Case Study Addendum: BYD's Dominance In Electric Vehicle Battery Production

Table of Contents

BYD's Vertical Integration Strategy: A Key to Success

BYD's unique approach to EV battery production lies in its comprehensive vertical integration strategy. Unlike many competitors who rely on external suppliers for various components and materials, BYD controls the entire supply chain, from raw material sourcing to battery manufacturing and vehicle assembly. This strategic decision has yielded several significant advantages:

- Reduced reliance on external suppliers: This minimizes supply chain risks, ensuring a consistent supply of materials even during periods of global instability or material shortages. This is particularly important given the complexities and potential bottlenecks in sourcing critical materials for EV batteries.

- Enhanced cost control and efficiency: Streamlined operations from raw material processing to final product assembly lead to significant cost savings and improved efficiency throughout the entire production process. This allows BYD to offer competitive pricing in the market.

- Greater control over quality and innovation: BYD's complete control over the supply chain enables them to maintain rigorous quality standards and rapidly implement innovative improvements throughout the entire manufacturing process. This fosters continuous innovation and product improvement.

- Examples: BYD sources its own lithium iron phosphate (LFP) materials, a crucial component of its Blade Batteries, and controls the entire manufacturing process, from cell production to battery pack assembly. This level of control is a key differentiator in the industry. This contrasts sharply with competitors who are more reliant on external suppliers for key components.

Blade Battery Technology: A Game Changer in EV Battery Design

BYD's Blade Battery technology represents a significant advancement in EV battery design. This innovative approach offers several key advantages over traditional battery designs:

- Improved energy density and range: Compared to traditional cylindrical or prismatic cells, Blade Batteries offer significantly improved energy density, resulting in longer driving ranges for electric vehicles. This is a critical factor for consumer adoption.

- Enhanced safety features: The unique cell-to-pack (CTP) design of the Blade Battery enhances safety by reducing the risk of thermal runaway and improving overall structural integrity. The flat, blade-like structure contributes to this superior safety profile.

- Increased space efficiency: The compact design of Blade Batteries allows for greater space efficiency within the vehicle chassis, maximizing interior space and improving overall vehicle design. This optimizes vehicle design and reduces weight.

- Cost-effectiveness: Despite its advanced features, the Blade Battery is surprisingly cost-effective compared to other high-performance EV battery technologies. This makes it a highly competitive option in the market, especially considering its performance characteristics. The use of LFP chemistry also contributes to lower costs.

Market Share and Global Expansion: BYD's Growing Footprint

BYD's market share in the EV battery sector is rapidly expanding. Their strategic global expansion has been instrumental in this growth. BYD is increasingly challenging established players such as CATL and LG Chem.

- Market Share Statistics: BYD's market share is steadily increasing, challenging the longstanding dominance of other major players. Precise figures vary depending on the source and reporting period, but the trend is undeniable.

- Geographic Growth: BYD is experiencing significant growth across various regions globally, including Europe, Asia, and North America. They are strategically expanding their manufacturing facilities and distribution networks.

- Future Expansion Plans: BYD is actively investing in new battery production facilities worldwide, further solidifying its position as a major global player. This reflects their ambitious growth strategy and confidence in market demand.

- Market Strategies: BYD employs diverse strategies tailored to specific regional markets, considering local regulations, consumer preferences, and competitive landscapes. This adaptable approach contributes to their success in diverse global settings.

Challenges and Future Outlook for BYD's Dominance

While BYD's current trajectory is impressive, several challenges lie ahead:

- Increasing Competition: The EV battery market is becoming increasingly competitive, with numerous players vying for market share. This necessitates continuous innovation and adaptation to maintain a leading position.

- Raw Material Price Fluctuations: Fluctuations in the prices of raw materials, such as lithium and cobalt, pose a significant risk to profitability and production stability. Effective supply chain management and diversification strategies are crucial.

- Ongoing Technological Innovation: The need for continuous improvement in battery technology, energy density, charging times, and overall performance is crucial for remaining competitive in this rapidly evolving market. Research and development will play a vital role.

- Environmental Concerns: The environmental impact of battery production and disposal requires careful consideration. Sustainable sourcing of raw materials and responsible recycling programs are necessary to address these concerns.

Conclusion

This case study demonstrates BYD's remarkable success in the rapidly expanding electric vehicle battery production sector. Their vertical integration strategy, innovative Blade Battery technology, and aggressive global expansion have propelled them to a position of market dominance. While challenges remain, BYD's commitment to innovation and efficiency positions them favorably for continued success. To learn more about the future of BYD electric vehicle battery production, and its impact on the EV industry, continue researching the company's advancements and market performance. Understanding the evolution of BYD's battery technology is crucial to comprehending the future of electric mobility.

Featured Posts

-

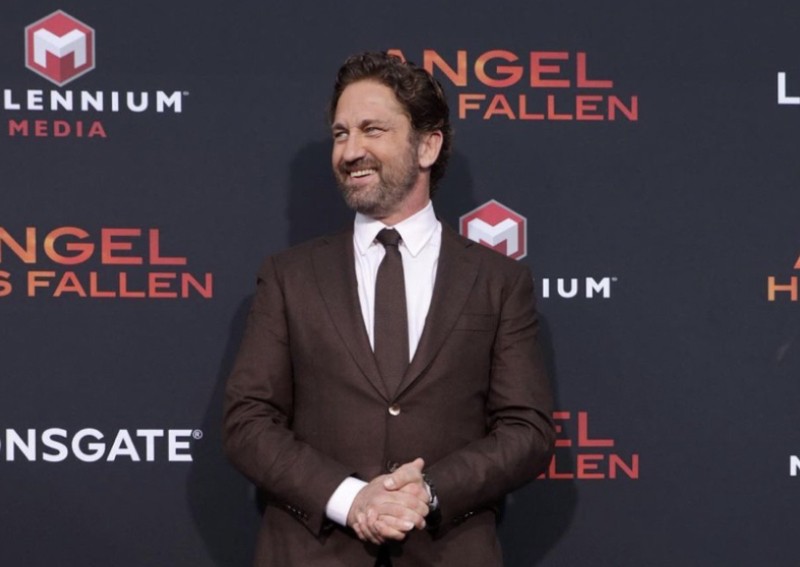

Understanding The Plot Of Angel Has Fallen A Comprehensive Guide

May 13, 2025

Understanding The Plot Of Angel Has Fallen A Comprehensive Guide

May 13, 2025 -

Byd Expands Globally New Markets In Benin Seychelles Croatia Slovakia And Cambodia

May 13, 2025

Byd Expands Globally New Markets In Benin Seychelles Croatia Slovakia And Cambodia

May 13, 2025 -

Free Uefa Europa League Live Streams Manchester United Tottenham Lyon Matches

May 13, 2025

Free Uefa Europa League Live Streams Manchester United Tottenham Lyon Matches

May 13, 2025 -

Hostage Fathers Message Of Strength To His Son

May 13, 2025

Hostage Fathers Message Of Strength To His Son

May 13, 2025 -

Ostapenko Claims Stuttgart Victory Over Sabalenka

May 13, 2025

Ostapenko Claims Stuttgart Victory Over Sabalenka

May 13, 2025