5% Of Manufacturers Invest Heavily In Cybersecurity: 2025 Trends

Table of Contents

A staggering statistic reveals the vulnerability of the manufacturing sector: Cyberattacks cost manufacturers an average of $2.1 million per incident, leading to significant downtime and reputational damage. This underscores the urgent need for robust manufacturing cybersecurity. While the digital transformation of manufacturing offers incredible opportunities, it also expands the attack surface, making comprehensive security paramount. The reality, however, is stark: only 5% of manufacturers are investing heavily in cybersecurity, creating a significant vulnerability for the industry as a whole. This article will explore the rising tide of cyber threats, the barriers hindering widespread investment, and the key trends shaping manufacturing cybersecurity in 2025, offering a path forward for improved protection.

2. Main Points:

H2: The Rising Tide of Cyber Threats in the Manufacturing Sector

The manufacturing landscape faces an increasingly sophisticated and persistent threat landscape. Cyberattacks are no longer isolated incidents; they are evolving, becoming more targeted and devastating in their impact.

H3: Increased sophistication of attacks: Modern cyberattacks against manufacturers leverage advanced techniques, far beyond simple malware. We're seeing a rise in:

- Ransomware attacks: Crippling operations by encrypting critical data and demanding ransoms for its release. The NotPetya ransomware attack in 2017, for instance, caused billions of dollars in damage globally, significantly impacting manufacturing firms.

- IoT vulnerabilities: The proliferation of connected devices (IoT) in manufacturing environments creates numerous entry points for attackers. Compromised sensors, PLCs, or industrial robots can be leveraged to disrupt operations or steal valuable data.

- Supply chain attacks: Attackers are increasingly targeting manufacturers' suppliers to gain access to their networks. Compromising a supplier can provide a backdoor into the entire supply chain.

- AI-powered attacks: The use of artificial intelligence by attackers is increasing, enabling more automated and sophisticated attacks that are harder to detect and defend against.

H3: Expanding attack surface: The integration of advanced technologies like cloud computing, Industrial IoT (IIoT), and automation dramatically expands the attack surface for manufacturers.

- Vulnerable devices and systems: Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, and industrial robots are all potential targets, each representing a critical point of failure. Legacy systems, often lacking modern security features, present particularly significant challenges.

- Cloud connectivity: While offering benefits, cloud adoption also increases the risk of data breaches and unauthorized access if not properly secured.

- Remote access vulnerabilities: The increased reliance on remote access for maintenance and operations creates new attack vectors that must be secured effectively.

H3: Regulatory compliance and potential fines: Governments worldwide are increasingly enforcing stricter cybersecurity regulations for manufacturers. Non-compliance can lead to severe penalties.

- GDPR, CCPA, and other regulations: These regulations mandate specific cybersecurity measures and impose hefty fines for data breaches and non-compliance.

- NIST Cybersecurity Framework: This framework provides guidelines for building a robust cybersecurity posture, which many manufacturers are adopting as a best practice.

- Industry standards: Compliance with industry-specific standards and certifications (e.g., ISO 27001) is becoming crucial for demonstrating a commitment to cybersecurity.

H2: Why Only 5% Invest Heavily in Manufacturing Cybersecurity: Barriers to Adoption

Despite the clear and present danger, a significant barrier exists preventing widespread investment in robust cybersecurity solutions.

H3: Cost and budget constraints: Implementing comprehensive cybersecurity measures requires a significant financial investment.

- Software and hardware costs: Investing in security information and event management (SIEM) systems, endpoint detection and response (EDR) solutions, and other advanced technologies can be expensive.

- Personnel costs: Hiring and retaining skilled cybersecurity professionals is crucial but comes at a considerable cost.

- ROI challenges: Demonstrating a clear return on investment (ROI) for cybersecurity initiatives can be difficult, leading to reluctance to invest. However, the cost of a successful attack far outweighs the cost of prevention.

H3: Lack of skilled cybersecurity professionals: A severe shortage of cybersecurity professionals with experience in the manufacturing sector hinders progress.

- Recruitment difficulties: Finding individuals with the necessary skills and experience is challenging, leading to competition and high salaries.

- Retention challenges: Attracting and retaining skilled professionals requires competitive compensation and opportunities for growth.

- Upskilling initiatives: Investing in training and upskilling programs for existing employees can help address the skills gap.

H3: Resistance to change and lack of awareness: Many manufacturers struggle with adopting new technologies and processes due to concerns about disruption and cost.

- Misconceptions about cybersecurity: Some manufacturers underestimate the risk of cyberattacks or believe that their operations are too small to be targeted.

- Lack of executive buy-in: A lack of strong leadership support for cybersecurity initiatives can hinder implementation efforts.

- Fear of change: Reluctance to adopt new security practices due to perceived complexity or disruption.

H2: 2025 Trends in Manufacturing Cybersecurity: A Path Forward

To address these challenges and improve security posture, several trends are emerging in manufacturing cybersecurity:

H3: Increased adoption of AI and machine learning: AI and ML are transforming cybersecurity by enabling more proactive threat detection and response.

- AI-powered threat detection: AI algorithms can analyze massive datasets to identify anomalies and potential threats, enhancing early detection capabilities.

- Automated incident response: AI can automate incident response processes, minimizing the impact of attacks.

- Predictive analytics: Predictive analytics can help identify potential vulnerabilities and risks before they can be exploited.

H3: Zero Trust architecture: Moving beyond traditional perimeter-based security, a Zero Trust model assumes no implicit trust and verifies every user and device before granting access.

- Microsegmentation: Dividing the network into smaller, isolated segments limits the impact of a breach.

- Multi-factor authentication: Implementing strong multi-factor authentication safeguards against unauthorized access.

- Continuous monitoring and verification: Continuously monitoring user activity and system behavior helps detect and respond to threats in real-time.

H3: Enhanced cybersecurity training and awareness programs: Investing in employee training and awareness programs is crucial for building a strong security culture.

- Phishing simulations: Conducting regular phishing simulations helps employees recognize and avoid phishing attacks.

- Security awareness training: Providing employees with regular security awareness training helps improve their understanding of cybersecurity threats and best practices.

- Security champions: Appointing security champions within the organization helps promote a security culture.

3. Conclusion: Securing the Future of Manufacturing Through Enhanced Cybersecurity

The rising tide of cyber threats necessitates a fundamental shift in how manufacturers approach cybersecurity. The barriers to adoption—cost, skills shortages, and resistance to change—must be overcome. Embracing the trends discussed—AI/ML, Zero Trust, and enhanced training—is crucial for strengthening defenses. Don't be one of the 95%; invest in robust manufacturing cybersecurity solutions today. Learn more about securing your operations and preventing costly cyberattacks by exploring resources like the NIST Cybersecurity Framework and industry best practices. Proactive investment in manufacturing cybersecurity is not just a cost; it's an investment in the future resilience and success of your organization.

Featured Posts

-

Scarlett Johansson A Marvel Univerzum Visszaterese Es A Kult Film

May 13, 2025

Scarlett Johansson A Marvel Univerzum Visszaterese Es A Kult Film

May 13, 2025 -

Top Filmov S Dzherardom Batlerom Mnenie Eksperta

May 13, 2025

Top Filmov S Dzherardom Batlerom Mnenie Eksperta

May 13, 2025 -

Philadelphia 76ers Nba Draft Lottery Odds Viewing Details And Analysis

May 13, 2025

Philadelphia 76ers Nba Draft Lottery Odds Viewing Details And Analysis

May 13, 2025 -

Lids Una Ted I Barnli Nov Zhivot Vo Premier Ligata

May 13, 2025

Lids Una Ted I Barnli Nov Zhivot Vo Premier Ligata

May 13, 2025 -

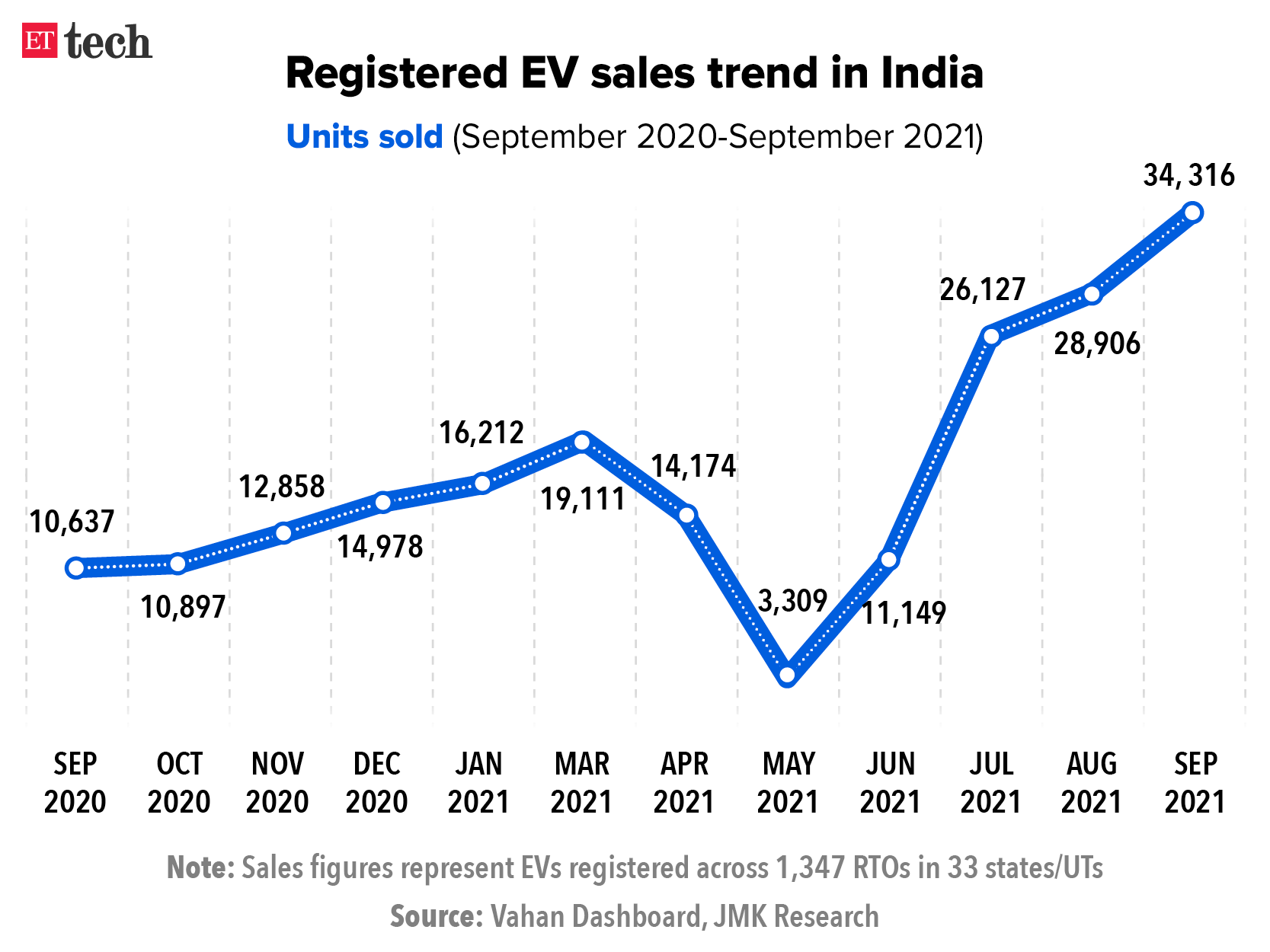

Brazils Ev Market Byds Expansion And Fords Shrinking Footprint

May 13, 2025

Brazils Ev Market Byds Expansion And Fords Shrinking Footprint

May 13, 2025

Latest Posts

-

Final Seals Depart As Pieterburens Seal Rescue Center Closes

May 13, 2025

Final Seals Depart As Pieterburens Seal Rescue Center Closes

May 13, 2025 -

End Of An Era Pieterburen Releases Last Seals Before Permanent Closure

May 13, 2025

End Of An Era Pieterburen Releases Last Seals Before Permanent Closure

May 13, 2025 -

Pieterburen Seal Rescue Center Closes After 50 Years Final Seals Released

May 13, 2025

Pieterburen Seal Rescue Center Closes After 50 Years Final Seals Released

May 13, 2025 -

Schiphol Road And Ferry Travel Prepare For Congestion This Easter Holiday

May 13, 2025

Schiphol Road And Ferry Travel Prepare For Congestion This Easter Holiday

May 13, 2025 -

Heavy Traffic Anticipated Schiphol Roads And Ferries During Easter And Spring Break

May 13, 2025

Heavy Traffic Anticipated Schiphol Roads And Ferries During Easter And Spring Break

May 13, 2025