AI-Powered Process Safety: A New Patent's Innovative Approach

Table of Contents

Enhanced Predictive Capabilities through AI

AI algorithms are transforming the landscape of process safety management by offering significantly improved predictive capabilities. This new patent utilizes AI to analyze massive datasets from various sources, leading to proactive hazard identification and mitigation.

Real-time Risk Assessment

AI's ability to process and analyze data in real-time provides a significant advantage in risk assessment. By integrating data from sensors, control systems, and historical incident reports, AI algorithms can identify potential hazards before they escalate into incidents. This proactive approach surpasses traditional methods, resulting in:

- Improved accuracy of hazard identification compared to traditional methods: AI can detect subtle patterns and correlations that may be missed by human analysts, leading to more precise and comprehensive risk assessments. This includes identifying previously unknown or under-appreciated hazards.

- Early warning system for potential failures and deviations from normal operating parameters: AI can provide early warnings of potential equipment failures or process deviations, allowing for timely interventions and preventing major incidents. This is particularly valuable in complex processes with numerous interconnected components.

- Integration with existing safety instrumented systems (SIS) for enhanced functionality: AI can seamlessly integrate with existing SIS, augmenting their capabilities and improving their effectiveness. This integration provides a more holistic and comprehensive safety system.

Anomaly Detection and Predictive Maintenance

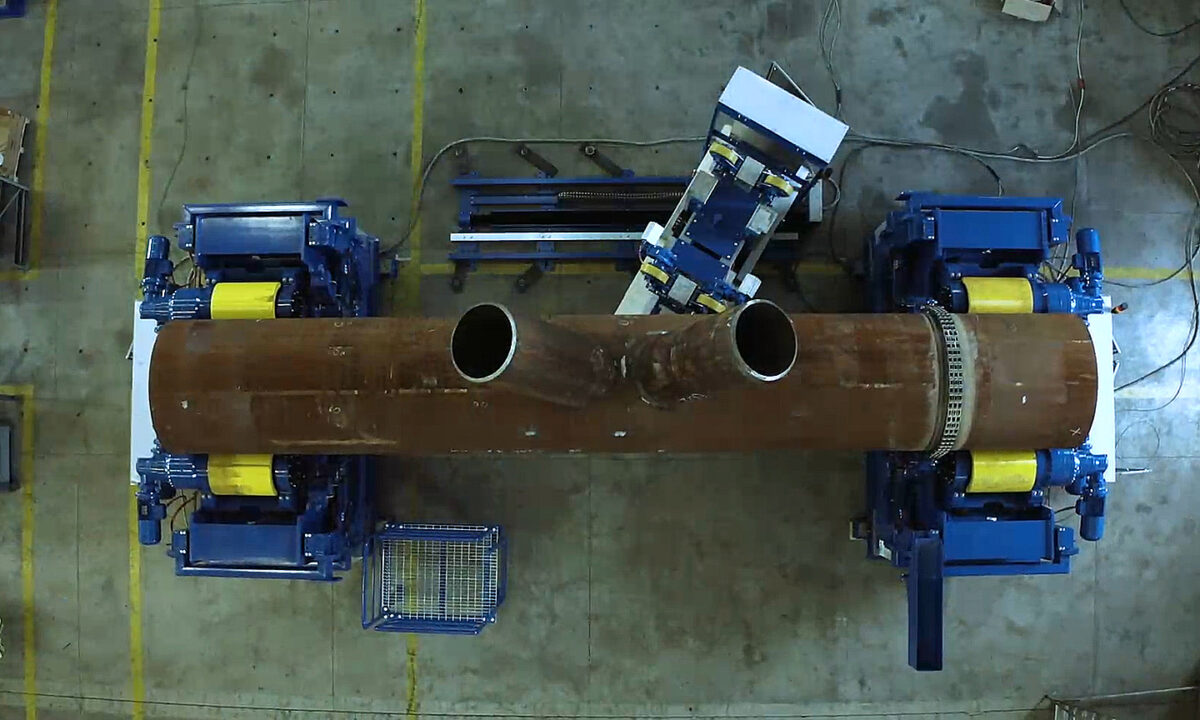

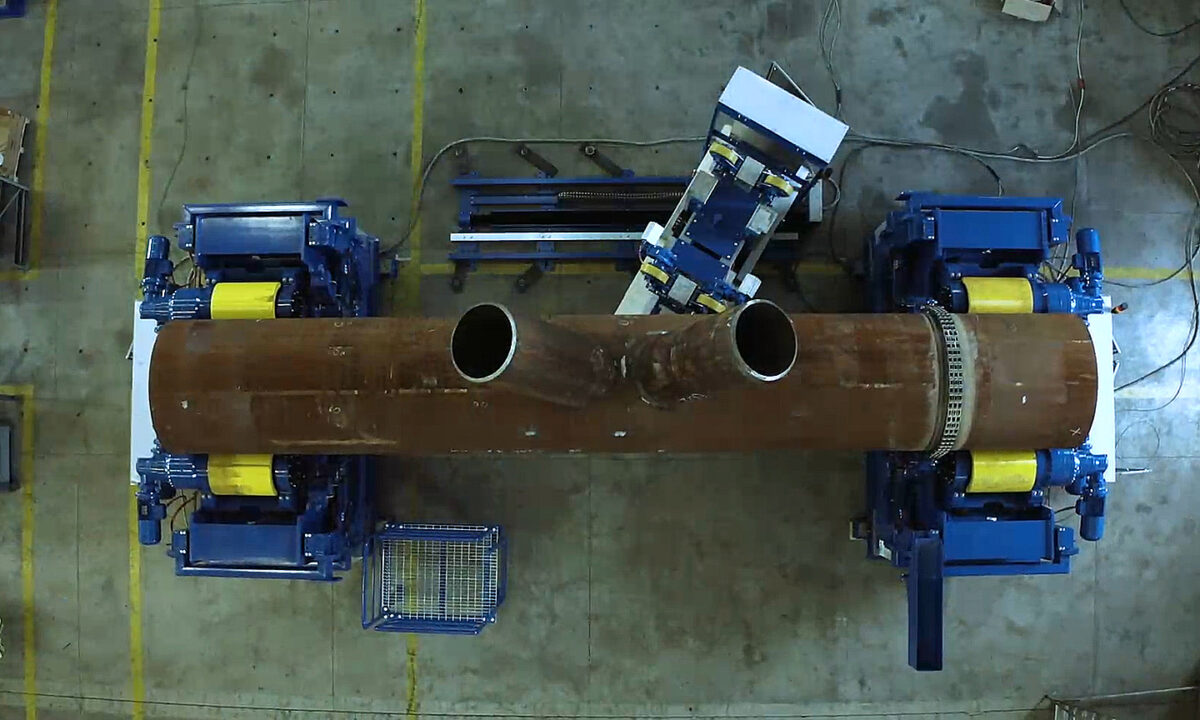

Beyond real-time risk assessment, the patent's AI capabilities extend to anomaly detection and predictive maintenance. By continuously monitoring process data, AI can detect subtle anomalies that may indicate developing equipment malfunctions or process deviations. This enables proactive maintenance, minimizing downtime and maximizing operational efficiency:

- Reduced operational disruptions and unplanned shutdowns: Predictive maintenance reduces the likelihood of unexpected equipment failures, minimizing costly production downtime.

- Optimized maintenance schedules for cost savings: AI-driven maintenance scheduling ensures that maintenance is performed only when necessary, optimizing resource allocation and minimizing costs.

- Prolonged equipment lifespan through preventative measures: By identifying and addressing potential problems early, AI helps extend the lifespan of equipment, reducing the need for premature replacements.

Improved Decision-Making and Operator Support

The patent introduces AI-driven expert systems and automated response systems to significantly improve decision-making and operator support, particularly during critical events. This human-AI collaboration leads to faster, more effective responses to incidents.

AI-Driven Expert Systems

The AI-powered expert systems embedded within the patent's design provide operators with real-time recommendations and support in emergency situations. This assistance significantly improves human decision-making under pressure, minimizing the impact of human error:

- Enhanced operator training through simulated scenarios: AI can create realistic simulated scenarios to train operators and improve their response capabilities in various emergency situations.

- Reduced response times in emergency situations: AI-driven guidance reduces response time by providing immediate, informed recommendations.

- Improved situational awareness and better understanding of complex processes: AI provides a comprehensive overview of the process, enabling operators to better understand the situation and make informed decisions.

Automated Response Systems

The patent details automated safety response systems triggered by AI-driven risk assessments. These systems can automatically initiate crucial actions, minimizing human intervention in critical situations:

- Minimized human intervention in critical situations: Automation reduces the risk of human error in high-pressure situations, ensuring a timely and effective response.

- Faster and more efficient response to emergencies: Automated systems react far quicker than humans, potentially preventing escalating incidents.

- Improved safety outcomes by automating critical actions: Automated responses ensure consistent and effective safety measures are implemented, leading to improved overall safety outcomes.

Data-Driven Safety Improvements and Continuous Learning

The patent emphasizes the importance of data analysis for continuous improvement in process safety. AI facilitates the collection, analysis, and interpretation of this data, leading to ongoing refinements and improvements in safety protocols.

Data Analysis and Reporting

AI-powered data analysis tools within the patent can identify trends, patterns, and weaknesses in existing safety protocols, leading to more effective strategies:

- Improved identification of process safety weaknesses: AI can uncover hidden vulnerabilities in existing systems that may be missed by traditional methods.

- Data-driven recommendations for safety improvements: AI provides evidence-based recommendations for improvements, leading to more effective and targeted safety interventions.

- Creation of more robust and resilient safety protocols: By continuously analyzing data and identifying weaknesses, AI helps create more robust and resilient safety protocols.

Machine Learning for Adaptive Safety

The AI systems incorporated in the patent leverage machine learning to adapt and improve over time. This continuous learning process ensures the system remains effective even as operating conditions and processes change:

- Improved safety performance over time: As the AI learns from new data and experiences, its ability to predict and prevent accidents continuously improves.

- Adaptability to changing operating conditions and processes: The system adapts to changes in the operating environment, maintaining its effectiveness.

- Continuous improvement in safety protocols based on ongoing data analysis: The system continuously refines safety protocols based on new information, ensuring long-term effectiveness.

Conclusion

This new patent on AI-powered process safety represents a significant advancement in industrial safety technology. By combining real-time risk assessment, predictive maintenance, and AI-driven decision support, it promises to significantly reduce the risk of accidents and improve overall safety performance in various industries, including manufacturing, oil and gas, and chemical processing. The innovative approach outlined in the patent offers a pathway towards a safer and more efficient future. To learn more about this revolutionary technology and how it can benefit your organization, explore the patent details and consider integrating AI-powered process safety solutions into your operations. Implementing AI process safety management systems will be critical for maintaining competitiveness in today's landscape.

Featured Posts

-

German Coalition Negotiations Deal Expected By Midday

Apr 30, 2025

German Coalition Negotiations Deal Expected By Midday

Apr 30, 2025 -

Independent Office For Police Conduct Iopc Challenges Bbcs Chris Kaba Panorama

Apr 30, 2025

Independent Office For Police Conduct Iopc Challenges Bbcs Chris Kaba Panorama

Apr 30, 2025 -

Gillian Anderson And A Possible X Files Reboot Update From Ryan Coogler

Apr 30, 2025

Gillian Anderson And A Possible X Files Reboot Update From Ryan Coogler

Apr 30, 2025 -

Processo Becciu Appello Dal 22 Settembre Dichiarazione Di Innocenza

Apr 30, 2025

Processo Becciu Appello Dal 22 Settembre Dichiarazione Di Innocenza

Apr 30, 2025 -

German Coalition Deal Imminent Midday Announcement Sources Report

Apr 30, 2025

German Coalition Deal Imminent Midday Announcement Sources Report

Apr 30, 2025