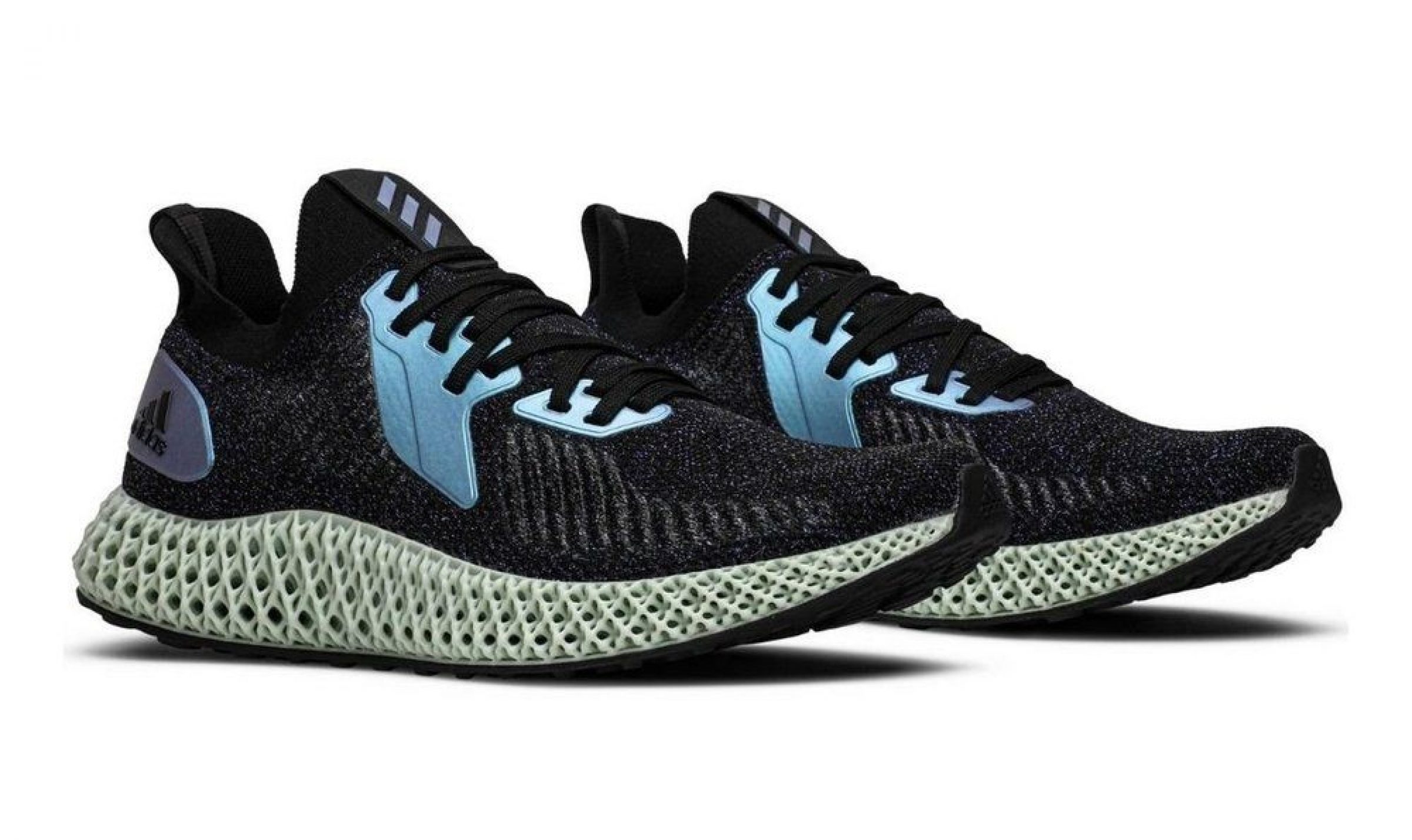

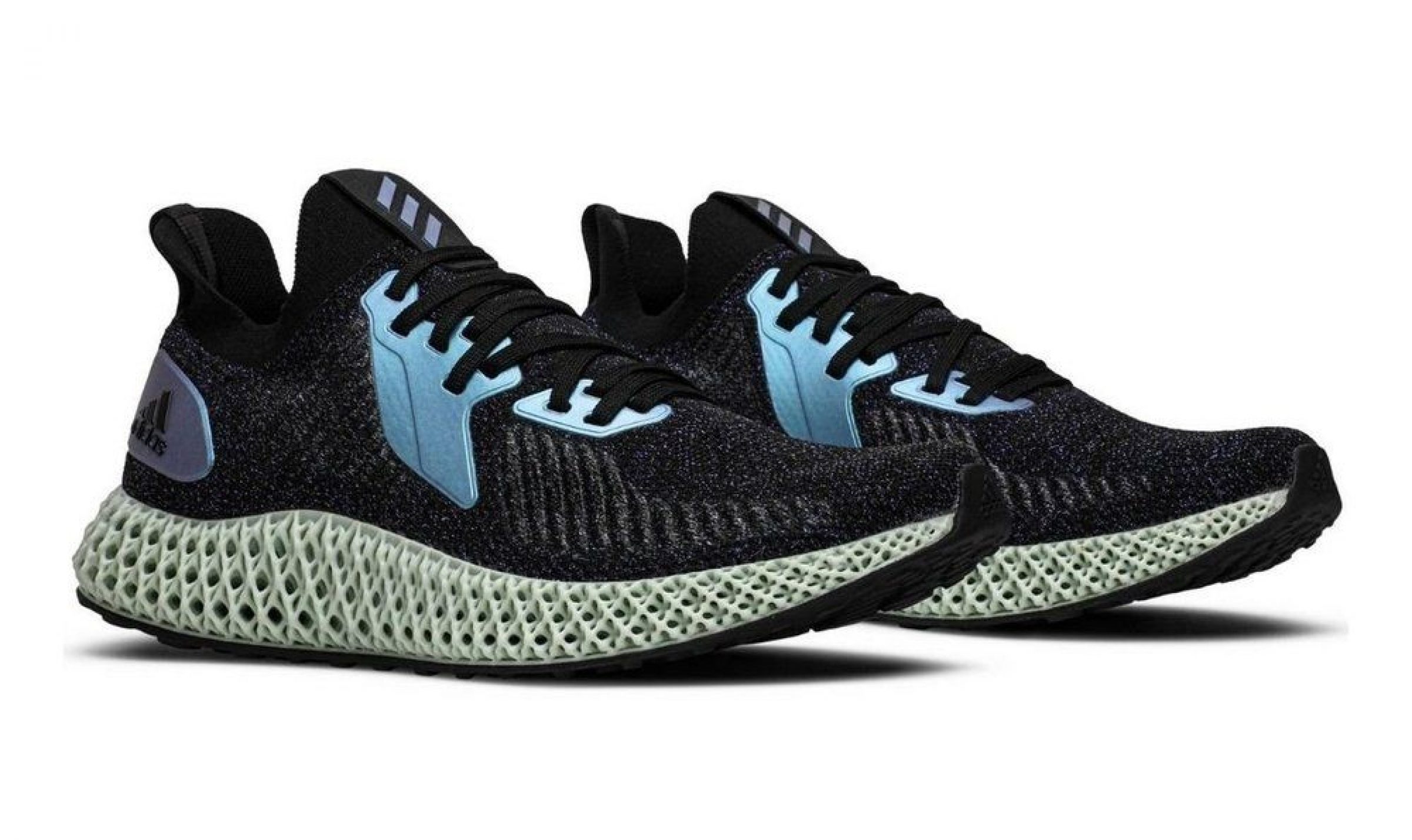

Adidas 3D-Printed Shoes: Performance, Comfort, And Design Analysis

Table of Contents

Performance of Adidas 3D-Printed Shoes

Enhanced Support and Stability

The precise construction methods inherent in 3D printing allow for customized midsoles in Adidas 3D-printed shoes, resulting in superior support and stability. This is a significant advantage for athletes and active individuals.

- Adidas Futurecraft 4D: Features a lattice-like midsole structure providing targeted cushioning and support based on data-driven design.

- Adidas Ultraboost DNA CC_1: Showcases the potential of 3D-printed midsoles for creating unique and adaptive support structures.

- Studies have shown that 3D-printed midsoles offer improved shock absorption and energy return compared to traditionally manufactured midsoles, leading to better running performance and reduced risk of injury. This enhanced "cushioning" and "support" contributes to overall "stability" during athletic activities.

Lightweight Design and Agility

3D printing allows for the creation of complex, lightweight designs that would be impossible to achieve through traditional manufacturing. This results in shoes that enhance agility and speed.

- Compared to traditional running shoes, many Adidas 3D-printed models are significantly lighter, reducing fatigue and improving responsiveness.

- The use of lightweight materials like TPU in the 3D-printed midsoles contributes significantly to the overall "lightweight shoes" design.

- This reduction in weight translates directly to improved "agility" and "speed," particularly beneficial for runners and other athletes focusing on performance. The innovative "material innovation" is key to this aspect.

Comfort Features in Adidas 3D-Printed Shoes

Customized Fit and Comfort

One of the most significant advantages of Adidas 3D-printed shoes is the potential for a truly personalized fit. Through 3D scanning technology, Adidas can create shoes tailored to the unique contours of an individual's foot.

- The 3D scanning process captures precise measurements of the foot, ensuring a perfect fit.

- This personalized approach leads to enhanced comfort and minimizes the risk of blisters or other discomfort associated with ill-fitting shoes.

- User feedback consistently points to the exceptional comfort and fit provided by these "personalized fit" shoes, highlighting the importance of "ergonomics" in footwear design.

Breathable Materials and Breathability

Adidas incorporates breathable materials in the design of its 3D-printed shoes to enhance comfort, particularly during extended periods of wear.

- Many models utilize breathable mesh materials in the upper to allow for better air circulation.

- This "ventilation" helps regulate temperature and prevent the buildup of moisture, keeping the feet cool and dry. This contributes to improved "comfort" and overall performance.

- The choice of "breathable materials" is critical in ensuring that the shoes are comfortable for various activities and weather conditions.

Design and Aesthetics of Adidas 3D-Printed Shoes

Innovative Design and Customization Options

Adidas 3D-printed shoes stand out for their unique and futuristic designs, showcasing the creative potential of this innovative manufacturing process.

- The ability to create complex geometric patterns and intricate structures allows for truly unique and eye-catching shoe designs.

- Some models offer "custom design" options, allowing consumers to personalize their shoes with unique colors or patterns.

- Collaborations with designers and artists further enhance the aesthetic appeal and "style" of Adidas 3D-printed footwear.

Sustainability and Eco-Conscious Design

3D printing offers a potential pathway towards more sustainable footwear manufacturing by reducing waste and optimizing material usage.

- Unlike traditional shoe manufacturing, 3D printing minimizes material waste by only producing the necessary amount of material.

- This "waste reduction" contributes to a lower environmental impact.

- Adidas' commitment to "sustainable footwear" is evident in its ongoing research and development in this area, focusing on eco-friendly manufacturing processes.

Conclusion

Adidas 3D-printed shoes represent a significant leap forward in footwear technology. Their superior performance, enhanced comfort, and innovative designs highlight the potential of 3D printing to revolutionize the industry. The key takeaways are improved athletic performance due to enhanced support and stability, increased comfort through customized fit and breathable materials, and a focus on sustainable and eco-conscious design practices. Discover the future of footwear with Adidas 3D-printed shoes today! Explore the latest models and experience the ultimate in performance and comfort with Adidas' innovative 3D-printed shoe technology by visiting the Adidas website or your favorite retailer.

Featured Posts

-

Conor Mc Gregors Fox News Appearance Public Opinion

May 12, 2025

Conor Mc Gregors Fox News Appearance Public Opinion

May 12, 2025 -

Rethinking John Wick 5 A Critical Analysis Of Franchise Continuation

May 12, 2025

Rethinking John Wick 5 A Critical Analysis Of Franchise Continuation

May 12, 2025 -

Fox News Defamation Suit Ray Epps And The January 6th Narrative

May 12, 2025

Fox News Defamation Suit Ray Epps And The January 6th Narrative

May 12, 2025 -

The Evolution Of Mtv Cribs Tracking Celebrity Homes And Lifestyles

May 12, 2025

The Evolution Of Mtv Cribs Tracking Celebrity Homes And Lifestyles

May 12, 2025 -

100 000 Up For Grabs B And W Trailer Hitches All Star Bass Fishing Tournament

May 12, 2025

100 000 Up For Grabs B And W Trailer Hitches All Star Bass Fishing Tournament

May 12, 2025

Latest Posts

-

Investigasi Foto Jaringan Penipuan Online Global Di Myanmar Mengungkap Nasib Pekerja Indonesia

May 13, 2025

Investigasi Foto Jaringan Penipuan Online Global Di Myanmar Mengungkap Nasib Pekerja Indonesia

May 13, 2025 -

Foto Tragedi Myanmar Ribuan Pekerja Korban Penipuan Online Internasional Termasuk Wni

May 13, 2025

Foto Tragedi Myanmar Ribuan Pekerja Korban Penipuan Online Internasional Termasuk Wni

May 13, 2025 -

Ekspose Foto Jebakan Penipuan Online Internasional Di Myanmar Libatkan Warga Indonesia

May 13, 2025

Ekspose Foto Jebakan Penipuan Online Internasional Di Myanmar Libatkan Warga Indonesia

May 13, 2025 -

Potret Pilu Ribuan Pekerja Terperangkap Penipuan Online Internasional Di Myanmar Ada Wni

May 13, 2025

Potret Pilu Ribuan Pekerja Terperangkap Penipuan Online Internasional Di Myanmar Ada Wni

May 13, 2025 -

Foto Ribuan Pekerja Terjebak Jaringan Penipuan Online Myanmar Warga Indonesia Jadi Korban

May 13, 2025

Foto Ribuan Pekerja Terjebak Jaringan Penipuan Online Myanmar Warga Indonesia Jadi Korban

May 13, 2025