All-American Manufacturing: Overcoming The Hurdles

Table of Contents

The High Cost of Domestic Production

One of the most significant challenges facing All-American manufacturing is the high cost of production compared to many other countries. This high cost stems from several factors, creating a complex web of challenges for American manufacturers.

Rising Labor Costs

American labor costs are significantly higher than in many other countries, impacting competitiveness. This is due to several factors:

- Increased minimum wages and benefits packages: The push for higher minimum wages and comprehensive benefits packages, while beneficial for workers, increases operational costs for manufacturers.

- The need for skilled labor often commands premium salaries: Modern manufacturing increasingly requires a highly skilled workforce, leading to higher salary demands compared to less specialized roles.

- Solutions: To mitigate the impact of rising labor costs, American manufacturers need to explore several strategic options:

- Automation: Investing in automation and robotics can reduce reliance on manual labor, leading to cost savings in the long run.

- Focus on high-value-added manufacturing: Concentrating on producing high-value goods with higher profit margins can offset the higher labor costs.

- Incentivizing workforce training: Investing in and incentivizing robust workforce training programs can upskill the existing workforce, improving productivity and reducing the need for high-cost specialized labor.

Raw Material & Energy Costs

Fluctuations in raw material prices and energy costs further impact the profitability of All-American manufacturing. This volatility creates uncertainty and puts pressure on profit margins.

- Dependence on global supply chains for certain materials: The reliance on global supply chains for many raw materials exposes American manufacturers to price volatility and disruptions.

- The impact of energy prices on operational expenses: Energy costs significantly impact manufacturing operations, making energy efficiency a critical factor in cost control.

- Solutions: Strategies to address these challenges include:

- Investing in domestic sourcing of raw materials: Reducing reliance on foreign sources by developing domestic sources of raw materials strengthens supply chain resilience and reduces price volatility.

- Exploring renewable energy sources: Transitioning to renewable energy sources can reduce reliance on fluctuating fossil fuel prices, lowering energy costs and reducing environmental impact.

- Implementing energy-efficient technologies: Adopting energy-efficient technologies and processes minimizes energy consumption and reduces operational expenses.

Regulations and Compliance

Navigating a complex regulatory landscape adds another layer of cost to All-American manufacturing. While these regulations are crucial for worker safety and environmental protection, they increase the administrative burden and expense for businesses.

- Environmental regulations and compliance requirements: Meeting stringent environmental regulations can be costly, requiring significant investments in pollution control and waste management.

- Safety and labor standards compliance: Maintaining compliance with robust safety and labor standards is essential but adds to operational costs.

- Solutions: To address the challenges of regulations and compliance, several actions can be taken:

- Streamlining regulatory processes: Simplifying and streamlining regulatory processes can reduce administrative burdens and compliance costs.

- Providing clear guidelines and support for businesses: Clear guidelines and readily available support for businesses navigating regulatory requirements can ease the compliance burden.

- Fostering collaboration between industry and regulatory bodies: Collaboration between industry and regulatory bodies can lead to more effective and less burdensome regulations.

Intense Global Competition

All-American manufacturing faces intense competition from manufacturers worldwide, particularly in countries with lower labor and production costs. This competition impacts market share and profitability.

Foreign Market Competition

Businesses face stiff competition from manufacturers in countries with lower labor and production costs. This price differential can make it difficult for American manufacturers to compete on price alone.

- The impact of cheaper imports on domestic market share: The influx of cheaper imports from countries with lower production costs significantly impacts the market share of American manufacturers.

- The challenge of competing with manufacturers in countries with more relaxed regulations: Manufacturers in countries with less stringent regulations often have lower production costs, impacting the competitiveness of American businesses.

- Solutions: To overcome this challenge, American manufacturers must focus on:

- Niche markets: Targeting niche markets where they can offer specialized products and services can allow them to command premium prices and reduce direct competition with low-cost producers.

- Leveraging technology and innovation: Investing in advanced technologies and innovative manufacturing processes can improve efficiency, productivity, and product quality, creating a competitive advantage.

- Promoting "Made in America" branding: Highlighting the quality, durability, and safety of "Made in America" products can attract consumers willing to pay a premium for domestically produced goods.

Supply Chain Disruptions

Global supply chain disruptions have highlighted the vulnerabilities of relying on foreign sources for components and materials. These disruptions can halt production and significantly impact profitability.

- The impact of geopolitical instability and natural disasters on supply chains: Geopolitical instability and natural disasters can severely disrupt global supply chains, leading to production delays and shortages of essential materials.

- The need for increased resilience and diversification of supply sources: Diversifying supply sources and building more resilient supply chains are crucial for mitigating the risks of disruptions.

- Solutions: Strategies to improve supply chain resilience include:

- Reshoring and near-shoring manufacturing: Bringing manufacturing operations back to the US or relocating them to nearby countries reduces reliance on distant, potentially unstable supply chains.

- Investing in domestic supply chain capacity: Investing in domestic capacity for producing key components and materials reduces reliance on foreign suppliers and enhances supply chain security.

- Building strategic partnerships: Building strong, collaborative relationships with domestic suppliers strengthens supply chain resilience and improves responsiveness to disruptions.

Workforce Development Challenges

A significant challenge for All-American manufacturing is developing and maintaining a skilled workforce capable of meeting the demands of modern manufacturing.

Skills Gap

A significant skills gap exists between the skills needed for modern manufacturing jobs and the skills possessed by the available workforce. This gap hinders productivity and competitiveness.

- The need for skilled workers in advanced manufacturing technologies: Modern manufacturing increasingly utilizes advanced technologies such as robotics, automation, and sophisticated software, requiring a workforce with advanced technical skills.

- The lack of interest in manufacturing careers among younger generations: Manufacturing careers are often perceived as less appealing than careers in other sectors, leading to a shortage of skilled workers.

- Solutions: Addressing the skills gap requires a multifaceted approach:

- Investing in vocational training programs: Investing in high-quality vocational training programs provides individuals with the skills needed for modern manufacturing jobs.

- Promoting STEM education: Promoting Science, Technology, Engineering, and Mathematics (STEM) education from a young age can cultivate interest in manufacturing careers and provide a strong foundation for advanced skills.

- Creating apprenticeships and mentorship opportunities: Apprenticeship and mentorship programs provide on-the-job training and guidance, bridging the gap between theoretical knowledge and practical skills.

Attracting and Retaining Talent

The manufacturing industry must compete with other sectors to attract and retain qualified employees. Offering competitive compensation and creating a positive work environment is essential.

- Improving workplace safety and conditions: Creating a safe and positive work environment is crucial for attracting and retaining talent.

- Offering competitive salaries and benefits packages: Offering competitive compensation packages is essential for attracting and retaining skilled workers.

- Solutions: Strategies to attract and retain talent include:

- Creating a positive work environment: Investing in a positive and supportive work environment fosters employee satisfaction and loyalty.

- Highlighting career progression opportunities: Creating clear career paths and opportunities for advancement within the company increases employee retention.

- Emphasizing the importance of manufacturing for the national economy: Highlighting the importance of manufacturing for national economic security and prosperity can attract workers who want to contribute to a meaningful cause.

Conclusion

Revitalizing All-American manufacturing requires a multifaceted approach addressing the high cost of domestic production, intense global competition, and workforce development challenges. By strategically investing in automation, fostering innovation, strengthening domestic supply chains, and developing a highly skilled workforce, the United States can rebuild its manufacturing prowess and ensure its economic competitiveness on the global stage. Let's support the growth of All-American manufacturing through strategic policy changes, targeted investments, and a commitment to the future of American industry. Embrace the power of All-American manufacturing – it's the foundation of a strong and prosperous nation. Invest in the future of All-American manufacturing today!

Featured Posts

-

Black Hawk And Plane Collision Pilot Error Investigation Reveals Two Key Mistakes

Apr 29, 2025

Black Hawk And Plane Collision Pilot Error Investigation Reveals Two Key Mistakes

Apr 29, 2025 -

Attorney General Targets Minnesota Over Transgender Athlete Ban Compliance Deadline Looms

Apr 29, 2025

Attorney General Targets Minnesota Over Transgender Athlete Ban Compliance Deadline Looms

Apr 29, 2025 -

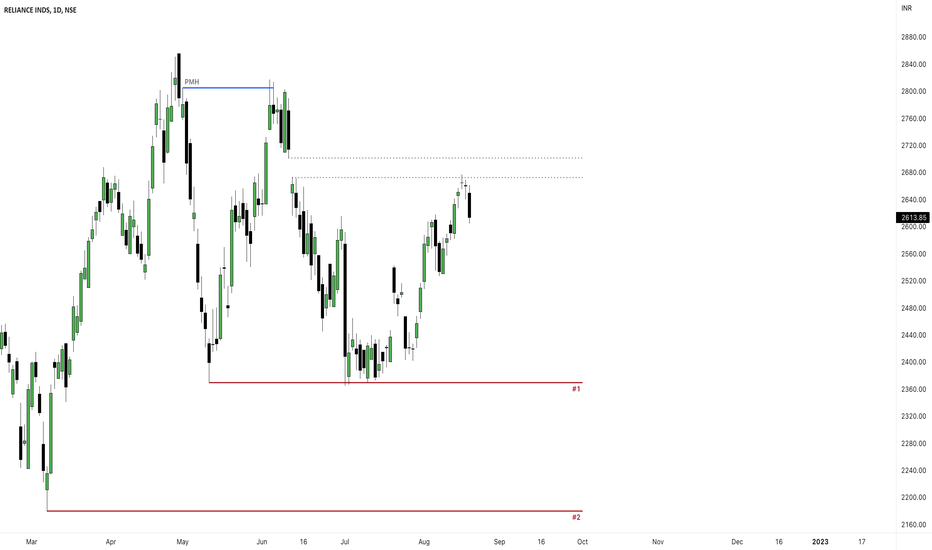

Strong Earnings Drive Reliance Shares To 10 Month Peak

Apr 29, 2025

Strong Earnings Drive Reliance Shares To 10 Month Peak

Apr 29, 2025 -

Louisville Mail Delivery Issues A Union Leaders Statement

Apr 29, 2025

Louisville Mail Delivery Issues A Union Leaders Statement

Apr 29, 2025 -

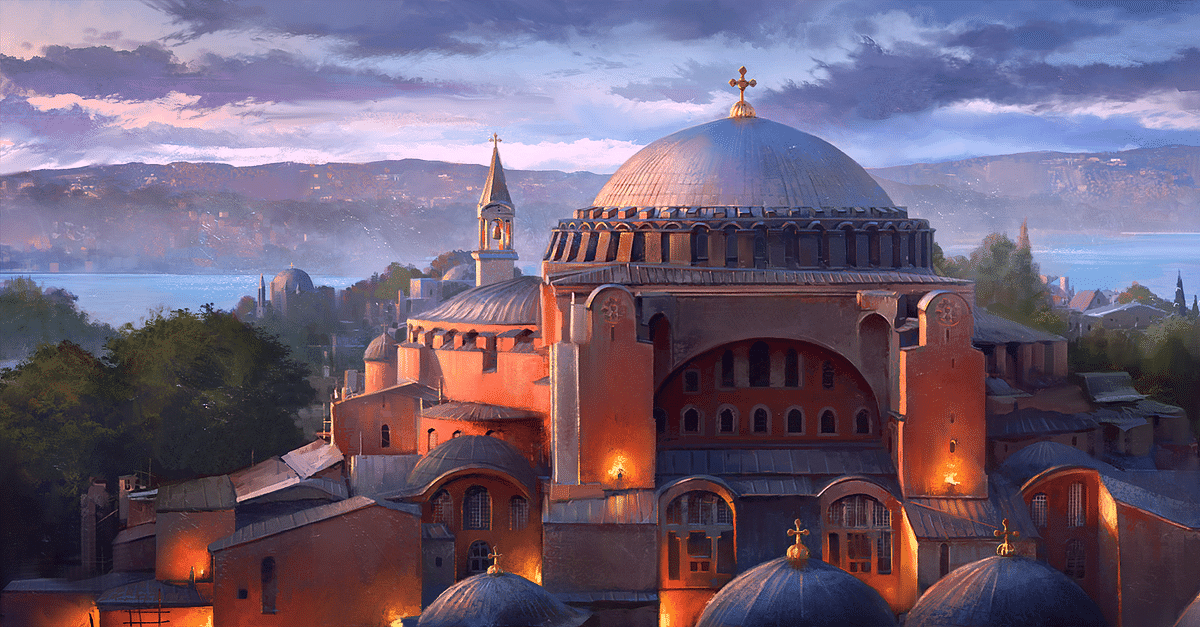

The Hagia Sophia 1600 Years Of History And Resilience

Apr 29, 2025

The Hagia Sophia 1600 Years Of History And Resilience

Apr 29, 2025

Latest Posts

-

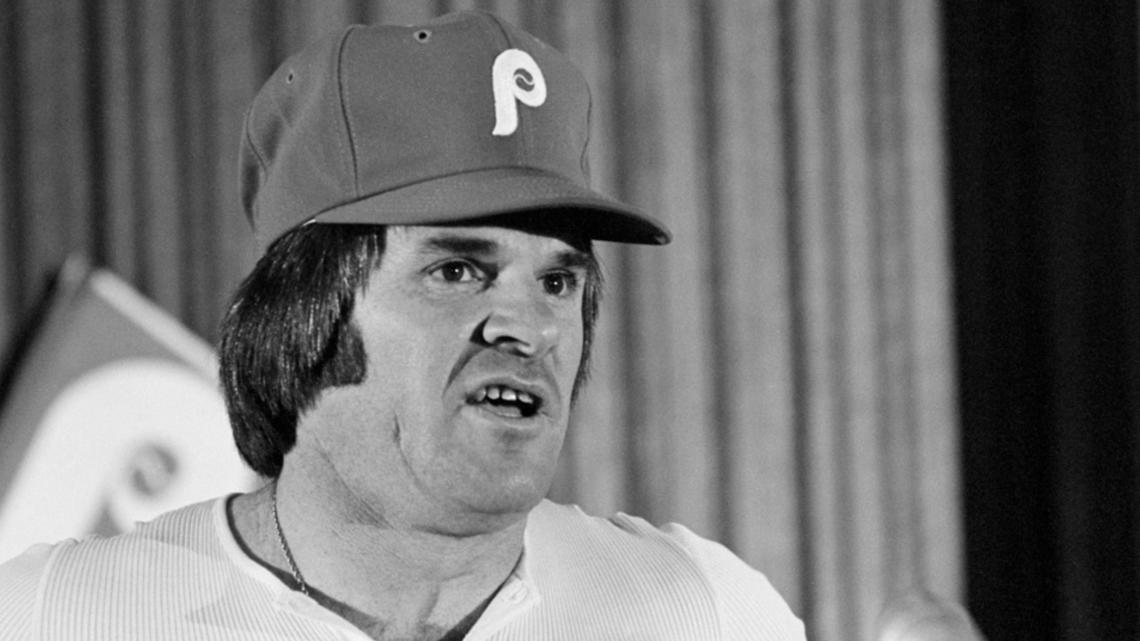

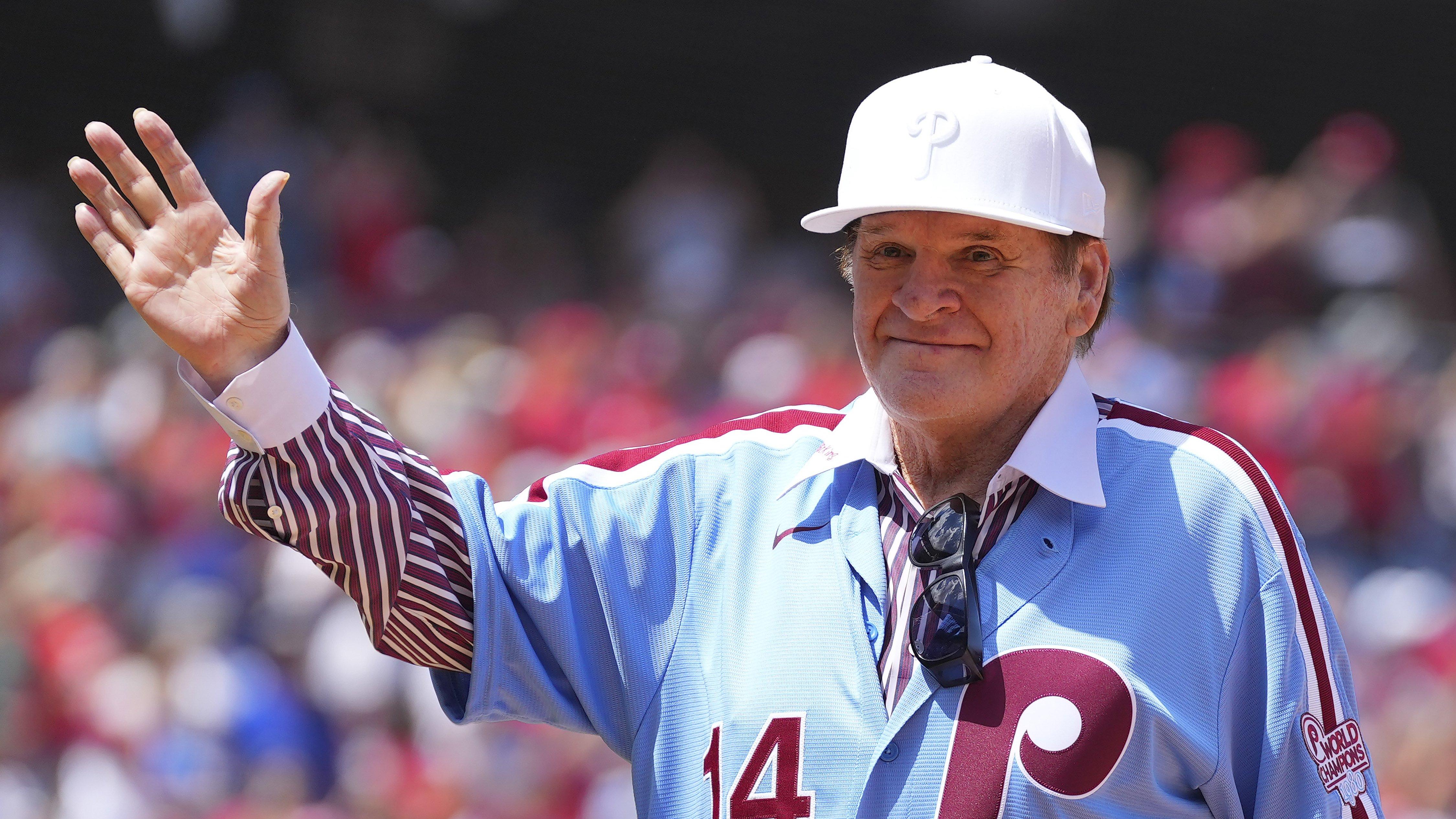

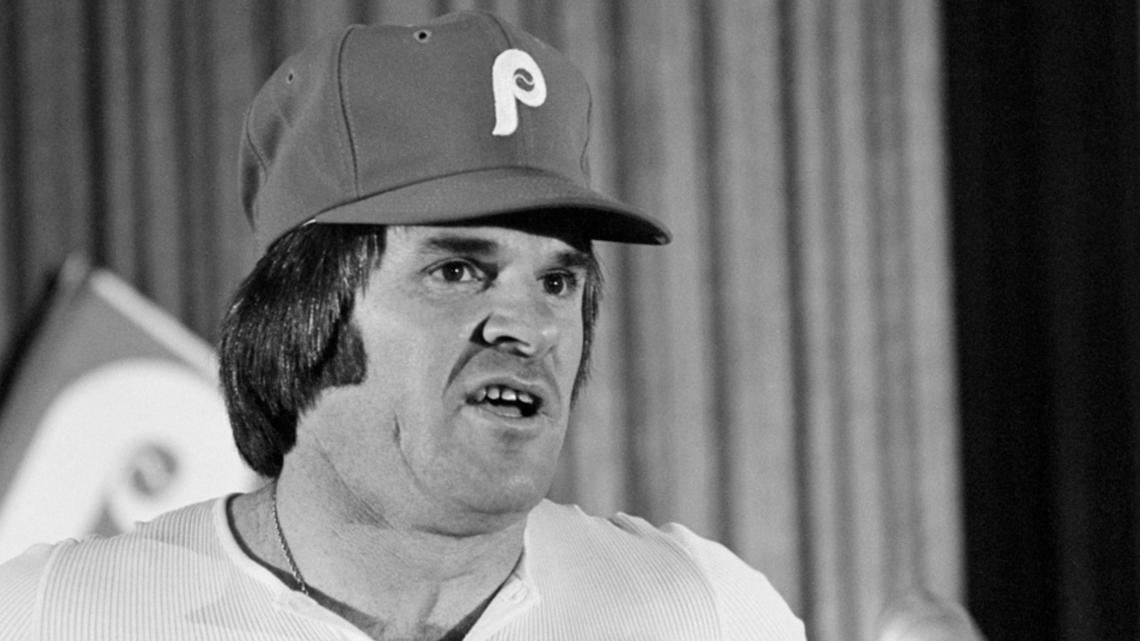

The Pete Rose Pardon Trumps Consideration And The Future Of Baseballs Betting Rules

Apr 29, 2025

The Pete Rose Pardon Trumps Consideration And The Future Of Baseballs Betting Rules

Apr 29, 2025 -

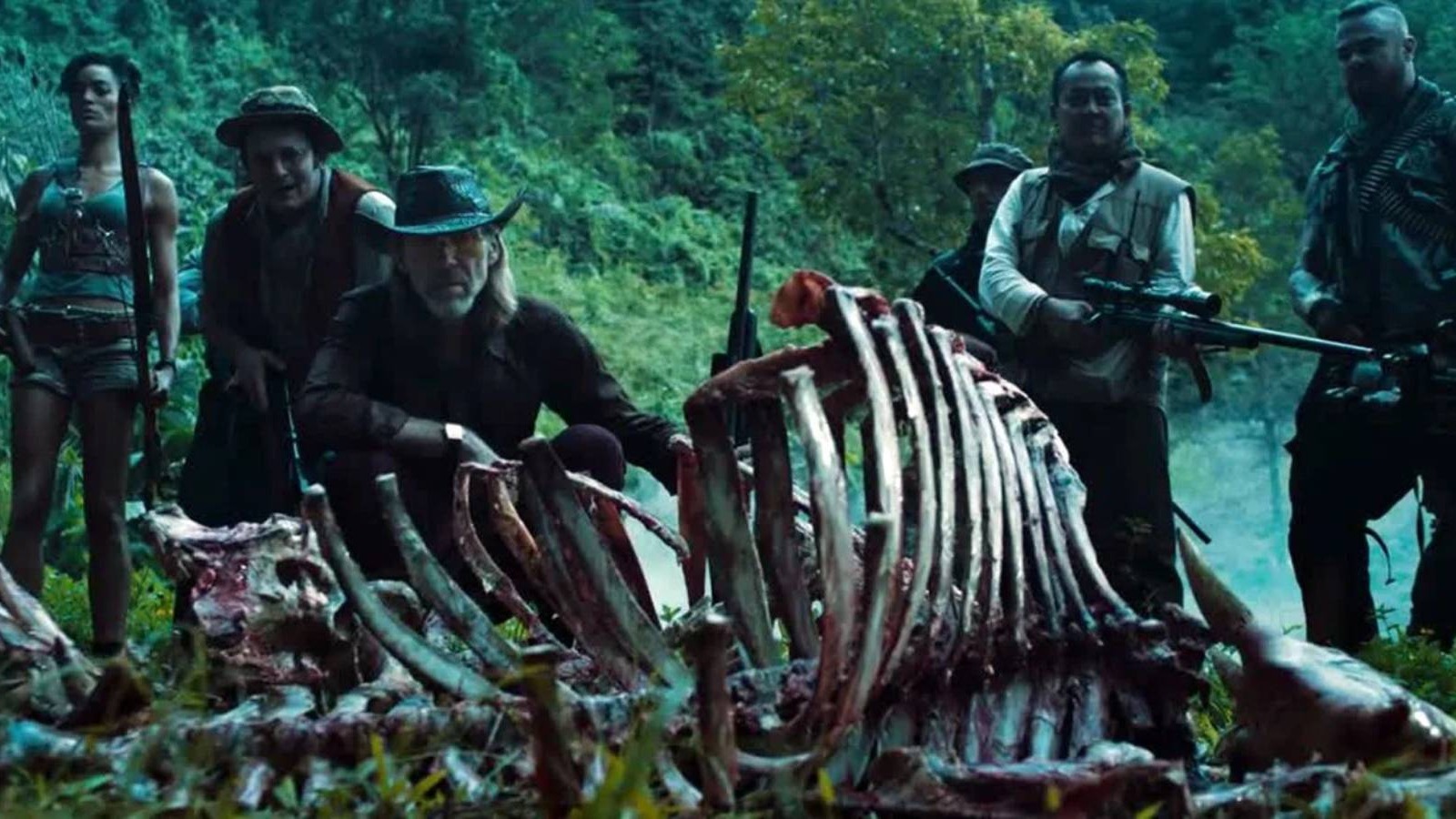

Is A Tremors Series Coming To Netflix Everything We Know

Apr 29, 2025

Is A Tremors Series Coming To Netflix Everything We Know

Apr 29, 2025 -

The Pete Rose Pardon Understanding Trumps Reported Plan

Apr 29, 2025

The Pete Rose Pardon Understanding Trumps Reported Plan

Apr 29, 2025 -

Trumps Potential Pardon Of Pete Rose A Look At The Mlb Ban And Its Implications

Apr 29, 2025

Trumps Potential Pardon Of Pete Rose A Look At The Mlb Ban And Its Implications

Apr 29, 2025 -

Pete Rose Pardon Trumps Plan And Its Implications For Baseball

Apr 29, 2025

Pete Rose Pardon Trumps Plan And Its Implications For Baseball

Apr 29, 2025