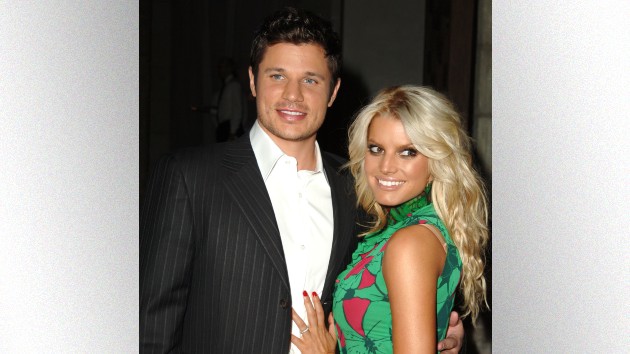

Navigating Heartbreak Jessica Simpsons Journey Through Past Relationships

May 12, 2025

Navigating Heartbreak Jessica Simpsons Journey Through Past Relationships

May 12, 2025 -

Uruguay El Significado De Semana De Turismo Y Su Contexto Cultural

May 12, 2025

Uruguay El Significado De Semana De Turismo Y Su Contexto Cultural

May 12, 2025 -

The Night Hunters Handbook Essential Gear And Strategies

May 12, 2025

The Night Hunters Handbook Essential Gear And Strategies

May 12, 2025

Latest Posts

-

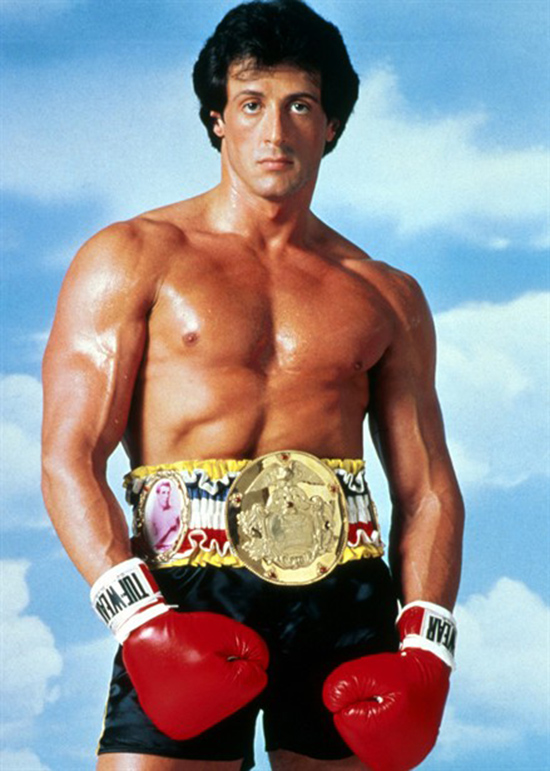

Which Rocky Movie Touches Stallone The Most His Answer Will Surprise You

May 12, 2025

Which Rocky Movie Touches Stallone The Most His Answer Will Surprise You

May 12, 2025 -

Sylvester Stallones Favorite Rocky Movie The Franchises Most Emotional Entry

May 12, 2025

Sylvester Stallones Favorite Rocky Movie The Franchises Most Emotional Entry

May 12, 2025 -

The One Movie Sylvester Stallone Directed But Didnt Star In A Critical And Commercial Failure

May 12, 2025

The One Movie Sylvester Stallone Directed But Didnt Star In A Critical And Commercial Failure

May 12, 2025 -

Action Thriller Armor Starring Sylvester Stallone Free Online Streaming

May 12, 2025

Action Thriller Armor Starring Sylvester Stallone Free Online Streaming

May 12, 2025 -

Sylvester Stallone Action Thriller Armor Now Streaming Free

May 12, 2025

Sylvester Stallone Action Thriller Armor Now Streaming Free

May 12, 2025